A double-layer double-door electric flap valve

A flap valve, electric technology, applied in the direction of lifting valve, valve details, valve device, etc., can solve the problems of inconvenient cleaning, easy accumulation of materials to block channels, and blocking of suction materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

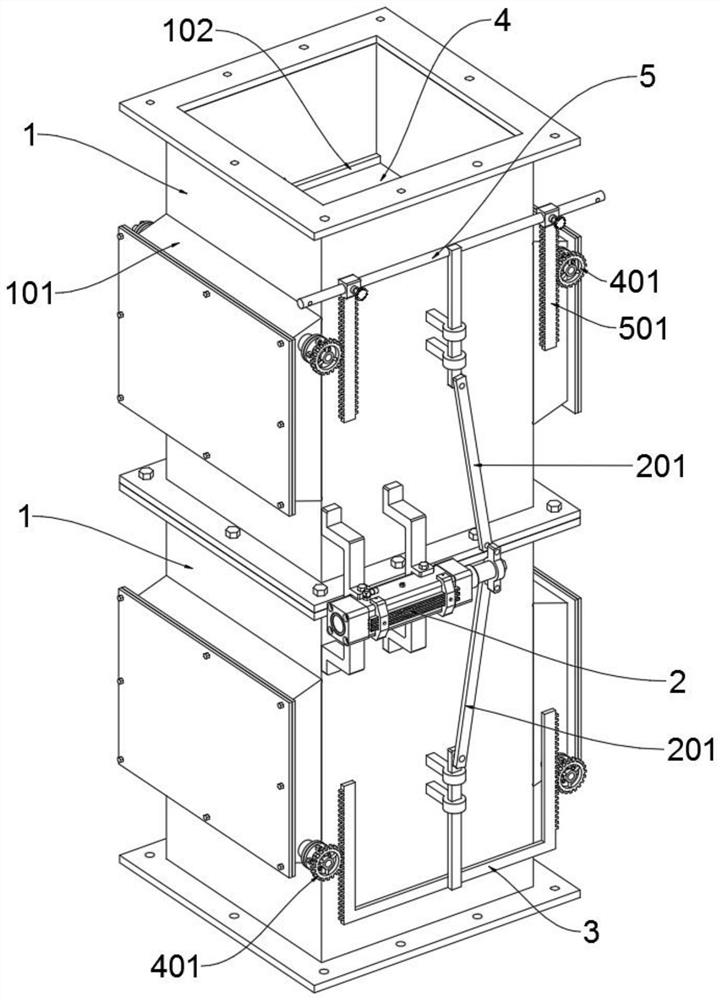

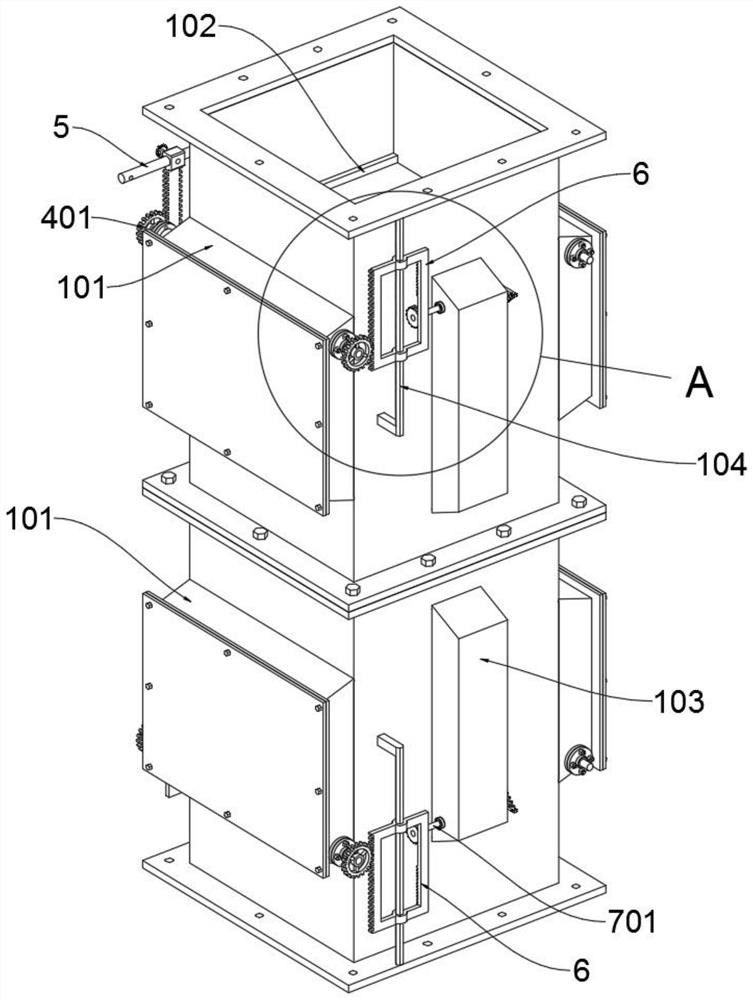

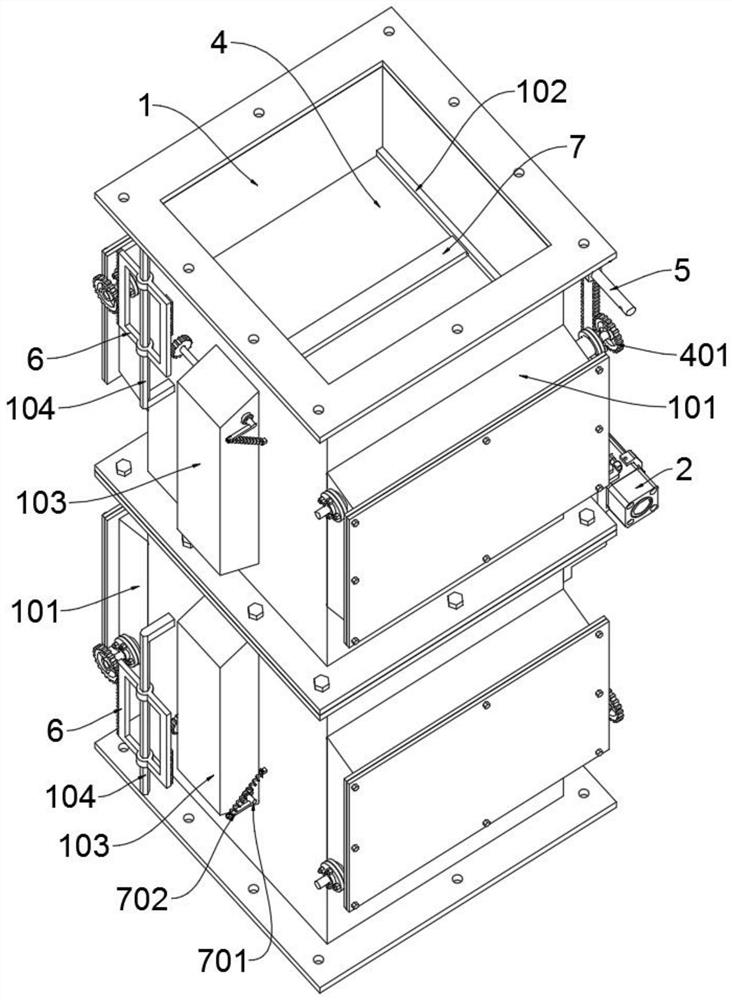

[0039] see Figures 1 to 11 , a double-layer double-door electric flap valve according to a preferred embodiment of the present invention includes a square tube housing 1, and the square tube housing 1 includes a square mounting cover 101, abutting rod 102, a long rectangular cover 103 and a hexagonal positioning cover The shaft 104, the upper and lower prescription tube shells 1 are symmetrically locked together to form the main body support frame of the flap valve, and the left and right side walls of the two prescription tube shells 1 are symmetrically convexly welded with two square installation covers 101 , a cover plate is locked and blocked on the outer openings of the two square installation covers 101 . The middle positions of the rear side walls of the two prescription tube shells 1 are both convexly welded with a long rectangular cover 103, and a transverse beam plate 7 is installed inside the two long rectangular covers 103, and two squares are installed. Inside t...

Embodiment 2

[0042] Further, the cross beam plate 7 includes a rotating shaft 701 and a swing plate 702, a rotating shaft 701 is welded and fixed at the rear ends of the two cross beam plates 7, and the left ends of the two rotating shafts 701 are both sheathed with a pinion, and the two A swinging plate 