Continuous automatic thermal shrinkage bag wrapping system

A heat-shrinkable bag and wrapping technology, which is applied in the direction of packaging, wrapping paper, wrapping paper shrinkage, etc., can solve the problems of injury, low production efficiency, time-consuming and labor-intensive problems, and achieve the effects of improving stability, saving time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

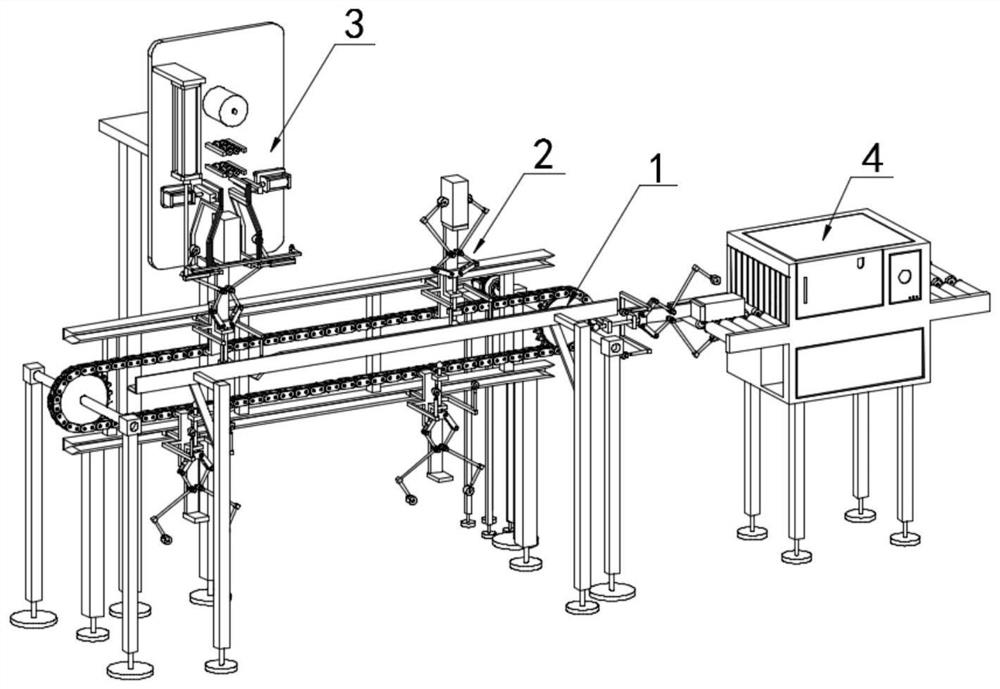

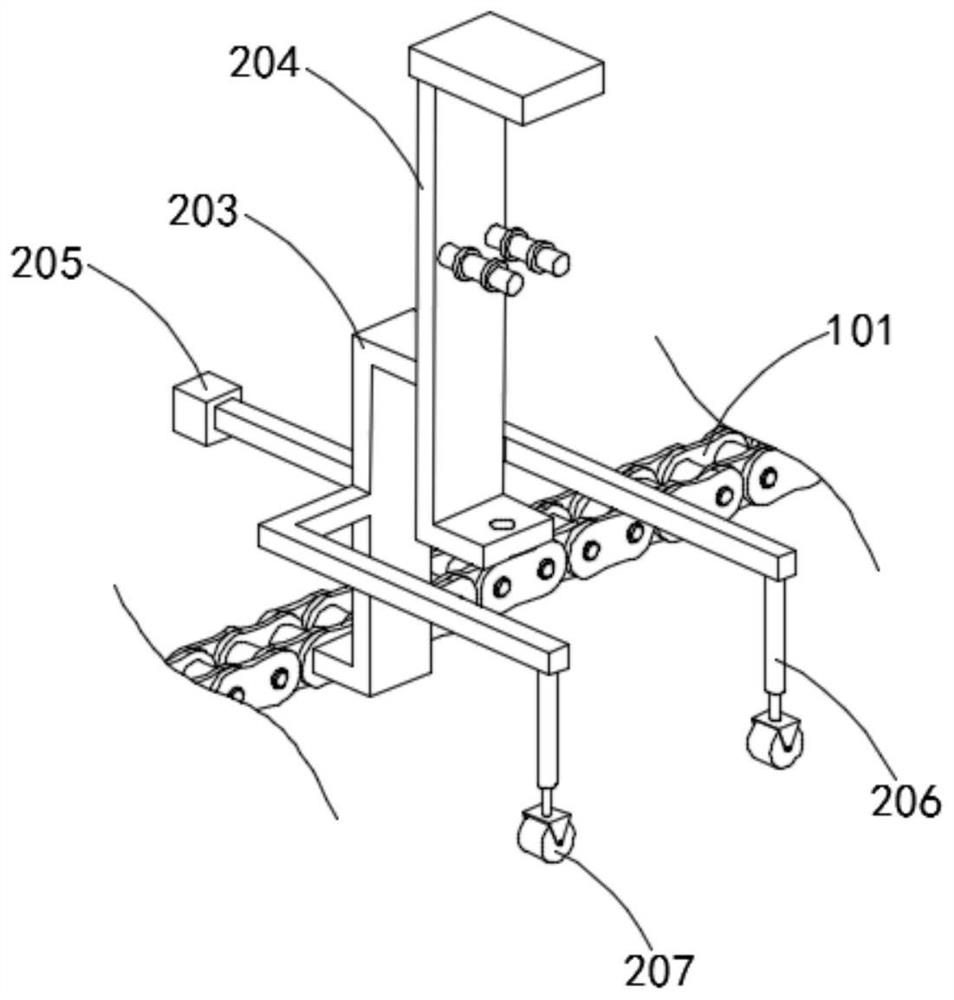

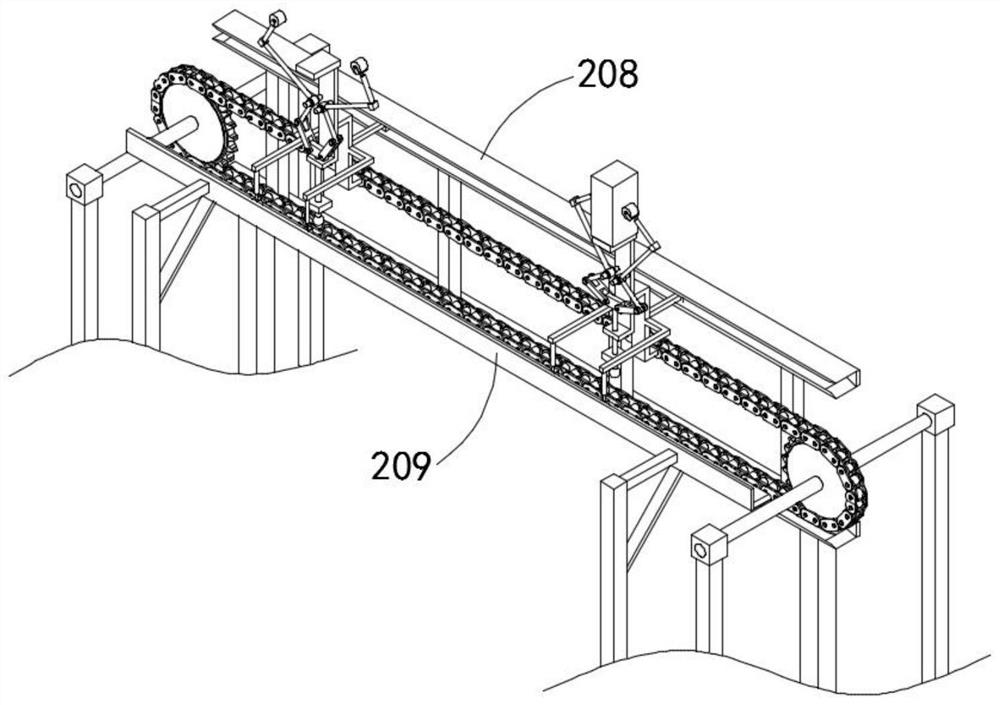

[0035] like Figure 1 to Figure 12 As shown, a continuous automatic wrapping system for shrinkable bags includes a rotating device 1, the rotating device 1 includes a rotating chain 101, and a plurality of carrying devices 2 are fixed on the rotating chain 101, and the carrying device 2 includes A support assembly 201 and a clamp assembly 202, the support assembly 201 is used to carry and support the lithium battery pack that moves with the swivel device 1, and the clamp assembly 202 is used to clamp the heat shrink bag wrapped outside the lithium battery pack, The moving path of the carrying device 2 is also provided with a matching wrapping device 3 and a heat shrinking device 4. The wrapping device 3 includes an adsorption component 301 and a cutting component 302. The adsorption component 301 is used for the heat shrinkable bag. The two sides of the two sides are adsorbed and expanded and buckled on the lithium battery pack. The cutting assembly 302 is used to cut the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com