Full-automatic oil-water separation treatment device for cooling box of machine tool

A technology of oil-water separation and treatment device, which is applied in the field of machine tools to avoid hidden dangers of electricity consumption, improve work efficiency and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited to the following embodiments.

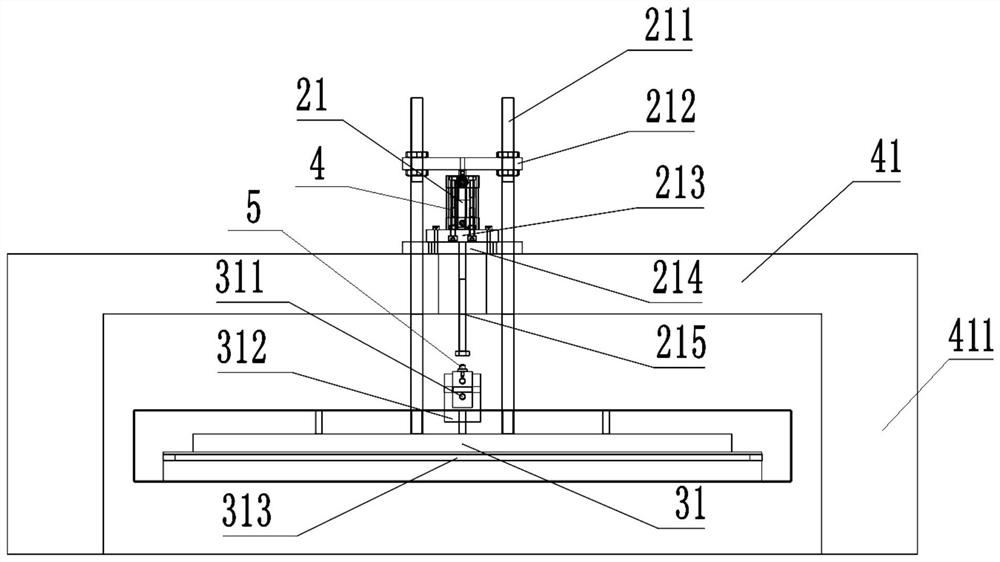

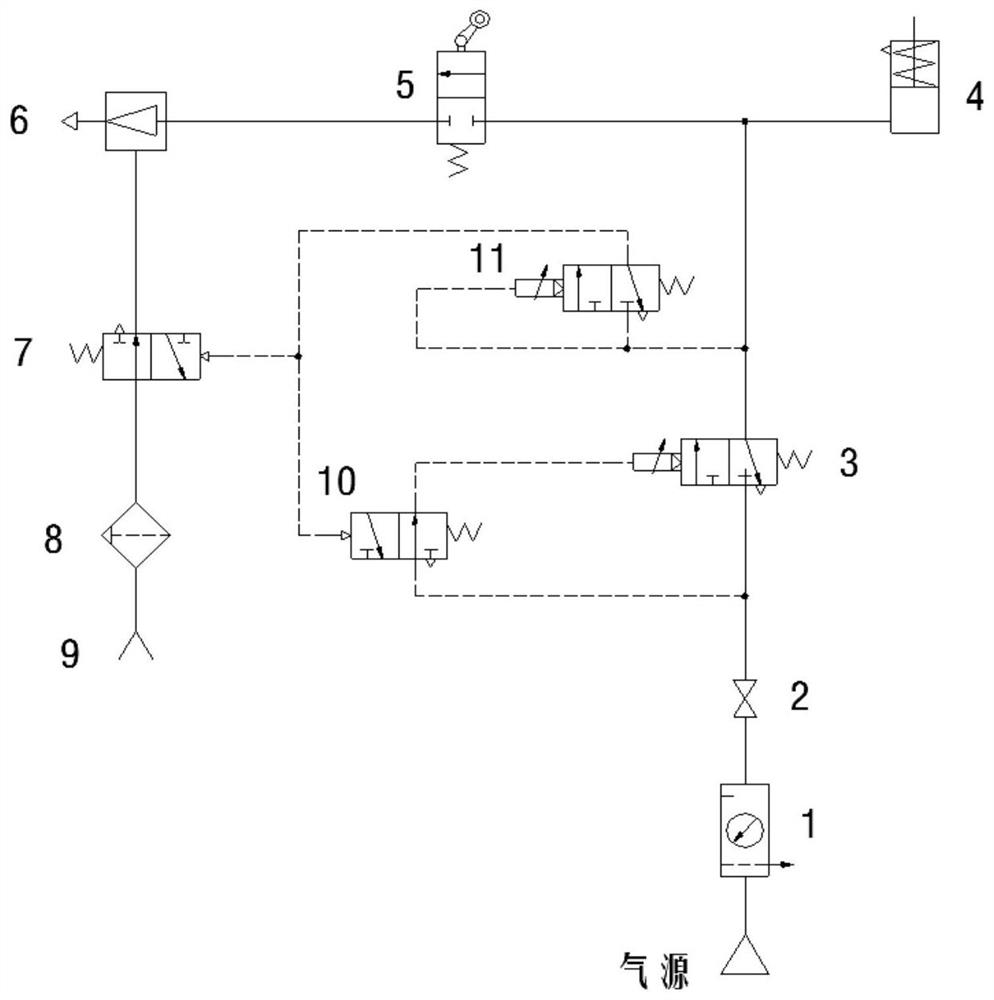

[0028] The fully automatic oil-water separation treatment device for the machine tool cooling box of the present invention can realize fully automatic pneumatic control, and can efficiently perform oil-water separation treatment, including frame parts, lifting parts, adsorption parts and a pneumatic control system.

[0029] The frame part is the basis of the whole device. The lifting parts, adsorption parts and some components and parts of the pneumatic control system are fixed on the frame part and float on the cooling liquid surface in the cooling box of the machine tool, which can meet the The relative position of the oil-absorbing cotton and the coolant level remains unchanged.

[0030] Specifically, see figure 1 , the frame part 41 mainly incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com