Full-automatic magnetic levitation classificator

A technology of magnetic levitation and concentrator, which is applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of easy running of tailings, uneven overflow of tailings, uneven water supply, etc., and achieve high efficiency of equipment Sorting, efficiency improvement, and the effects of not running tails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

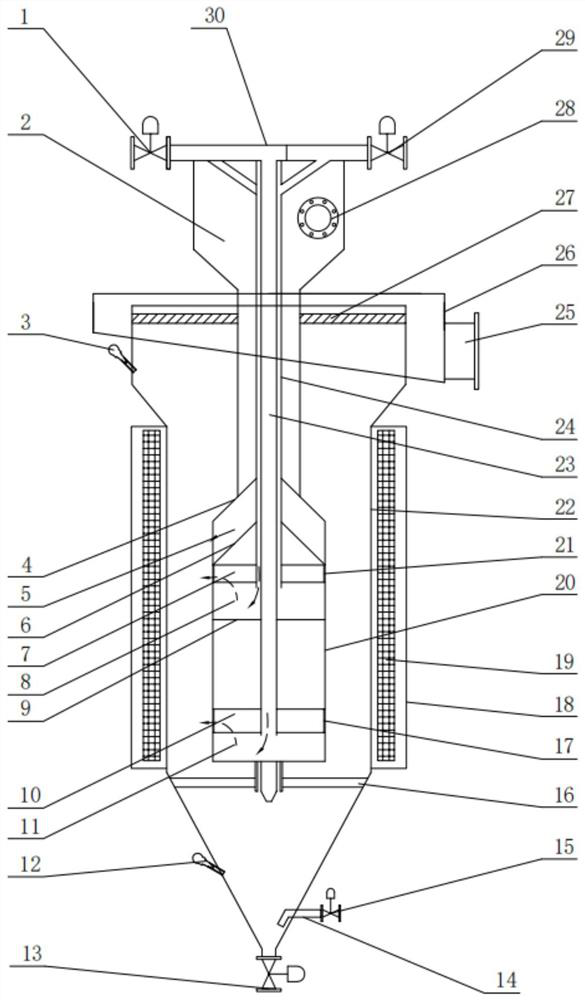

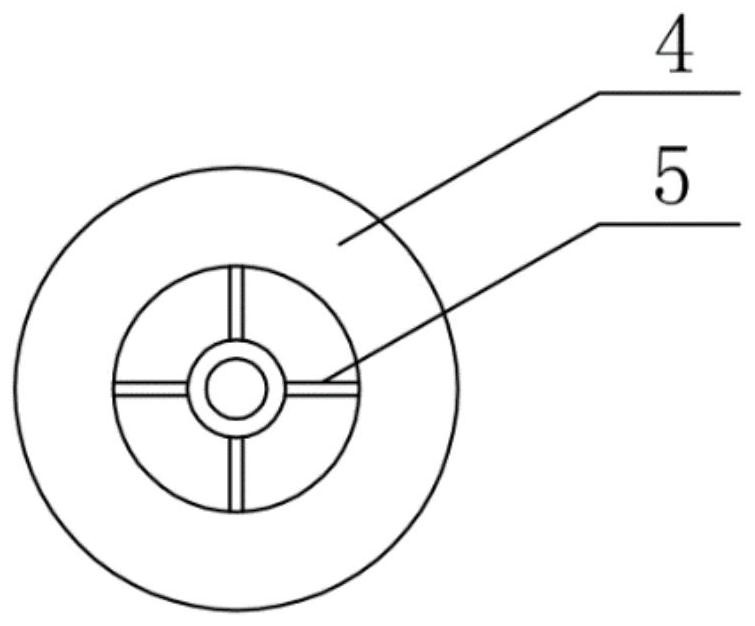

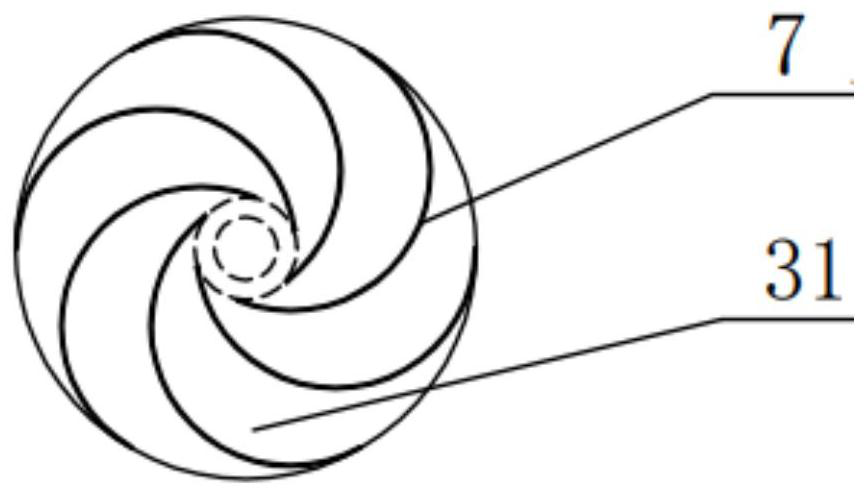

[0041] refer to Figure 1 to Figure 8 , the application provides a fully automatic magnetic levitation concentrator, including ore feeding device 2, ore separating device, water supply device 20, overflow tank 26, sorting cylinder 22 and magnetic system 19; the ore feeding device 2 extends coaxially into the sorting tube 22, the upper end of the sorting tube 22 is connected with the ore feeder 2 through a support plate 27, which plays a role of supporting connection between the two, and the lower end of the ore feeder 2 is connected with the separator The ore separation device is connected, and the ore separation device is provided with a number of pulp channels conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com