Micro-vibration integrated simulation analysis method of optical remote sensing camera

A technology of optical remote sensing and simulation analysis, applied in the field of integrated simulation of optical remote sensing cameras, can solve the problems of optical-mechanical integration model grids and nodes, low calculation efficiency, etc., achieve strong guiding significance, accurate simulation analysis results, and calculation efficiency Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

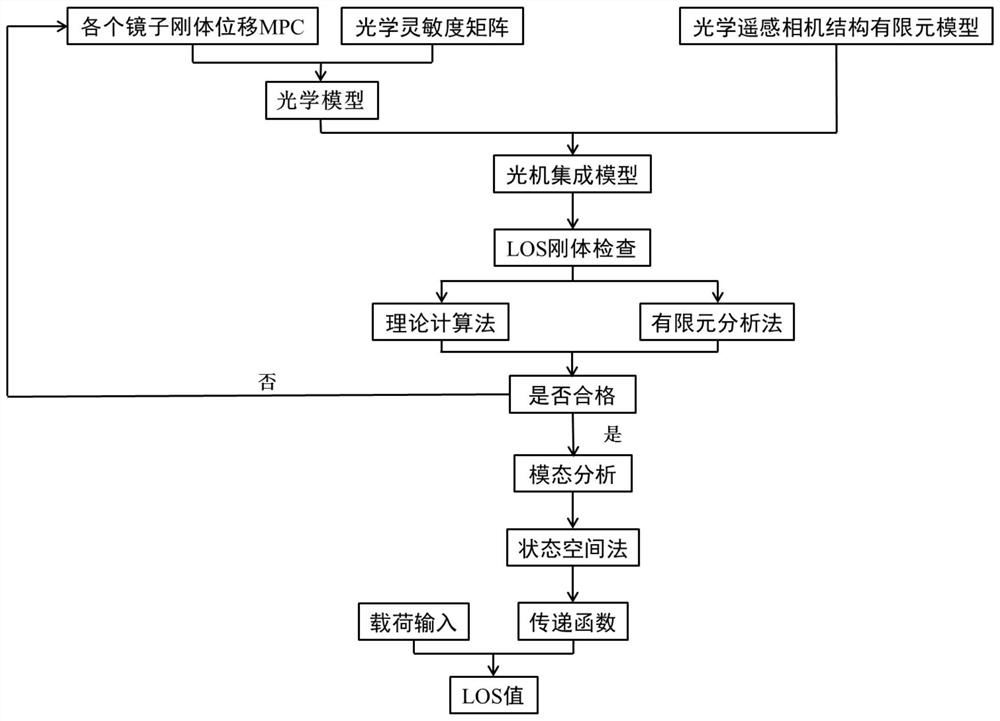

[0055] Such as figure 1 As shown, a micro-vibration integration simulation analysis method for an optical remote sensing camera, the specific process is as follows:

