A kind of method for preparing xylo-oligosaccharide from hemicellulose

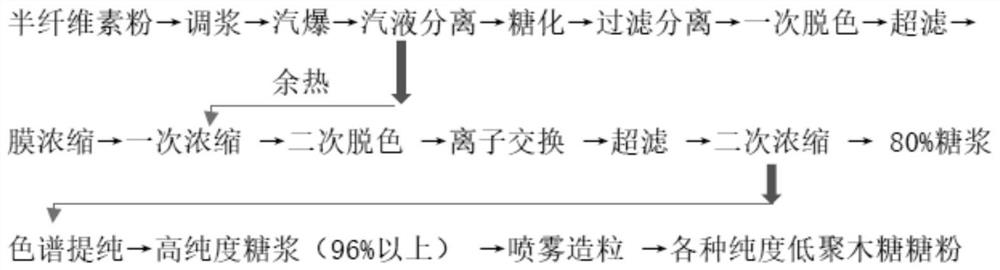

A technology of hemicellulose and xylooligosaccharides, which is applied in the preparation of oligosaccharides and sugar derivatives, chemical instruments and methods, etc., can solve the problems of poor recovery of waste heat and steam, low light transmittance of feed liquid, and large amount of sewage discharge and other problems, to achieve the effect of reducing acid and alkali consumption, reducing steam consumption, and reducing the amount of sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

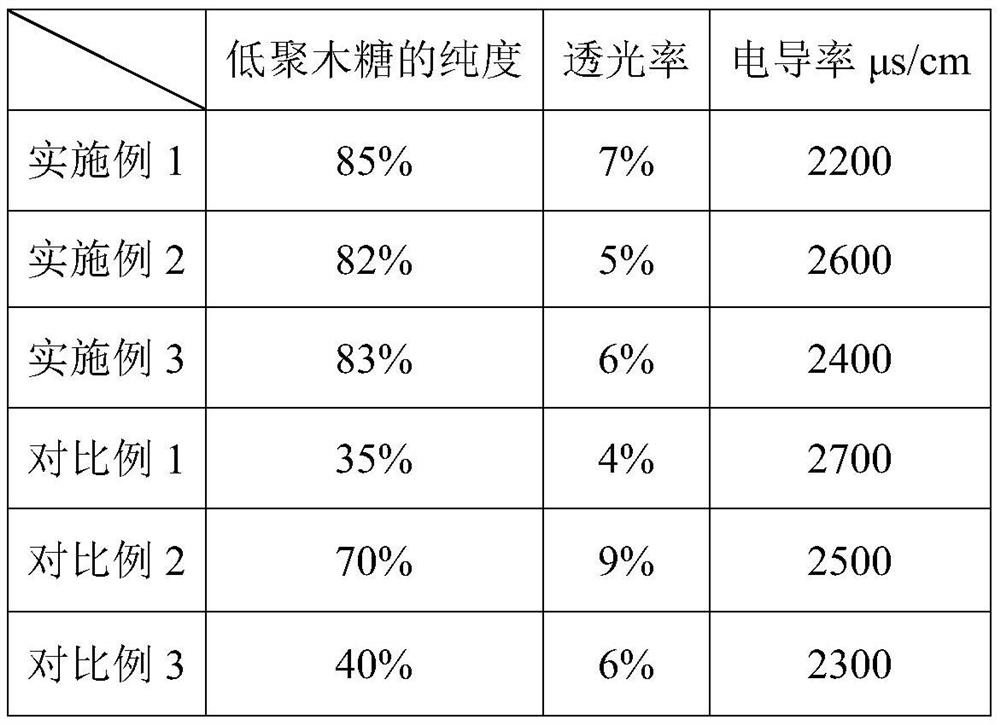

Embodiment 1

[0035] A method for preparing xylo-oligosaccharides from hemicellulose, comprising the following steps:

[0036] (1) First in the syrup tank (full volume 15m 3 ) Riga process water 12m 3 , and then add 2t hemicellulose powder (water content <15%), add acetic acid to adjust pH to 4.5, heat up to 82°C, stir and mix well; obtain a suspension of hemicellulose powder; adding other acids will affect enzymatic hydrolysis Purity of post-xylo-oligosaccharides.

[0037] Hemicellulose powder can be purchased through commercial channels, and can also be prepared according to conventional methods. In this example, the purchased hemicellulose powder is extracted from the pulping waste liquid of viscose fiber; the hemicellulose content is 85-90%, the moisture content is within 12%, and the ash content is less than 3.5%, the active ingredient high and the impurity content is small.

[0038] (2) Start the conveying pump, convey the suspension of hemicellulose powder obtained in step (1) to...

Embodiment 2

[0051] A method for preparing xylo-oligosaccharides from hemicellulose, comprising the following steps:

[0052] (1) First in the syrup tank (full volume 15m 3 ), add process water, then add hemicellulose powder (water content <15%), the mass ratio of hemicellulose powder and water is 1:6, add acetic acid to adjust pH to 5, heat up to 85 ° C, stir and mix evenly; The suspension of hemicellulose powder is obtained; the hemicellulose powder can be purchased through commercial channels, and can also be prepared according to conventional methods. In this example, the purchased hemicellulose powder is extracted from the pulping waste liquid of viscose fiber; the hemicellulose content is 85-90%, the moisture content is within 12%, and the ash content is lower than 3.5%, and the effective components are high. , the impurity content is small.

[0053] (2) Start the conveying pump, convey the suspension of hemicellulose powder obtained in step (1) to the booster ejector, open the ste...

Embodiment 3

[0067] A method for preparing xylo-oligosaccharides from hemicellulose, comprising the following steps:

[0068] (1) First in the syrup tank (full volume 15m 3 ), add process water, then add hemicellulose powder (water content <15%), the mass ratio of hemicellulose powder and water is 1:6, add acetic acid to adjust pH to 5, heat up to 90 ° C, stir and mix well; The suspension of hemicellulose powder is obtained; the hemicellulose powder can be purchased through commercial channels, and can also be prepared according to conventional methods. In this example, the purchased hemicellulose powder is extracted from the pulping waste liquid of viscose fiber; the hemicellulose content is 85-90%, the moisture content is within 12%, and the ash content is less than 3.5%, the active ingredient high and the impurity content is small.

[0069] (2) Start the conveying pump, convey the suspension of hemicellulose powder obtained in step (1) to the booster ejector, open the steam valve of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com