Mica sheet clamping and bending mechanism

A technology of bending mechanism and mica sheet is applied in the field of mica sheet winding machine, which can solve the problems of inconvenient arrangement and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific embodiments, but the present invention is not limited to these specific embodiments. Those skilled in the art will recognize that all alternatives, improvements, and equivalents may be included within the scope of the claims.

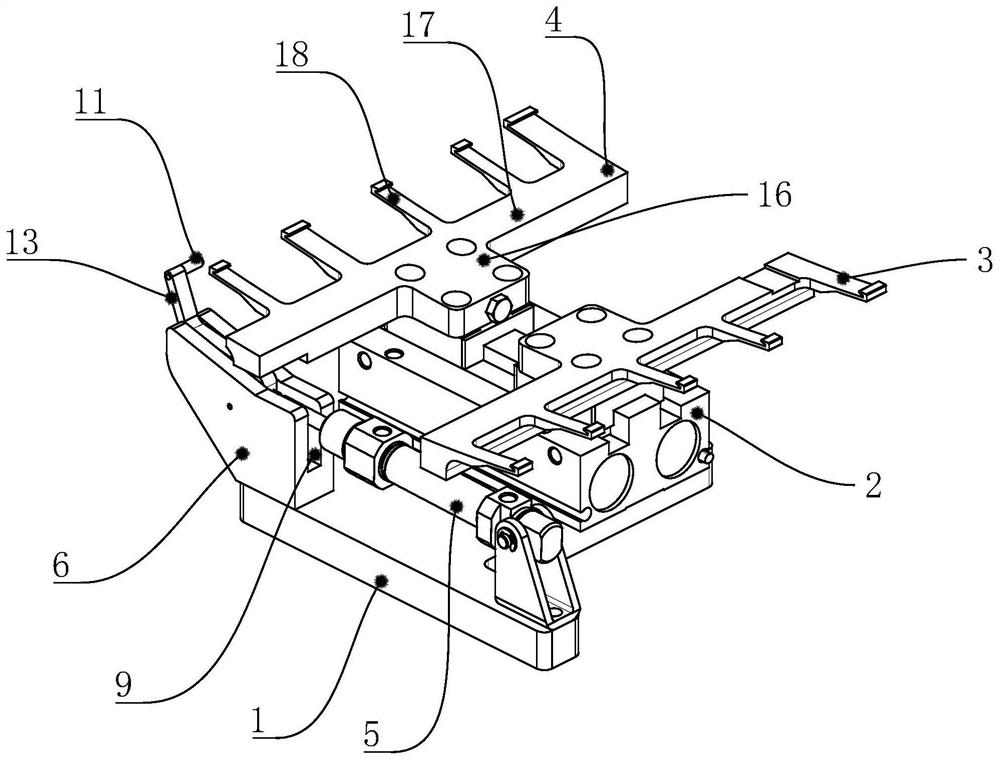

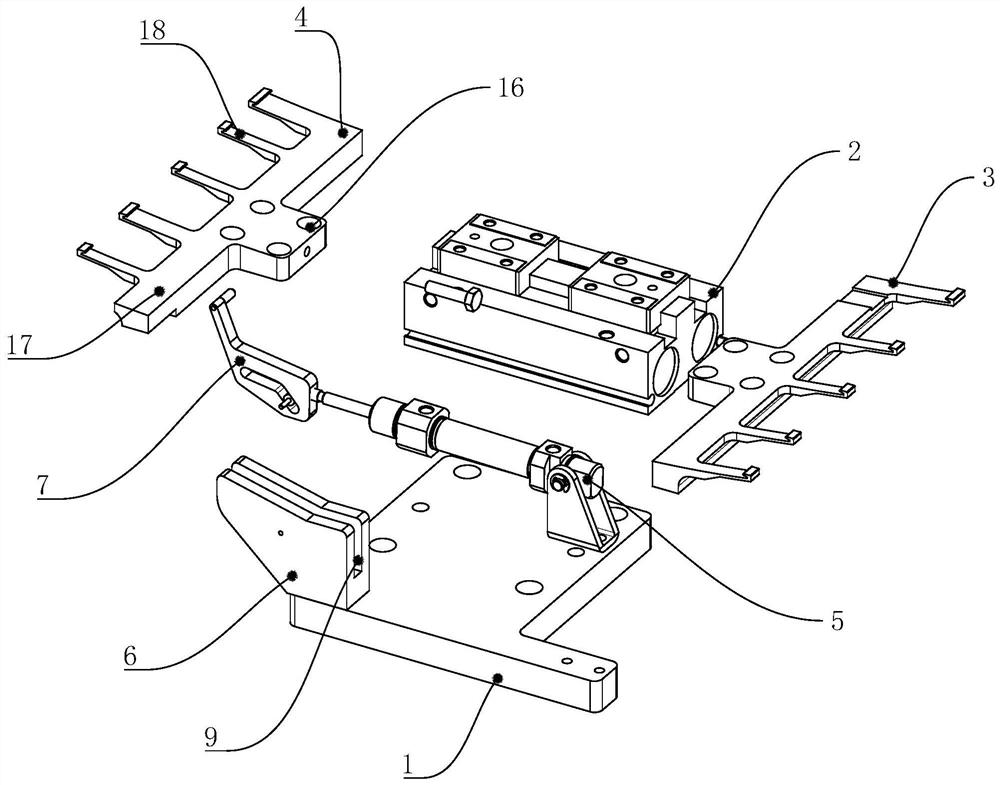

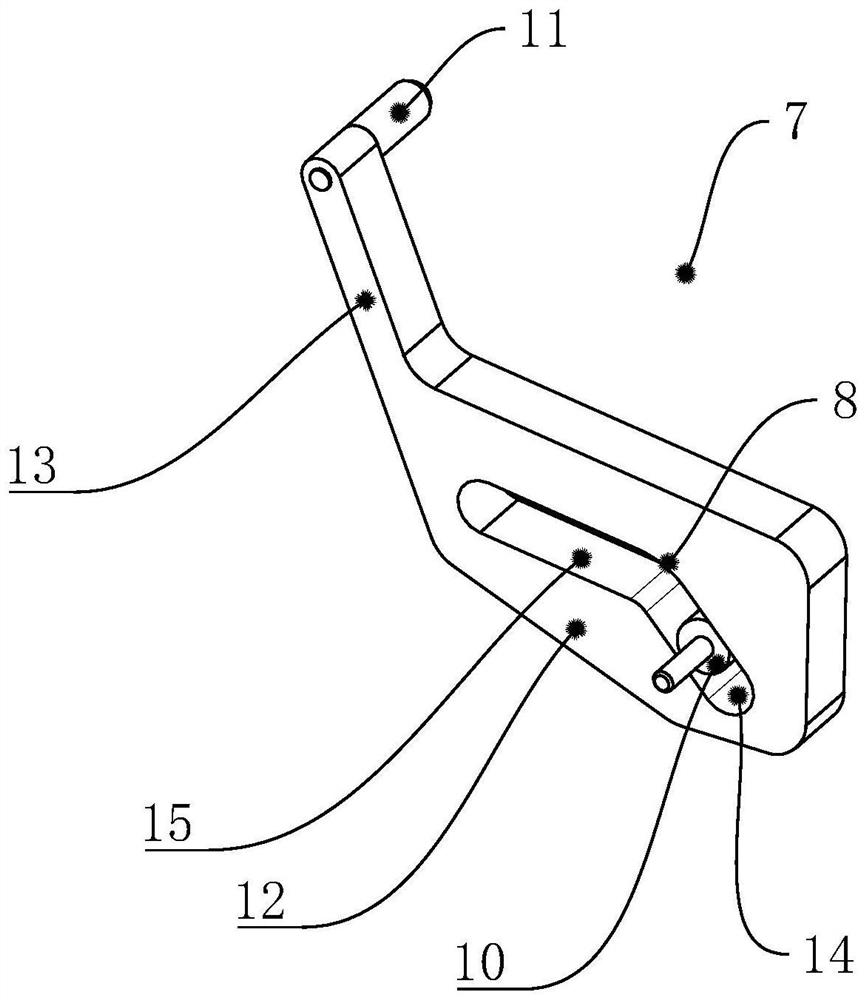

[0019] Such as Figure 1-5 As shown, the mica clamping bending mechanism is shown, including the grip disk 1, the clamping gas cylinder 2, the left pinch plate 3, the right pinch 4, the cartridge 5, the fixing seat 6, and the briquette 7, the clamping plate. The cylinder 2 is fixedly mounted on the grip disk 1, and the left pinch 3 and the right splint 4 are connected to two output terminals of the clamping air cylinder 2; the cartridge 5 and the fixing seat 6 Fixed on the same side of the grip plate 1 and located on the grip air cylinder 2, and there is a trajectory hole 8 on the cartridge 7; the fixing seat 6 is opened. A bearing 10 is provided in the baffle groove 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com