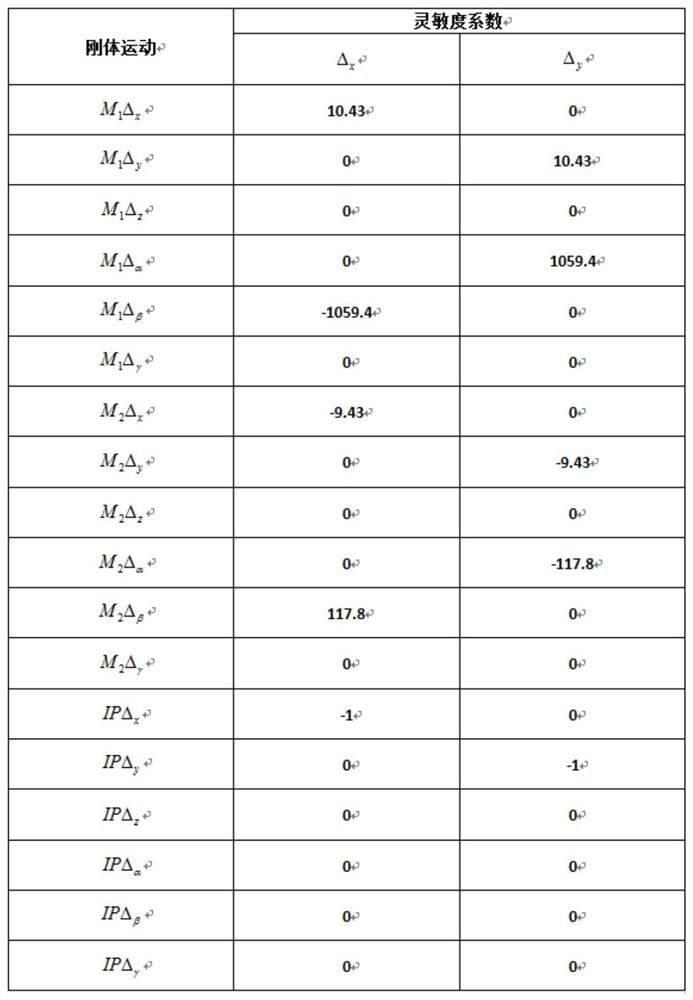

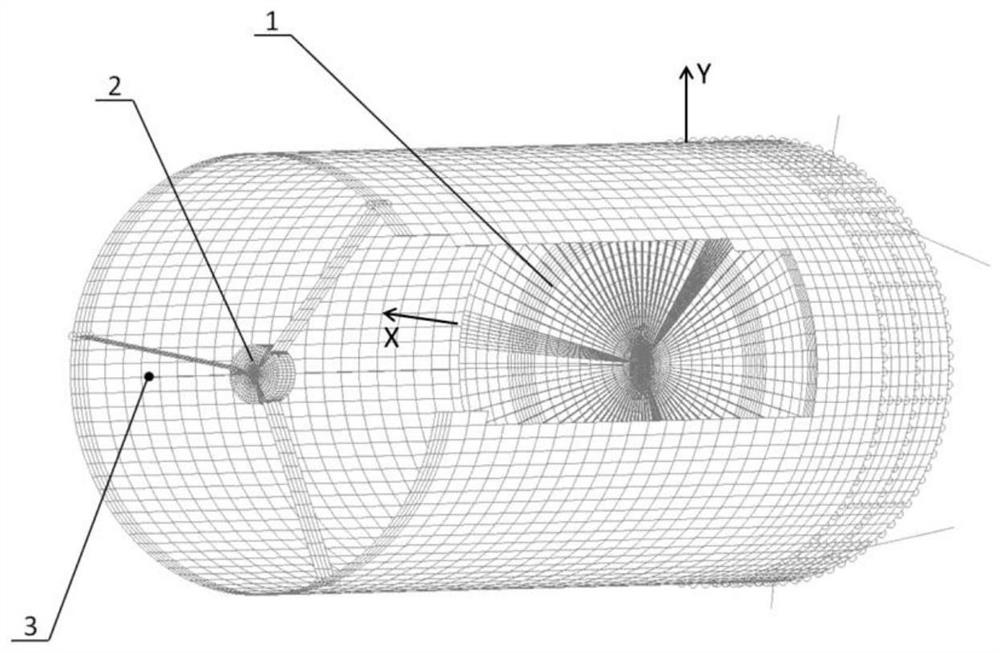

[0056] 1. Establish the finite element model of the optical remote sensing camera structure in MSC.Patran, and use the information such as the radius of curvature of each mirror, the property of the mirror surface material, and the number of the analysis coordinate system to locate the mirror surface of each mirror in the optical software SigFit, and get each mirror by fitting. The rigid body displacement MPC of the mirror is further utilized figure 2 Create an optical model based on the optical sensitivity matrix in , and integrate the optical model into the finite element model in the form of a bdf file to obtain the optical-mechanical integration model of the optical remote sensing camera, see image 3 ;

[0057] 2. Use the theoretical calculation method or the finite element analysis method to perform LOS ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com