Agricultural planting greenhouse capable of automatically removing snow

A technology for greenhouses and agriculture, applied in the field of agricultural greenhouses, can solve the problems of slowing down the growth rate of crops, affecting light irradiation, crop damage, etc., and improving the efficiency of snow removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

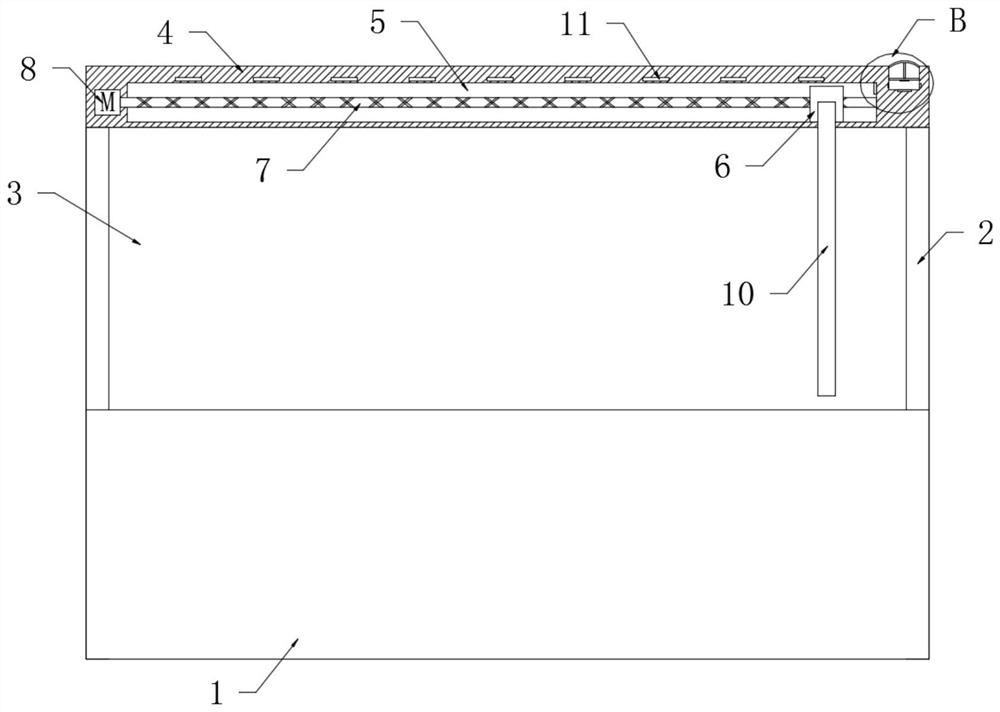

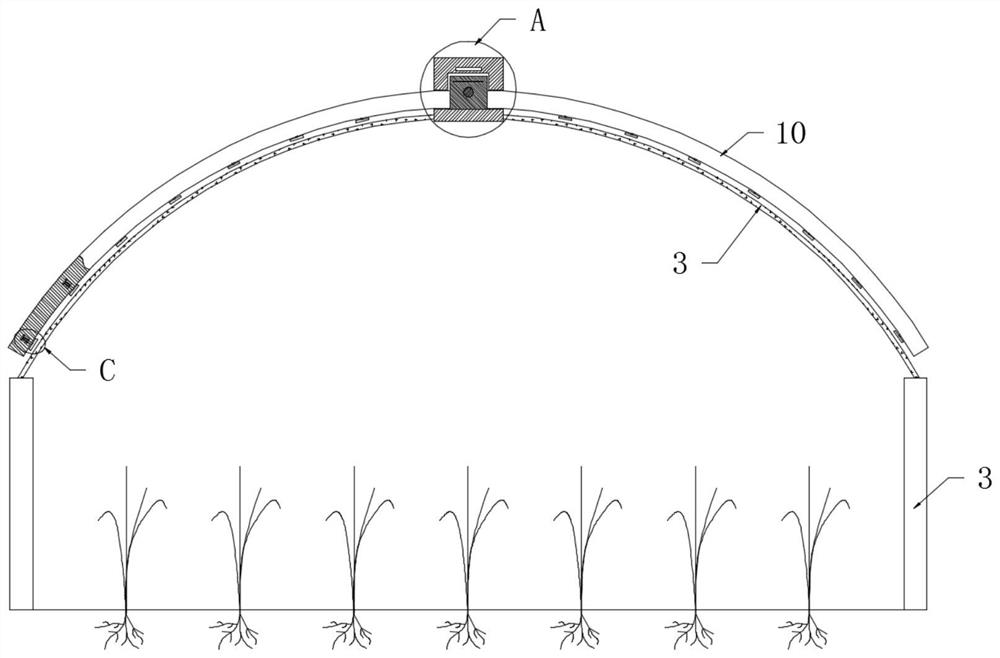

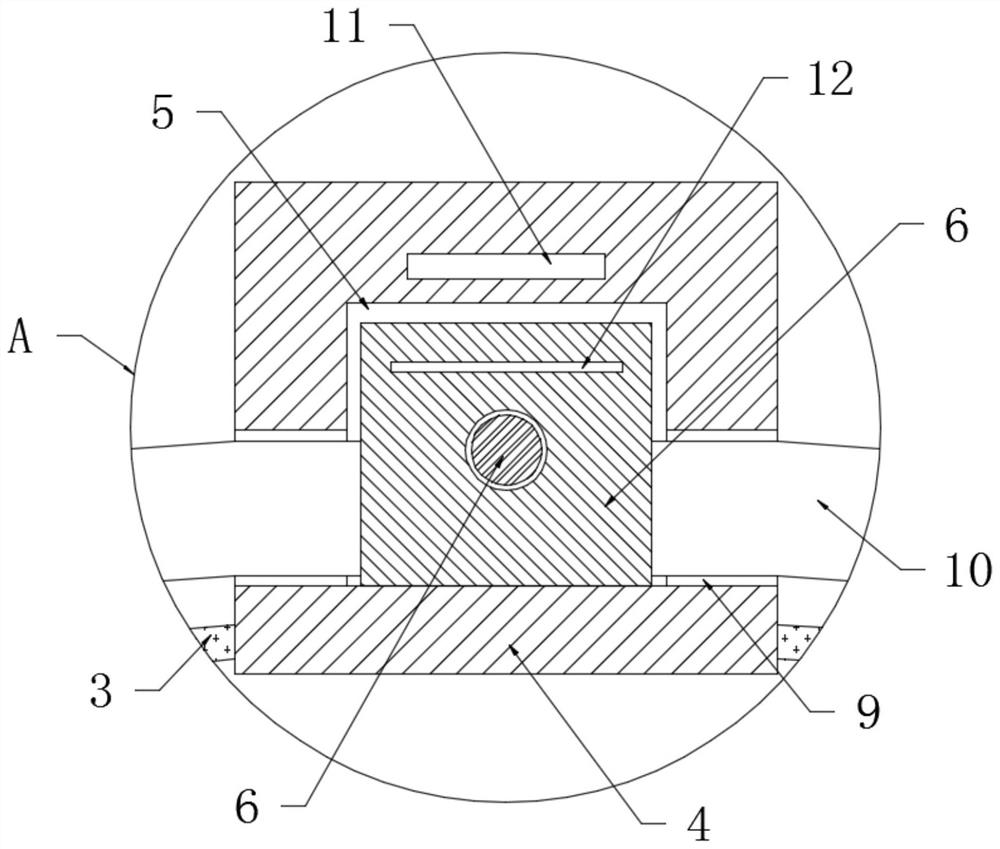

[0022] refer to Figure 1-5 , an agricultural planting greenhouse for automatic snow removal, including a greenhouse body composed of a support plate 1 fixedly connected to the ground and a greenhouse skeleton 2, the top of the greenhouse skeleton 2 is fixedly connected with a horizontal fixed beam 4, the greenhouse skeleton 2 and the fixed beam 4 A plastic film 3 in the shape of a semicircle is connected together, and a sliding chamber 5 is provided in the fixed beam 4, and a reciprocating screw rod 7 is connected to the wall at both ends of the sliding chamber 5, and a screw slider is slidably connected to the sliding chamber 5 6. The screw slider 6 and the reciprocating screw 7 are threadedly connected. One end of the reciprocating screw 7 is connected with a motor 8. The motor 8 is fixed in the fixed beam 4 and electrically connected with the external circuit. The outer walls of both sides of the fixed beam 4 Each is provided with a chute 9, and the two chute 9 are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com