Solid wood part machining production line

A part processing and production line technology, which is applied in the field of solid wood part processing production line, can solve the problems that cannot be applied to the positioning of different cross-section solid wood parts or continuous feeding processing, and achieve the effect of preventing failure and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

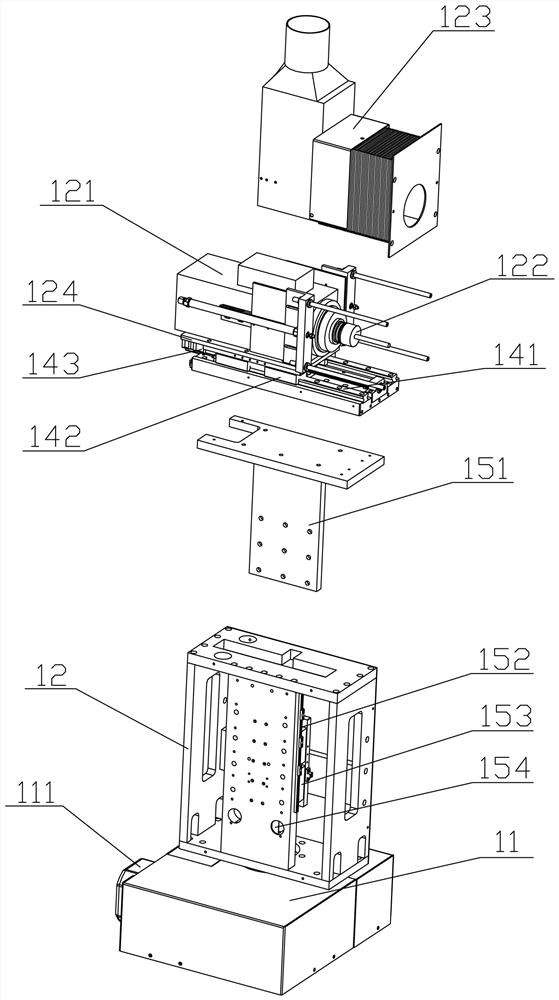

[0040] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. In order to provide a comprehensive understanding of the present invention, many details are described below, but it will be apparent to those skilled in the art that the present invention can be practiced without these details.

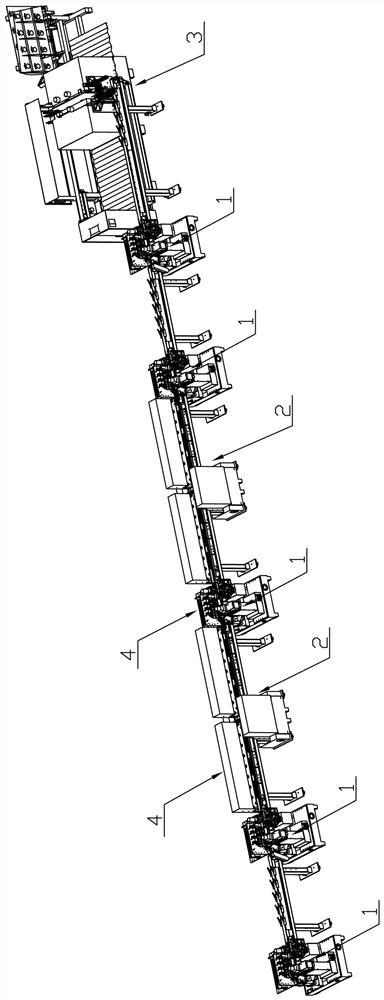

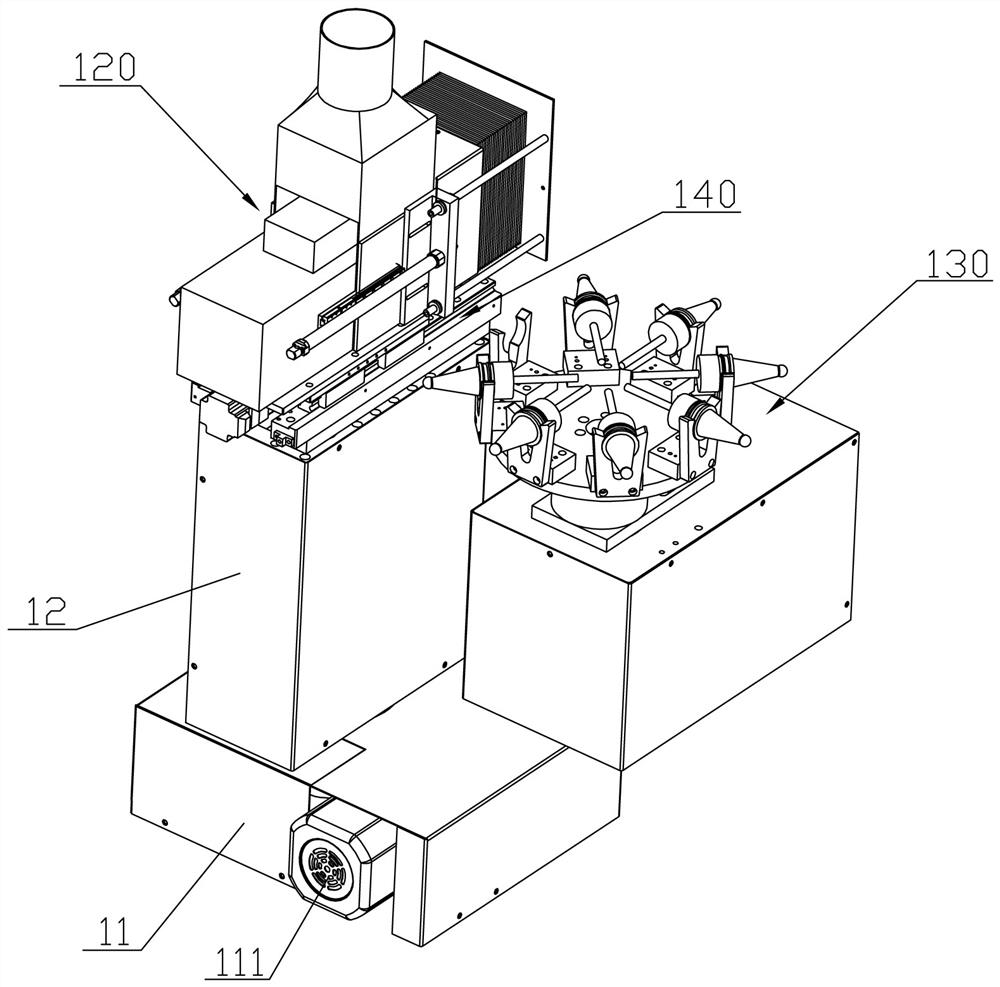

[0041] A production line for processing solid wood parts, including a processing module and a transition conveying module. The processing module includes at least one module of a drilling machine module, a slot milling machine module, and a double-end tenon milling machine module, and is arranged and combined arbitrarily on the same line. Both the drilling machine module and the milling machine module include a transition delivery module. refer to figure 1 , the solid wood parts processing production line shown in this embodiment includes five continuously arranged drilling machine modules 1 and a double-end tenon milling machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com