Bamboo chopstick fixed-length rolling forming component manufactured by high-end equipment

A technology of bamboo chopsticks and equipment, applied in the direction of special forming/shaping machines, manufacturing tools, forming/shaping machines, etc., can solve the problems of low production efficiency, heavy manual workload, waste of large raw materials, etc., and achieve saving of raw materials and labor The effect of small workload and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

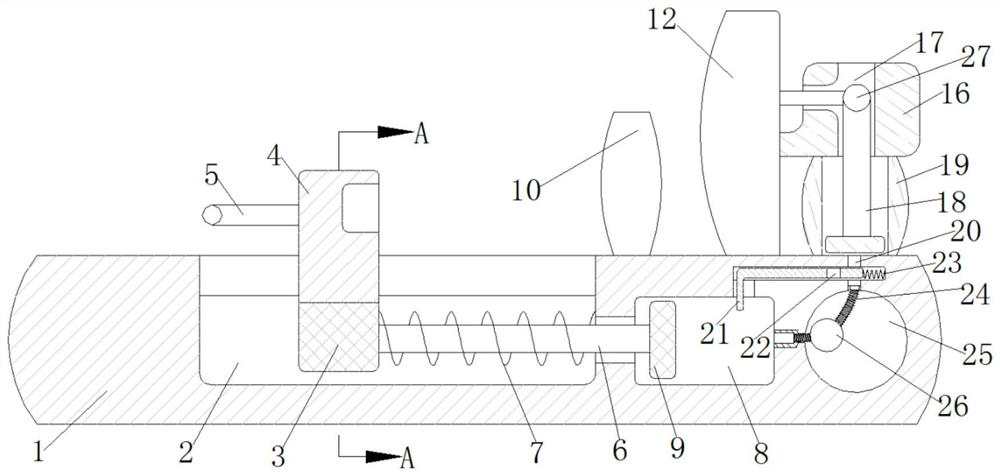

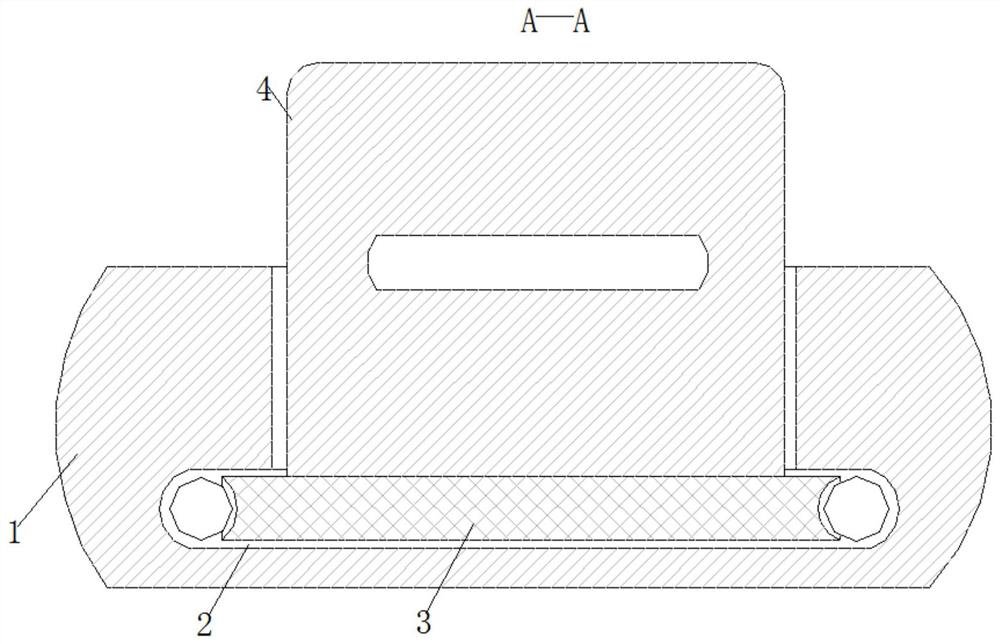

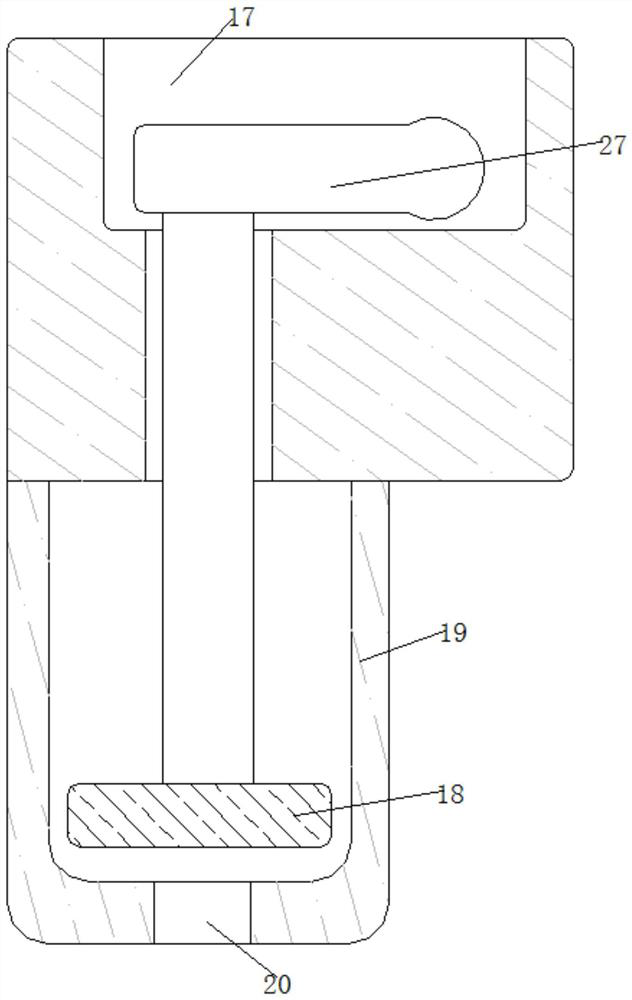

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0026] see Figure 1-5 , a bamboo chopsticks fixed-length roll-formed component manufactured by high-end equipment, including a bottom plate 1, a right-angle hole is arranged inside the bottom plate 1 and above the working tank 8, and a valve block 21 is movably inserted in the right-angle hole, and the valve A sealing hole 22 is provided in the middle of the upper end of the block 21, and the sealing hole 22 can cooperate with the round hole 20 to control the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap