Motor belt pulley pulling device

A technology of motor pulleys and telescopic devices, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of affecting disassembly, failure of pulling pulleys, difficult disassembly of pulleys, etc., and achieves the effects of preventing deformation, strong adaptability, and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

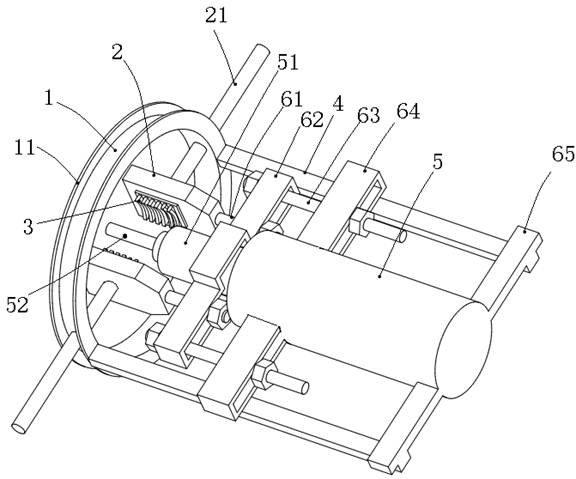

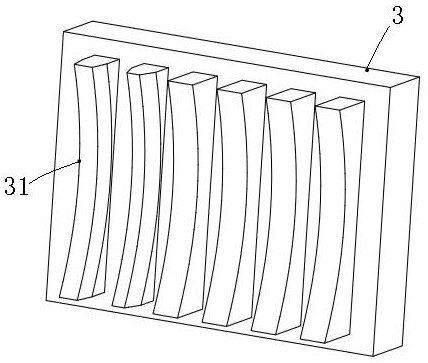

[0023] Motor pulley pulley, such as figure 1 with figure 2 As shown, at least two of the cuvers 2, including the circular array distribution, in particular, two junction clamp 2, which are both embedded in the inner side of the cuvers 2, and A bump 31 is provided with a pulley block 3; a splint rod 21 is mounted in the outer side of the pulleys 2, and the central pendulum rod 21 is in a fixed frame. 1 and with the fixture 1 thread;

[0024] A socket 52 is provided at the position between the cupping clamp 2, and the top rod 52 is located on the centerline of the circular array, and the position of the end rod 52 is secured to a telescopic device 5. One end of the top rod 52 is fixedly coupled to the telescopic rod 51 of the telescopic device 5 and is disposed with the telescoping rod 51; the first tilt rod 61 is provided, one end of the first lever 61. Another end of the first tie rod 61 stops on a fixed arrangement tie rod assembly, the first tilt rod 61 relays a radial sliding...

no. 2 example

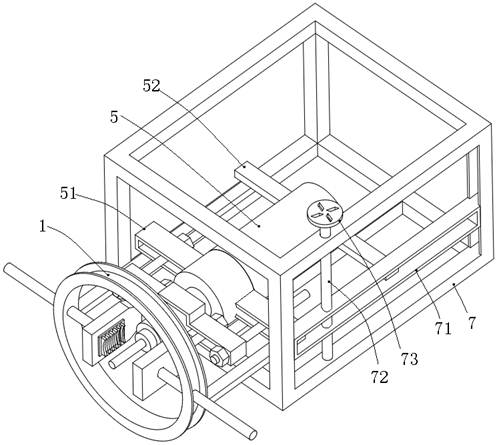

[0031] Other technical features are the same as in the first embodiment, combined image 3 As shown, the telescopic device 5 lifted down, and specifically, in the bracket 7, a beam 71 is provided, and both ends of the beam 71 are slidably mounted on the bracket 7, in the stent. 7 Turn the vertical rod 72, the middle portion of the filament 72 penetrates through the beam 71 and threads with the beam 71, and the hand wheel 73 is fixed at the top end of the rod 72, and the telescopic The device 5 is fixed to the beam 71. The first sliding rail 64 and the connecting plate 65 are fixed to the cylinder of the telescopic device 5, the first sliding rail 64, and the connecting plate 65 located at both ends of the cylinder of the telescopic device and The beam 71 is fixedly connected.

no. 3 example

[0033] Other technical features are the same as in the first embodiment or the second embodiment, combined Figure 4 with Figure 5 As shown, the tie rod assembly includes a plurality of first sliding rails 64 corresponding to the first lever 61, the first lever 61 recesses and the first sliding rail 64 corresponding to it. The first sliding rail 64 slides together, and the first sliding rail 64 is fixedly coupled to the telescopic device.

[0034] The working principle of the present invention is to rotate the rod by rotating the hand wheel, thereby allowing the beam to drive the telescopic device, put the equivalent height of the belt wheel into the cuvet splint, turn the splint splitter to close each other, and make the hug The wheelcarca card is connected to the pulley, the telescopic device extends out the telescopic rod, the telescopic rod drives the top rod and holds the rotation shaft of the center position of the pulley, and the rotor is jealous out of the pulley, thereby ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com