Gantry crane

A crane and gantry crane technology, applied in the field of hoisting machinery, can solve the problems of reducing the service life of the hoisting rope, high cost, complex structure, etc., and achieve the effects of perfect function, simple structure, and economical and reasonable layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

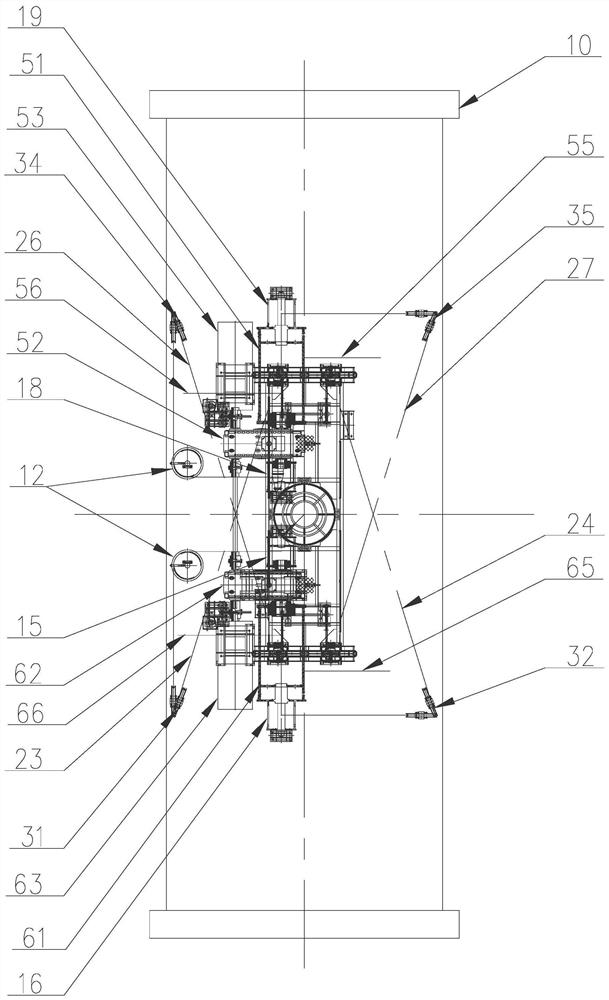

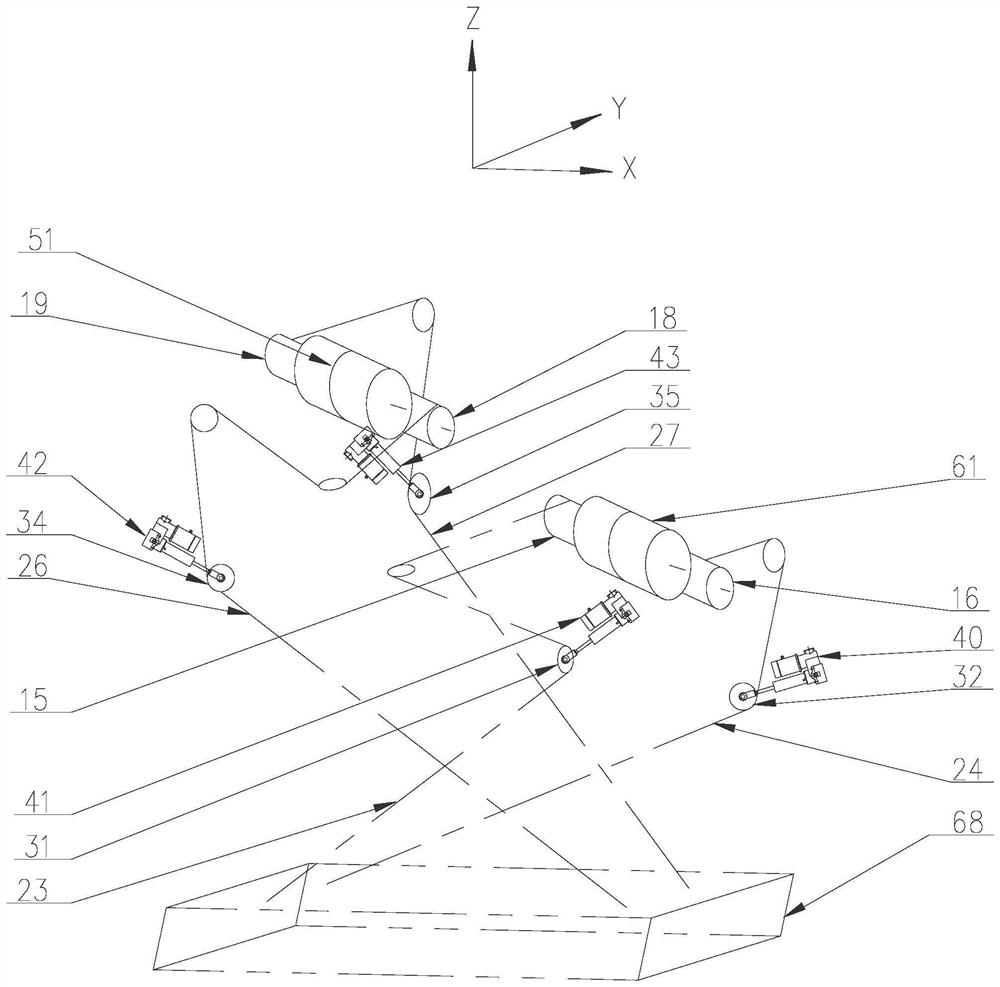

[0039] Such as figure 1 with figure 2 As shown, the gantry crane of this embodiment includes a spreader system, a trolley frame and two pairs of anti-rolling units, and a hoisting mechanism connecting the spreader system and the trolley frame is installed on the trolley frame.

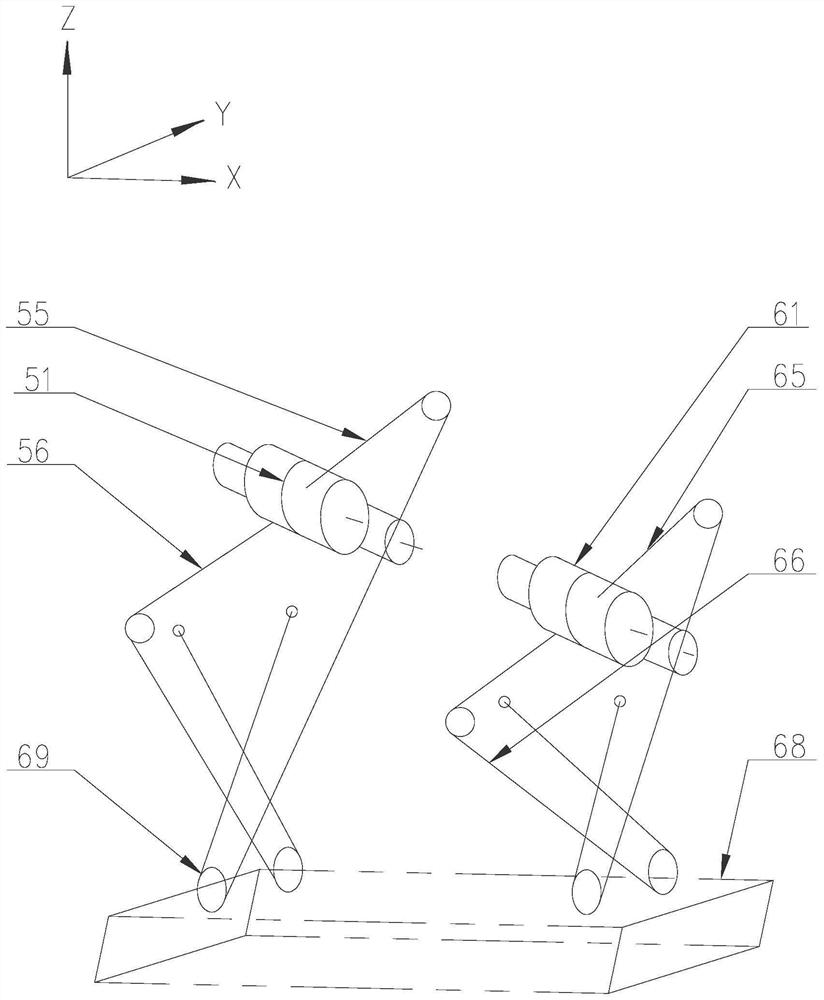

[0040] Such as image 3 As shown, the hoisting mechanism includes a hoisting drum, a hoisting rope wound on the hoisting drum, and two hoisting pulleys arranged on the spreader system. Let the axial direction of the lifting drum be the X direction, let the direction perpendicular to the horizontal plane and the X direction be the Y direction, let the lifting direction be the Z direction, and set the X direction along the direction of the cart or the direction of the trolley; The pulleys are arranged at intervals along the Y-axis direction; the two outgoing rope ends of the hoisting rope are respectively fixed on the trolley frame after bypassing the hoisting pulleys in the direction opposite to its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com