702 is welded to the right end of the rotating shaft 701, and two tension springs are rotatably supported between the two swinging plates 702 and the rear side walls of the two prescription tube shells 1. The two cross-beam plates 7 are pulled and kept in a horizontally supported abutting state, and when the flip valve is in the open state, the two cross-beam plates 7 can be rotated and placed in a sagging state, and the two prescription tube shells 1 The middle channel is completely vacated to avoid the blocking and blocking of the suctioned materials in the channel caused by the long-term standing of the two transverse beam plates 7 in the transverse support state, so that the materials a...

Embodiment 3

[0046] The working principle of the double-layer double-door electric flap valve according to a preferred embodiment of the present invention is as follows: when switching the open and closed states of the two sets of flaps 4, the initial state of the upper two flaps 4 should be rotated to The drooping position; the connecting rod 201, the T-shaped driving frame 5, the mountain-shaped driving frame 3 and the piston rod of the oil cylinder 2 together form a double-link slider mechanism, through which the piston rod of the oil cylinder 2 can slide forward and backward to push the T The shaped drive frame 5 and the zigzag drive frame 3 slide toward each other, and synchronously control the flipping, opening and closing of the upper and lower two sets of flaps 4. The two drive rods 501 can slide toward each other along the horizontal support shaft at the top of the T-shaped drive frame 5. The outer sides of the two driven gears 401 make the two rows of tooth slots on the inner side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com