Feeding system of infusion bottle light inspection and encasement production line

A technology of checking and packing and production line, which is applied in the field of feeding system of the infusion bottle light checking and packing production line, can solve the problems of improved packing efficiency and high cost of robots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

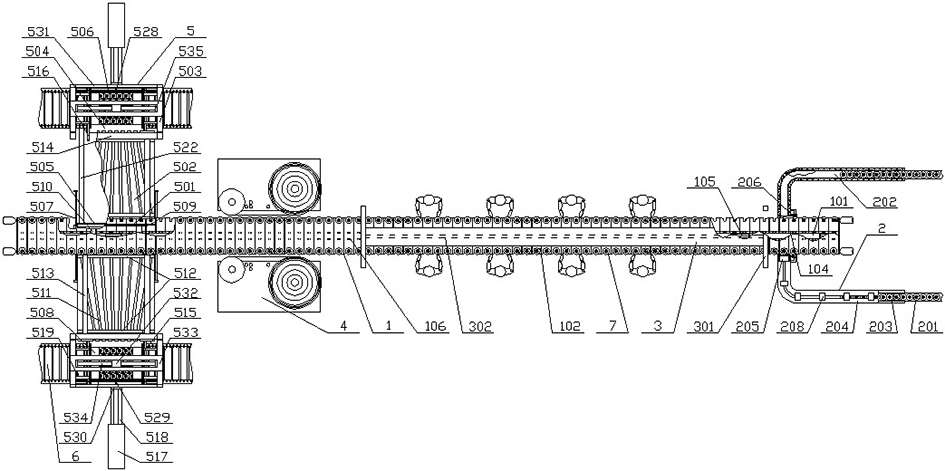

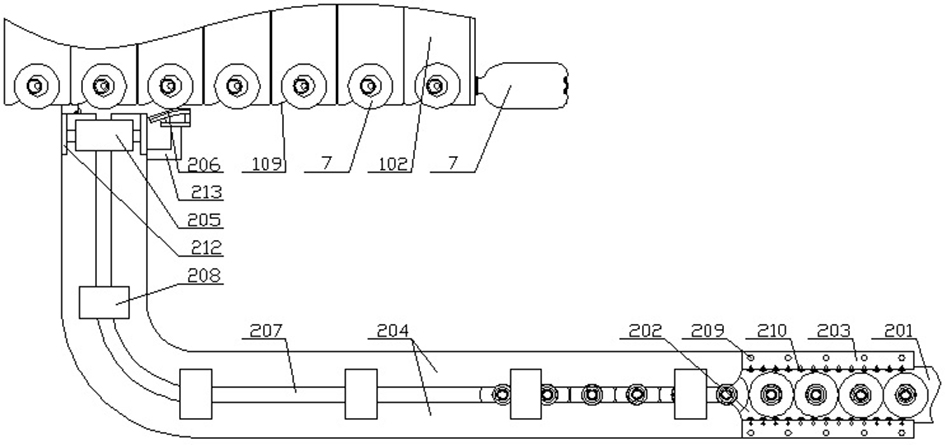

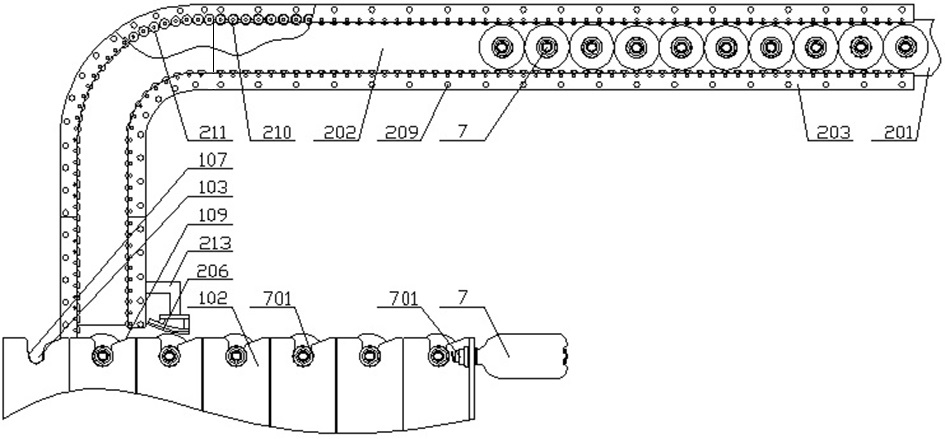

[0092] combine Figure 1~Figure 15 It can be seen that the feeding system of the infusion bottle light inspection and packing production line includes the bottle body conveying device 1 of the infusion bottle 7, and one side of the conveying device 1 is sequentially arranged along the conveying direction of the bottle body conveying device 1 and The bottle feeding conveyor 2, the light inspection device 3, the labeling device 4 and the boxing device 5 are conveyed and connected. The two ends of the endless conveying chain corresponding to the bottle conveying device 1 are respectively movably connected with the conveying base frame 101 of the bottle conveying device 1 through driving wheels. The transmission direction of the conveying chain plate unit 102 below is opposite, and the top and bottom are reversed. The infusion bottle 7 is connected to the end of the conveying chain plate unit 102 corresponding to the side of the bottle conveying device 1, and the bottle feed conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com