Tea stir-frying device with good thermal insulation function

A stir-frying and functional technology, which is applied in the direction of tea processing before extraction, can solve the problems of wasting energy and reducing the efficiency of tea stirring, and achieves the effect of evenly stirring and increasing the stirring efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

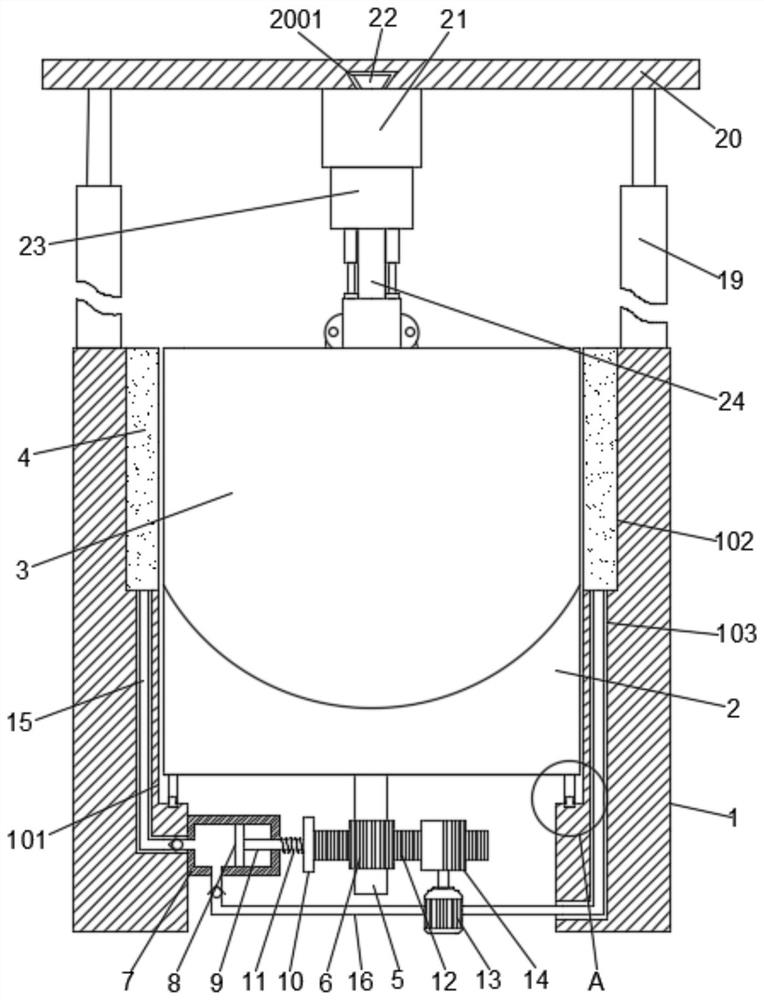

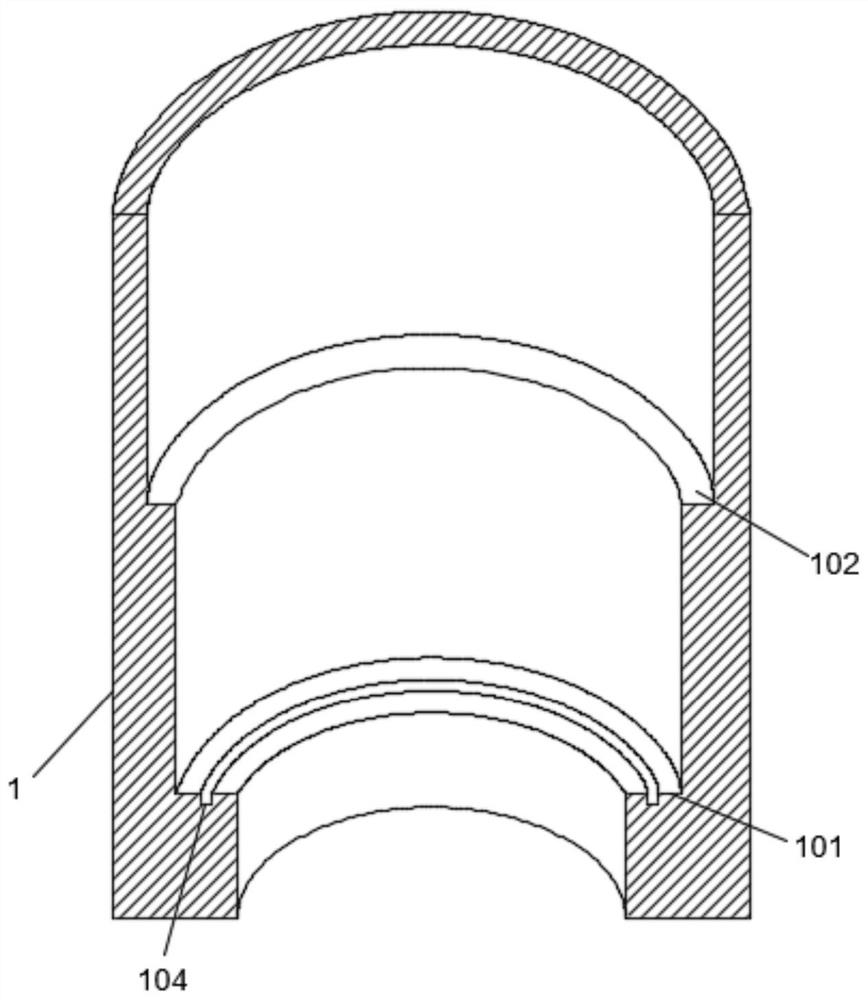

[0034] like Figure 1-6A tea stir-frying device with good heat preservation function, including an installation cylinder 1, the installation cylinder 1 is a main structure with a hollow interior, and an installation groove 101 is provided inside the installation cylinder 1, and the installation groove 101 A heating table 2 is rotatably installed, the top of the heating table 2 is set in an arc shape, a stir-fry box 3 is fixedly installed above the heating table 2, and the bottom of the stir-fry box 3 is arranged corresponding to the heating table 2, and the installation The top of the groove 101 is provided with a fixing groove 102, the interior of the fixing groove 102 is fixedly installed with a heat preservation cylinder 4, the cross section of the heat preservation cylinder 4 is in the shape of a ring, and there is a gap between the inner wall of the heat preservation cylinder 4 and the outer wall of the frying box 3 , the heat preservation cylinder 4 is filled with hot wa...

Embodiment 2

[0044] On the basis of Example 1, as Figure 7-10 shown; the stir-frying device includes a third motor 23, a transmission shaft 24, an upper sleeve 27, a first hinged support 28, an active rocker 29, a lower sleeve 30, a second hinged support 31, a driven swing The rod 32 and the stir-frying blade 33, the third motor 23 is fixedly installed on the bottom of the installation table 21, the output shaft of the third motor 23 is fixedly installed with a transmission shaft 24, the transmission shaft 24 is set in a prismatic shape, the The upper end of the transmission shaft 24 is sleeved with an upper shaft sleeve 27, the upper shaft sleeve 27 is arranged corresponding to the transmission shaft 24, and four sets of first hinged supports 28 are fixedly installed on the peripheral side of the upper shaft sleeve 27. The first hinged The support 28 is hingedly connected to one end of the active rocker 29, the lower end of the transmission shaft 24 is fixedly mounted with a lower bushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com