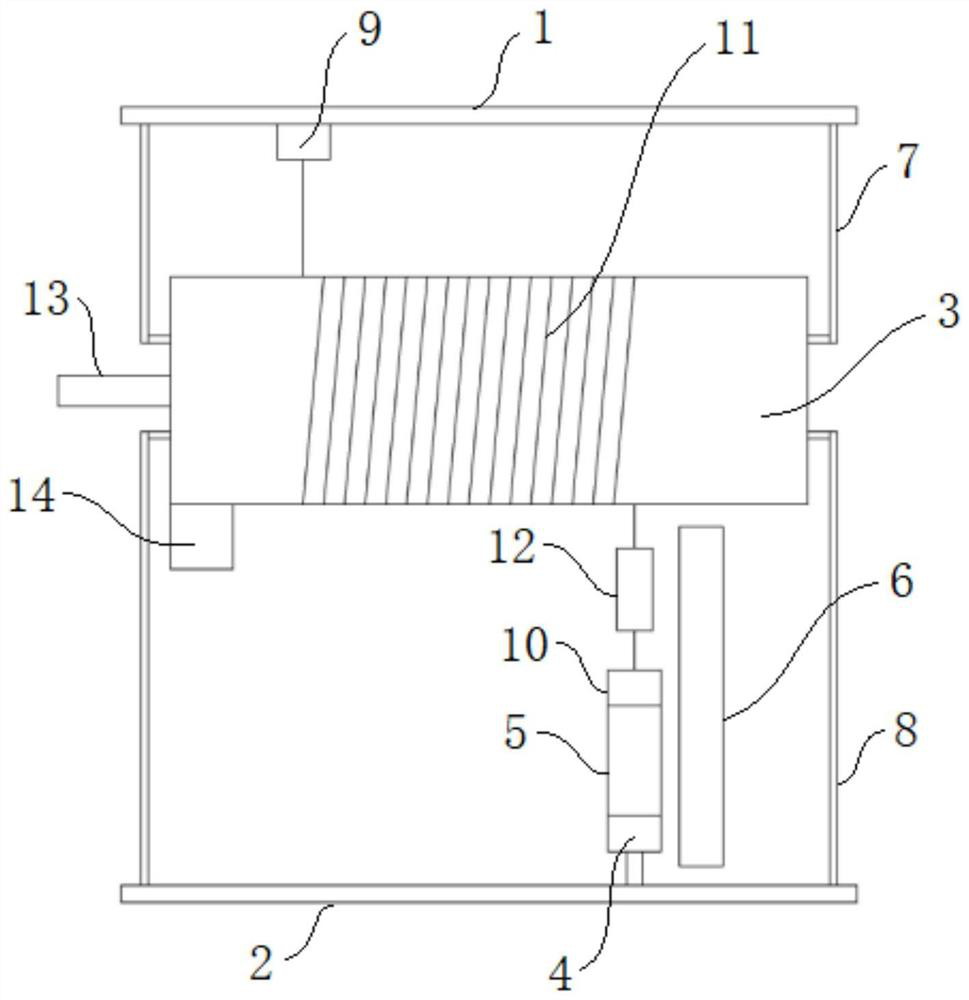

Yarn thermal shrinkage rate testing device and testing method

A technology of thermal shrinkage and testing device, applied in electromagnetic measuring device, material thermal expansion coefficient, electric/magnetic solid deformation measurement, etc., can solve the problems of long thermal shrinkage testing time and low accuracy, and achieve high design reference value , easy to operate, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The tension adjustment structure in the yarn thermal shrinkage test device was adjusted to make the tension value 2.5cN, and the initial length of the para-aramid yarn was measured to be 1.000m by an automatic length measuring instrument.

[0052] Then the whole test device was placed in a high temperature box, and heated to 60°C for 30min.

[0053] Finally, the change value of the resistance strain gauge was read, and the thermal shrinkage of the para-aramid yarn at this temperature was obtained by calculation as 99.91%.

[0054] It can also be seen from Example 1 that the accurate thermal shrinkage rate of the para-aramid yarn can be quickly obtained by using this test device, and the test accuracy can reach 1 / 10,000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com