Software driver and software device

A technology of software drivers and driving devices, which is applied in the direction of program-controlled manipulators, manufacturing tools, manipulators, etc., can solve the problems of software robot application limitations, and achieve the effects of quick output response, simple structure, and strong pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

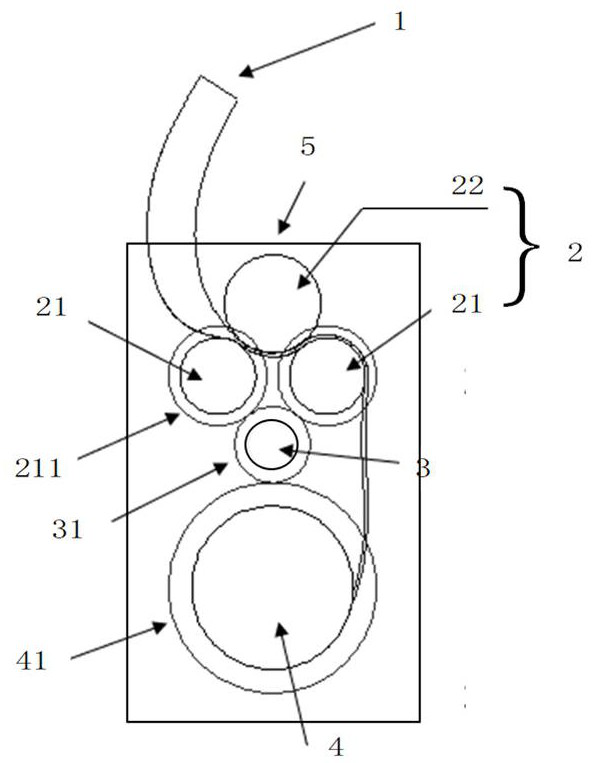

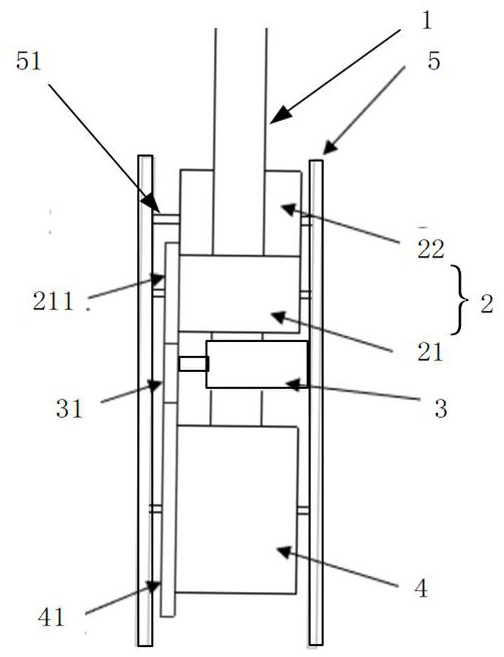

[0066] refer to Figure 1-4 , this embodiment provides a software driver, including a hose 1 , a transmission component 2 , and a driving device 3 . Among them, the inner cavity of the hose 1 is filled with fluid; one end of the hose 1 is passed through the inside of the transmission part 2; the driving device 3 is connected to the transmission part 2, and the driving device 3 can drive the movement of the transmission part 2 to drive the hose 1 Move relative to the transmission part 2; when the hose 1 retracts into the transmission part 2 along the first direction, the transmission part 2 squeezes the hose 1 and squeezes the fluid in the hose 1 out of the hose 1; when the hose 1 moves along When the second direction extends out of the transmission part 2 , the extruded fluid flows back into the hose 1 .

[0067] Wherein, the first direction is the direction in which the hose 1 retracts into the transmission part 2;

[0068] In this embodiment, the transmission part 2 has tw...

Embodiment 2

[0080] This embodiment is further refined on the basis of embodiment one, refer to Figure 1-2 , the software driver also includes: a rolling component 4. The rolling part 4 may be a tube rolling wheel. Wherein, one end of the hose 1 passing through the transmission part 2 is sealed and fixed to the rolling part 4; the first gear 31 of the driving device 3 is engaged with the third gear 41 of the rolling part 4, and the driving device 3 can drive the scrolling The part 4 winds the hose 1 squeezed by the conveying part 2 on the rolling part 4 .

[0081] In this embodiment, through the setting of the rolling part 4, on the one hand, the hose 1 squeezed by the transmission part 2 can be rolled on the rolling part 4 to store the hose 1 neatly, which has the advantages of saving space and reducing software. The effect of the volume of the driver; on the other hand, when the rolling part 4 rotates, the hose 1 can also be pulled to improve the efficiency of the hose 1 retracting in...

Embodiment 3

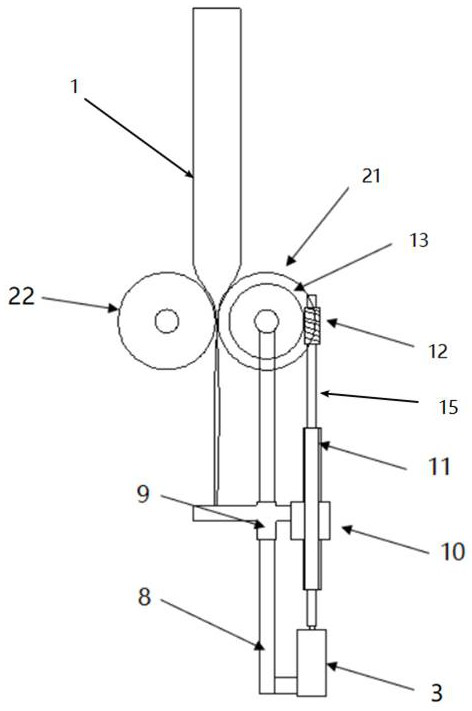

[0088] This embodiment is further refined on the basis of Embodiment 1, such as image 3 As shown, the software driver also includes: a pillar 8, a transmission rod 15 and a linear slider 9; wherein, the pillar 8 is arranged in parallel with the transmission rod 15; the linear slider 9 is threaded through the pillar 8; the transmission rod 15 is connected to the driving device 3, The transmission rod 15 is provided with a first transmission part and a second transmission part in turn; one end of the hose 1 passing through the transmission part 2 is connected to one end of the linear slider 9; the other end of the first transmission part is connected to the linear slider 9; The transmission part is connected to the transmission part 2; the driving device 3 can drive the transmission rod 15 to rotate, so as to drive the first transmission part to drive the linear slider 9 to make a linear motion on the pillar 8, and when the linear slider 9 makes a linear motion, it drives the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com