a beam structure

A crossbeam and crossbeam assembly technology, which is applied in the field of vehicle crossbeam structure and crossbeam structure, can solve problems such as inadequacy and large resistance of the crossbeam structure, and achieve the effects of reducing processing difficulty, improving maintainability, and enhancing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions in this embodiment will be clearly and completely described below in conjunction with the accompanying drawings in this embodiment. However, this should not be construed as limiting the present invention to specific embodiments, but only for explanation and understanding:

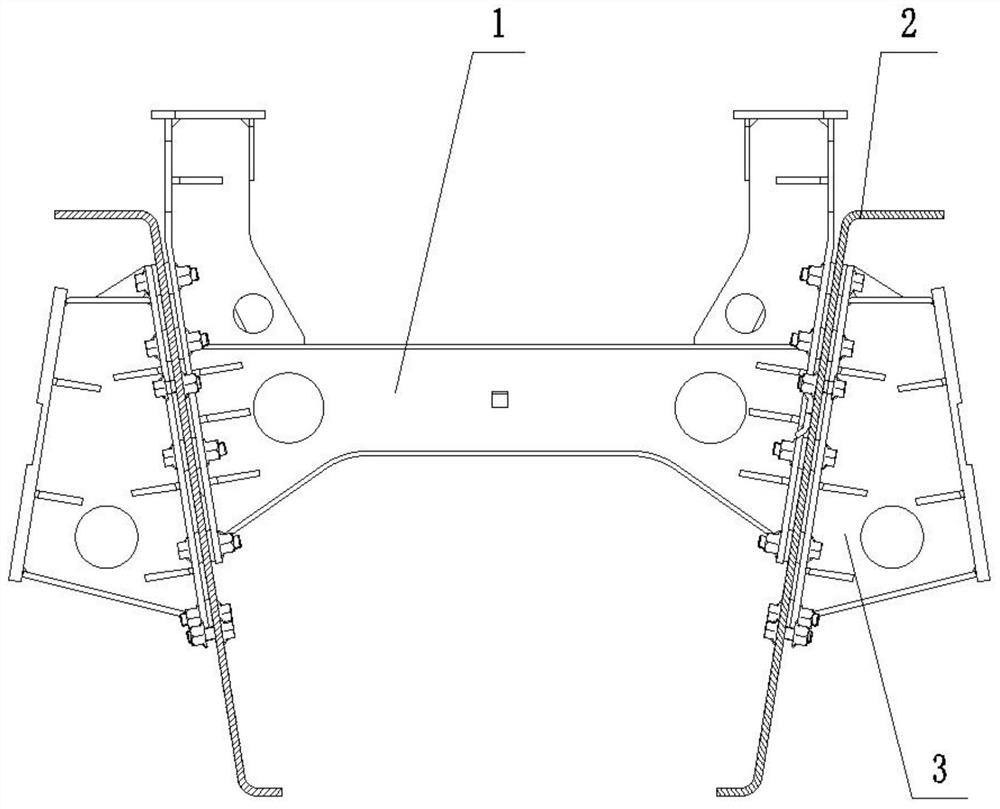

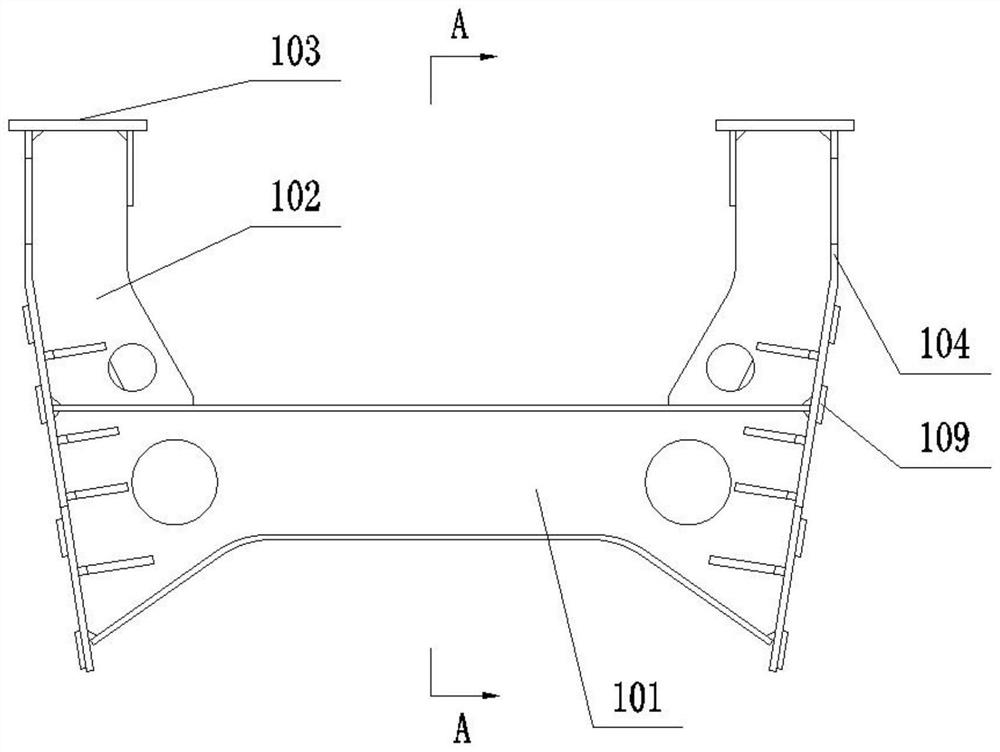

