Fabricated type drainage ditch and construction method thereof

A drainage ditch and prefabricated technology, applied to drainage structures, chemical instruments and methods, water supply devices, etc., can solve the problems that two components cannot be assembled horizontally, the cover plate is uneven, and the drainage weir is silted and blocked.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

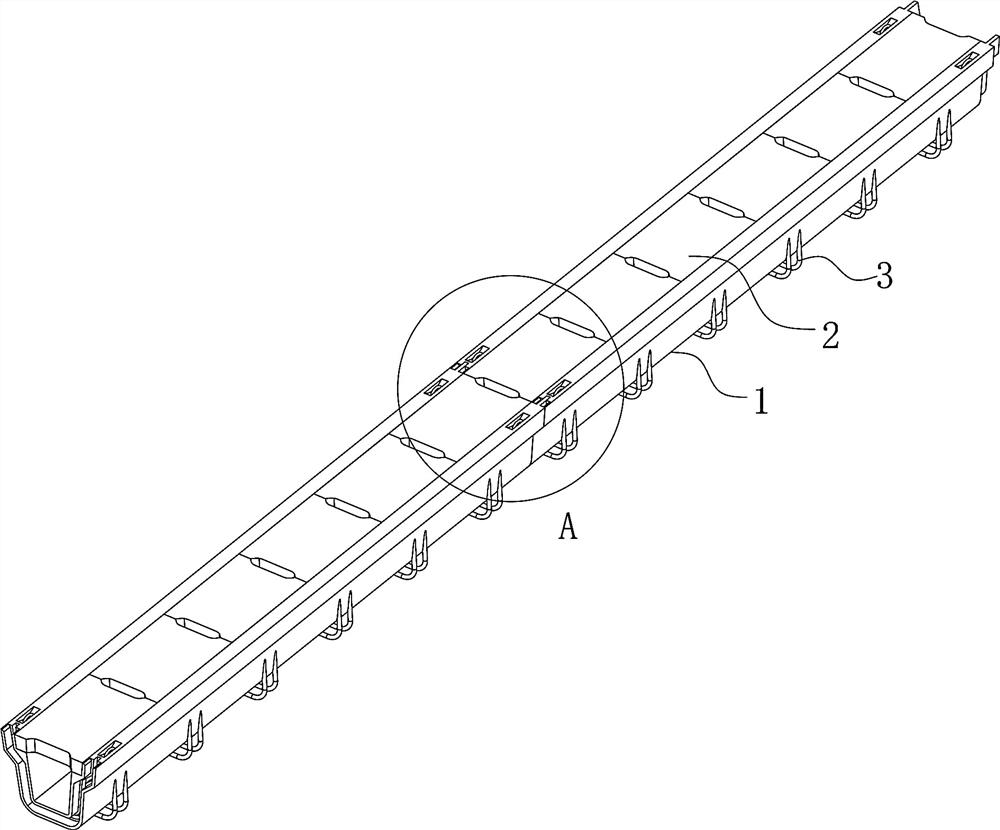

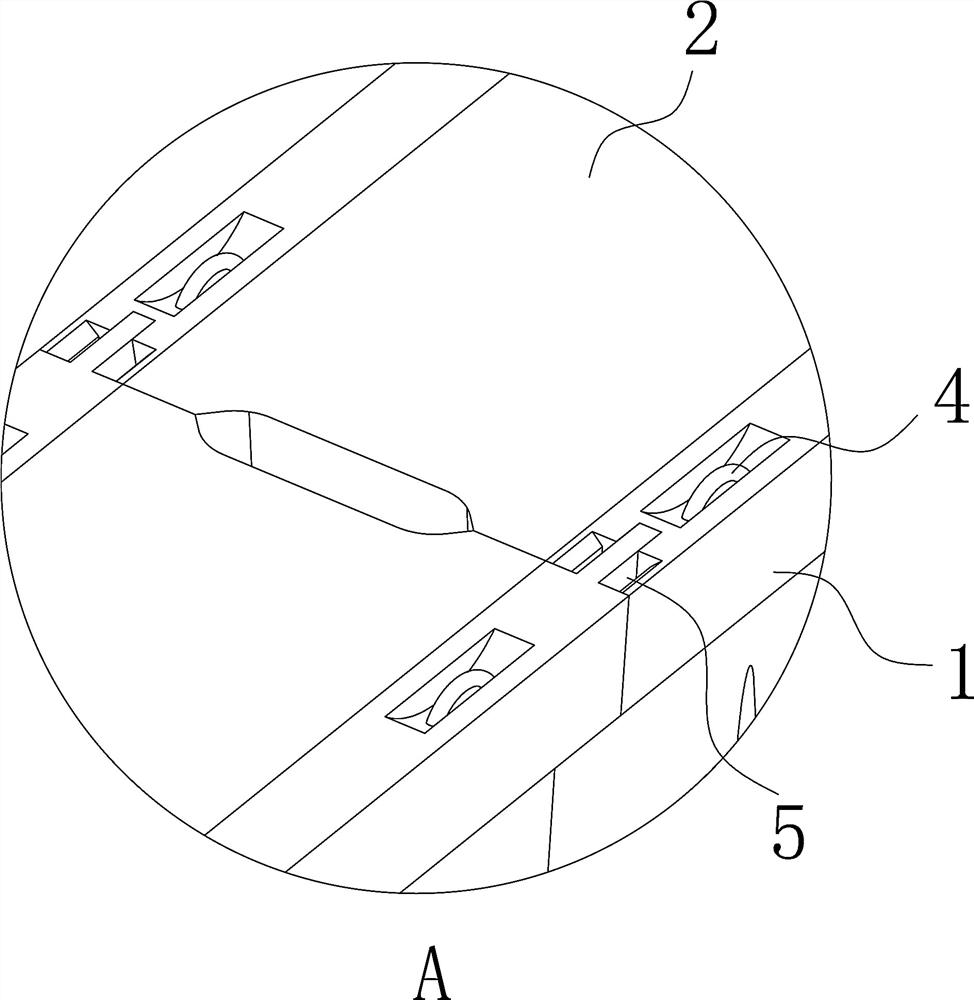

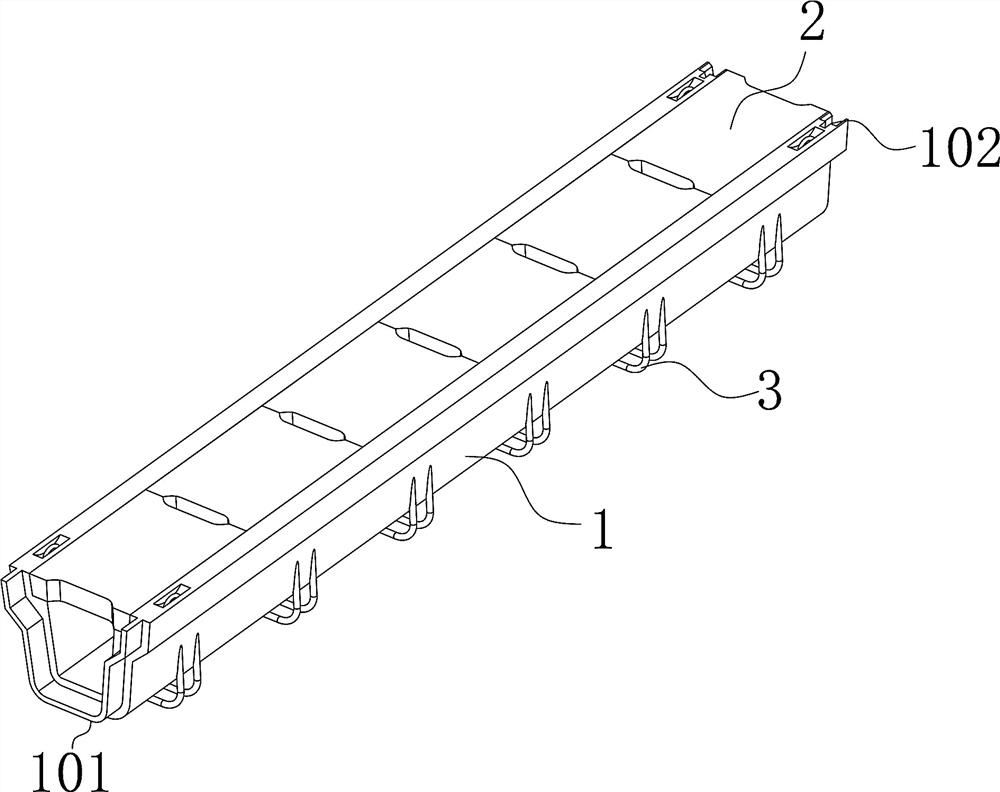

[0045] Such as Figure 1~12As shown, an assembled drainage ditch includes a drainage ditch 1, one end of the drainage ditch 1 is provided with a connecting protrusion 101, and the other end is provided with a mounting groove 102, the connecting protrusion 101 matches the mounting groove 102, and the mounting groove 102 is a A waterproof groove 5 is provided on the side. After the connection protrusion 101 is docked with the installation groove 102, the root of the connection protrusion 101 is set inside the waterproof groove 5, and the waterproof glue 6 is injected into the waterproof groove 5. There are multiple The stabilizing steel bars 3 are in a "U" shape. One end of the drainage ditch 1 is provided with a connection protrusion 101, and the other end is provided with an installation groove 102. Multiple drainage ditches 1 are installed and spliced through the connection protrusion 101 and the installation groove 102. Between the connection protrusion 101 and the install...

Embodiment 2

[0056] Further illustrate in conjunction with embodiment 1, as Figure 1-12 As shown in the structure, the drainage ditch 1, the cover plate 2 and the dredging cover plate 10 are produced in the factory according to the drawings. The steel mesh sheet 9 and the stabilizing steel bar 3 are put into the drainage ditch mold first, and then the cement is poured into the mold to manufacture the drainage ditch 1.

[0057] Excavate and install the groove 8 at the installation place of the drainage ditch, and carry out the base tamping at the bottom of the installation groove 8. If the soil quality is relatively poor, it should be replaced and then compacted.

[0058] During the compaction process, do a good job of slope finding according to the direction of water flow in the gutter to ensure smooth water flow.

[0059] Use the hoisting equipment to hoist the drainage ditch 1 into the installation groove 8 , and splice the connecting protrusion 101 and the installation groove 102 of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com