Ultrasonic cleaning device

A cleaning device and ultrasonic cleaning technology, applied in the field of ultrasonic cleaning, can solve the problems of reduced cleaning effect, damage to the ultrasonic cleaning device, and inability to remove dust and stains in advance, so as to avoid waste of manpower and water resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

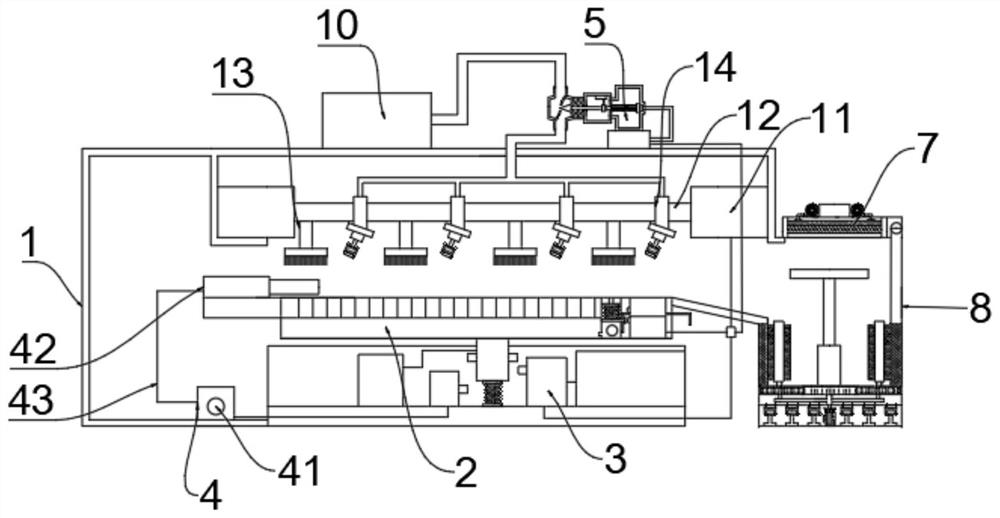

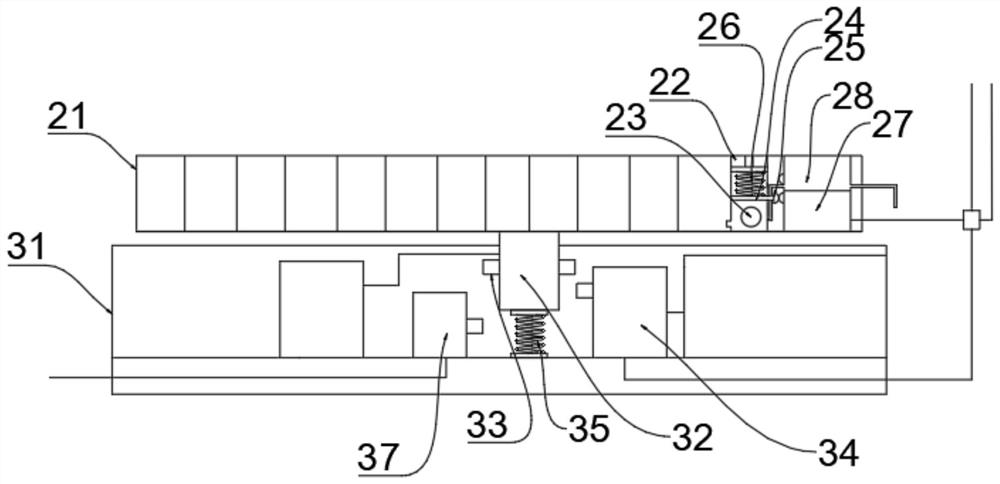

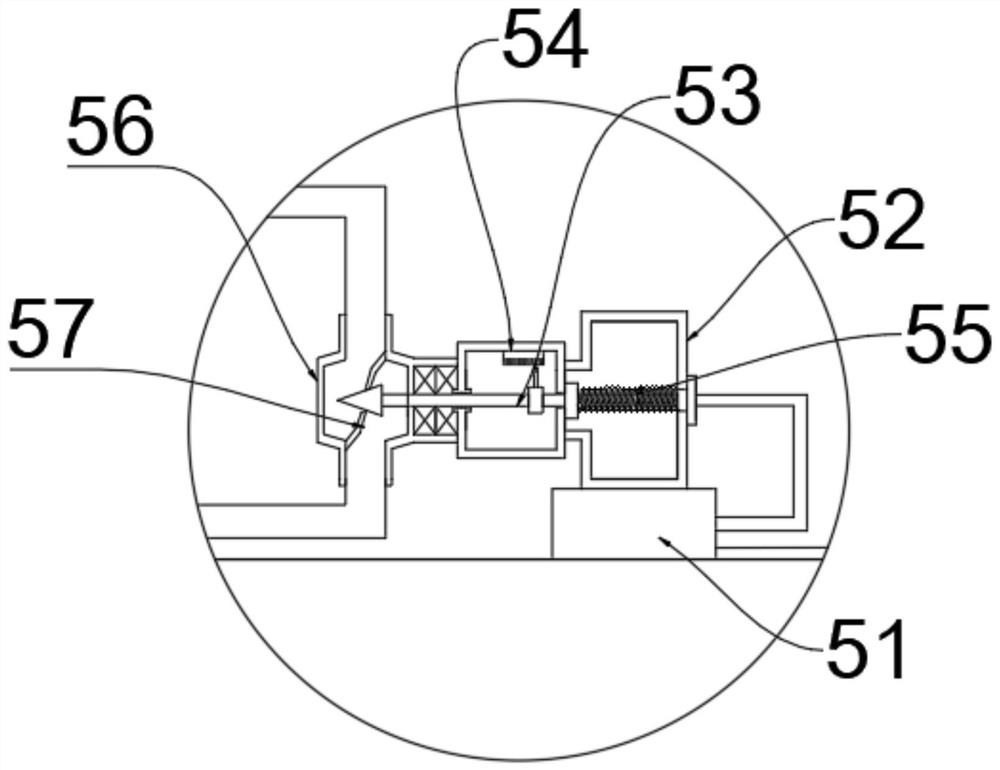

[0030] refer to Figure 1-5 , an ultrasonic cleaning device, comprising a body 1, a cleaning device 2 and a control device 3, an ultrasonic cleaning device 8 is arranged on the side of the cleaning device 2, and a motor 11 and a rotating shaft 12 are arranged above the cleaning device 2, and the rotating shaft 12 is connected to the The output ends of the motor 11 are connected, and the side of the rotating shaft 12 is connected with several roller brushes 13, and the side of the rotating shaft 12 is slidingly connected with several nozzles 14, and the nozzles 14 are connected with a water control device arranged on the top of the fuselage 1 through water pipes 5, and the side of the water control device 5 is connected to the water tank 10 through a water pipe, the cleaning device 2 includes a cleaning table 21 and a return cavity 22 arranged inside the cleaning table 21, and the inside of the cleaning table 21 is provided with several through holes, and the through holes are c...

Embodiment 2

[0038] refer to Figure 6 , an ultrasonic cleaning device, compared with Embodiment 1 in this embodiment, the drying device 7 includes a drying chamber 71 and a filter screen 72 arranged inside the drying chamber 71, and a heating wire 73 is arranged below the filter screen 72 , Two blowers 74 are arranged above the drying chamber 71 .

[0039] Working principle: when in use, the drying device 7 is provided to facilitate drying when the ultrasonic cleaning is completed, so as to ensure that the parts are in a dry state, which is beneficial to the preservation of the parts, and the filter 72 is provided to ensure the cleanness of the air during use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com