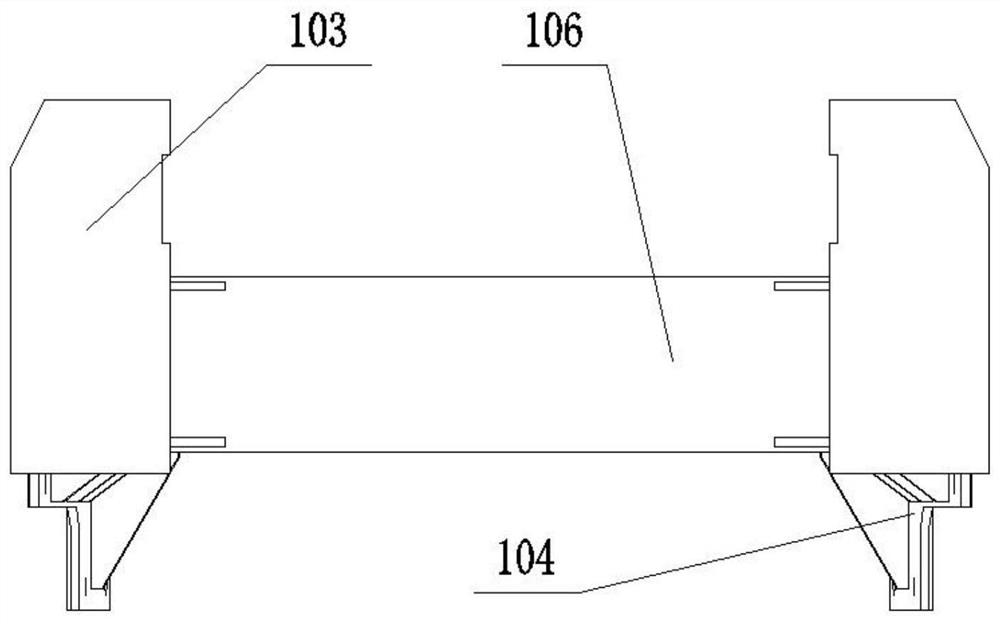

[0032] Such as Figure 1 to Figure 5 As shown, this embodiment provides a beam structure, including a beam assembly 1 , a longitudinal beam 2 and a bracket assembly 3 .

[0033] A longitudinal beam 2, a crossbeam assembly 1 is arranged between the two longitudinal beams 2, and a bracket assembly 3 is provided on the side of the longitudinal beam 2 away from the crossbeam assembly 1; the longitudinal beam 2, the The beam assembly 1 is detachably connected to the bracket assembly 3 .

[0034] The existing beam adopts a welded structure, and the thickness of the longitudinal beam 2 is relatively thin. When the jack directly acts on the longitudinal beam 2 or the beam, the longit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com