Machining engraving equipment

A technology of engraving equipment and machining, applied in metal processing equipment, metal processing machine parts, manufacturing tools, etc., can solve problems such as health effects, hinder the formability of works, affect aesthetics, etc., to enhance work efficiency and increase image clarity degree, the effect of reducing the degree of inclination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

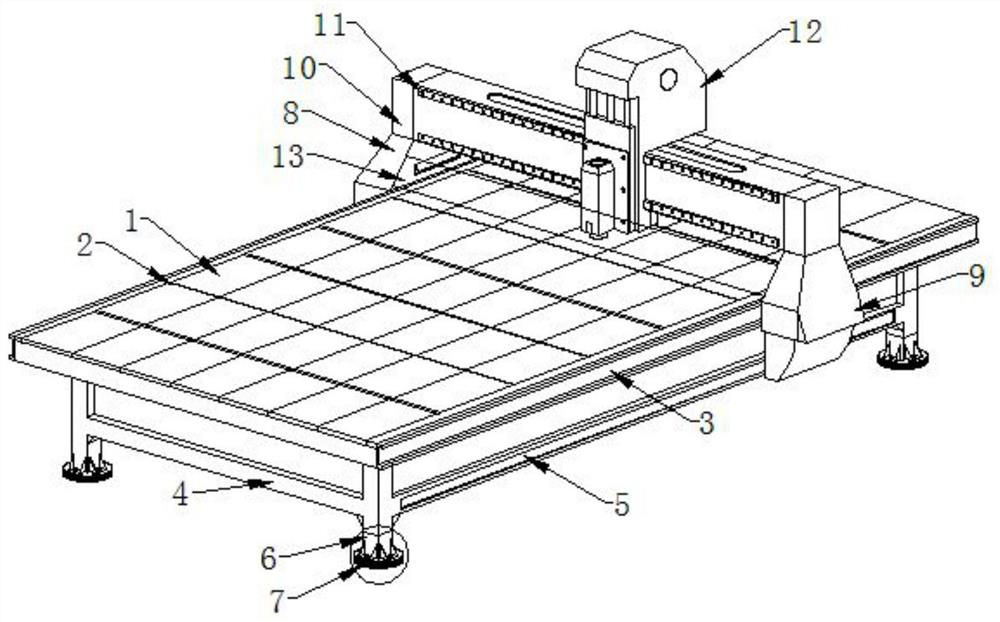

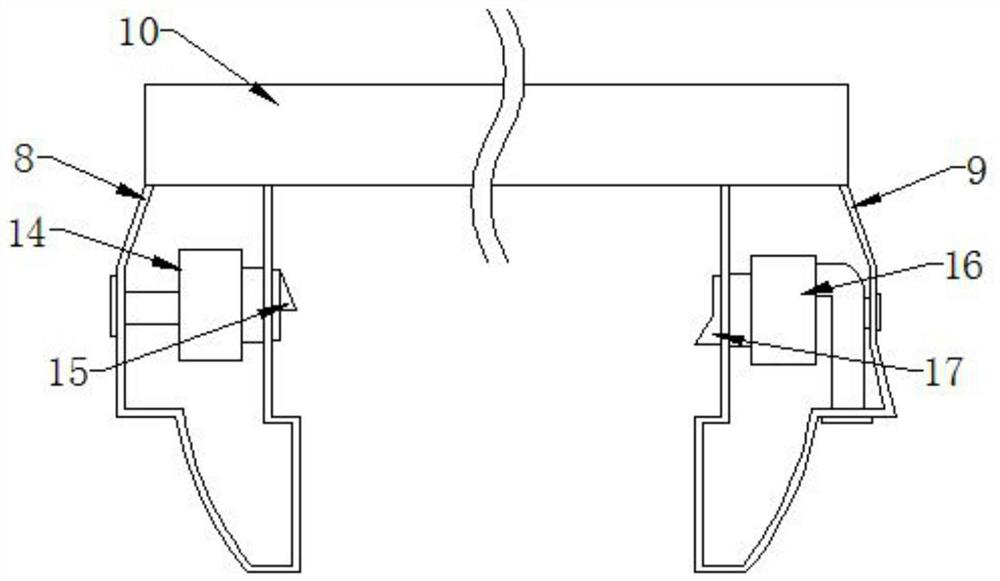

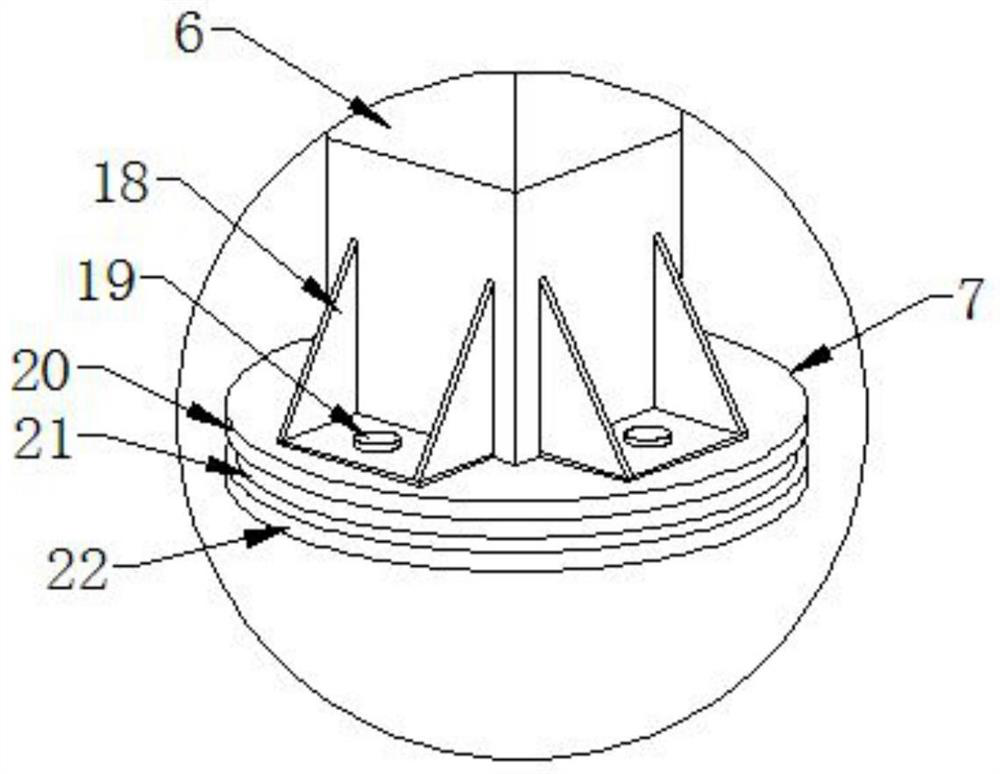

[0023] Such as Figure 1-4 As shown, the present invention provides a kind of machining engraving equipment, including a panel 1, the surface of the panel 1 is provided with a groove 2, and the groove 2 is arranged in a horizontal shape, and the two ends of the panel 1 are installed with a first slide Slot 3, the bottom end of the panel 1 is equipped with a bracket 4, the two sides of the bracket 4 are provided with a second chute 5, the four corners of the bracket 4 are provided with feet 6, and the bottom of the feet 6 is installed There is a base 7, a left side slider 8 is installed on one side of the panel 1, a right side slider 9 is installed on the other side of the panel 1, and a beam 10 is installed on the top of the left side slider 8, so A side surface of the crossbeam 10 is provided with a slide rail 11, the middle part of the crossbeam 10 is provided with an engraving host 12, and a dust-proof strip 13 is installed between the left side slider 8 and the right side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com