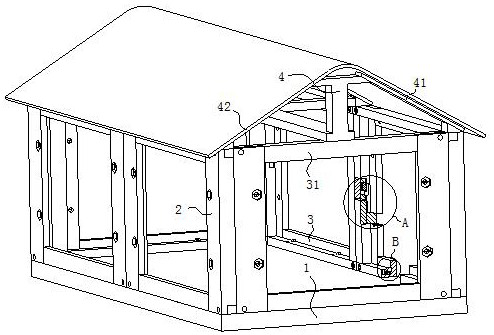

Integrated prefabricated steel structure building

A steel structure and assembly technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of low installation efficiency of wall panels and the inability to improve the need for multiple measurements of verticality for temporary support of wall panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

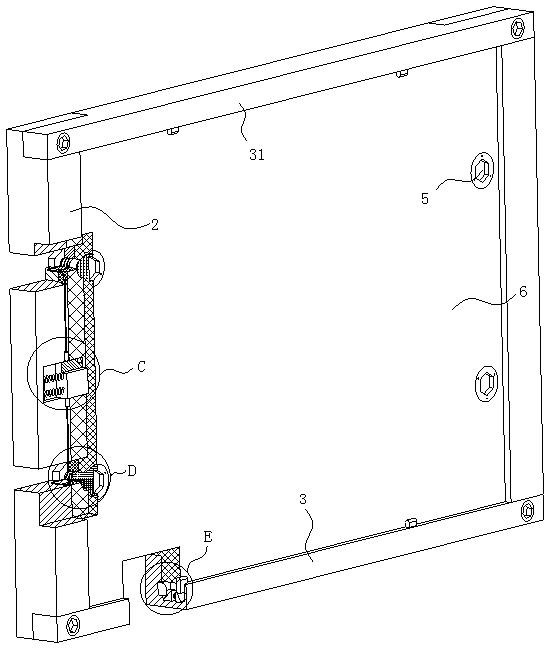

Method used

Image

Examples

Embodiment approach

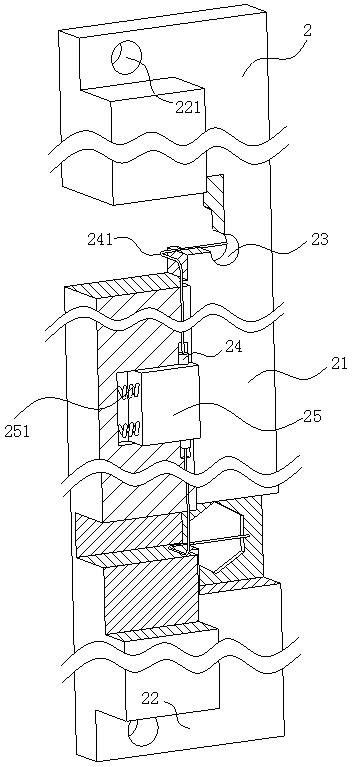

[0036] As an embodiment of the present invention, the pushing block 36 includes a movable block 1 361, a movable block 2 362 and a spring 2 363; the spring 2 363 is located in the middle of the movable block 361 and the movable block 2 362; the spring 2 The two ends of 363 are respectively fixedly connected on the opposite sides of movable block one 361 and movable block two 362; Contact; the cross section of the second movable block 362 is a right triangle, and the slope on the second movable block 362 is in contact with the lower end of the second column 34 .

[0037] During work, after the wallboard 6 contacts and extrudes the extension column one 33, the extension column one 33 moves in the cavity, and at the same time, when the extension column one 33 moves, the extension column one 33 and the movable block one 361 Contact and push the movable block one 361 to move toward the direction of the second column 34. After the movable block one 361 moves, the movable block two 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com