Spinal surgery auxiliary device

A technology of surgery and auxiliary equipment, applied in medical science, prostheses, joint implants, etc., can solve the problems of complex motion structure, lower bone crushing efficiency, time-consuming and labor-intensive bone crushing, etc., achieve simple motion structure, improve crushing The effect of high bone efficiency and bone crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

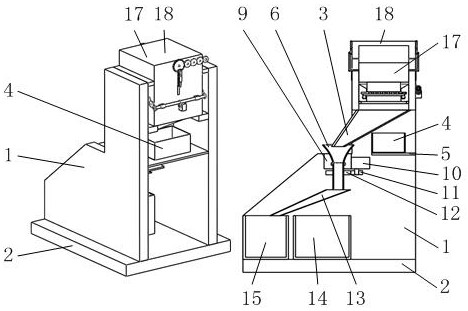

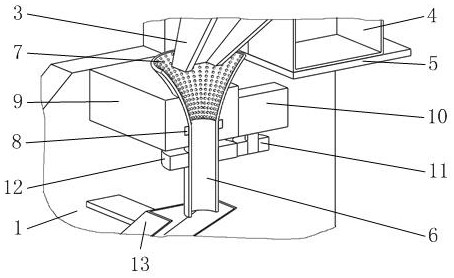

[0043] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

[0044] Such as figure 1 , 2 As shown, it includes a support plate 1, a base 2, a funnel A3, a stab-removing rotator 6, a funnel B13, an electric drive module A10, and a bone crushing mechanism 17, wherein figure 1 As shown, the bone crushing mechanism 17 is installed on the base 2 through two symmetrically distributed support plates 1, and the crushed bones coming out of the bone crushing mechanism 17 are screened by the funnel A3 installed below to carry out the separation of bone crushing particles and bone crushing powder. Separation and collection: the broken bone particles screened by the funnel A3 enter the trumpet-shaped stab-removing gyratory 6 driven by the electric dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com