Ore crushing equipment for metal smelting

A technology of ore crushing and metal smelting, which is applied in the direction of grain processing, etc., can solve the problems of ore that cannot be cut into small pieces, difficulties in ore crushing of ore equipment, and low efficiency of ore crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

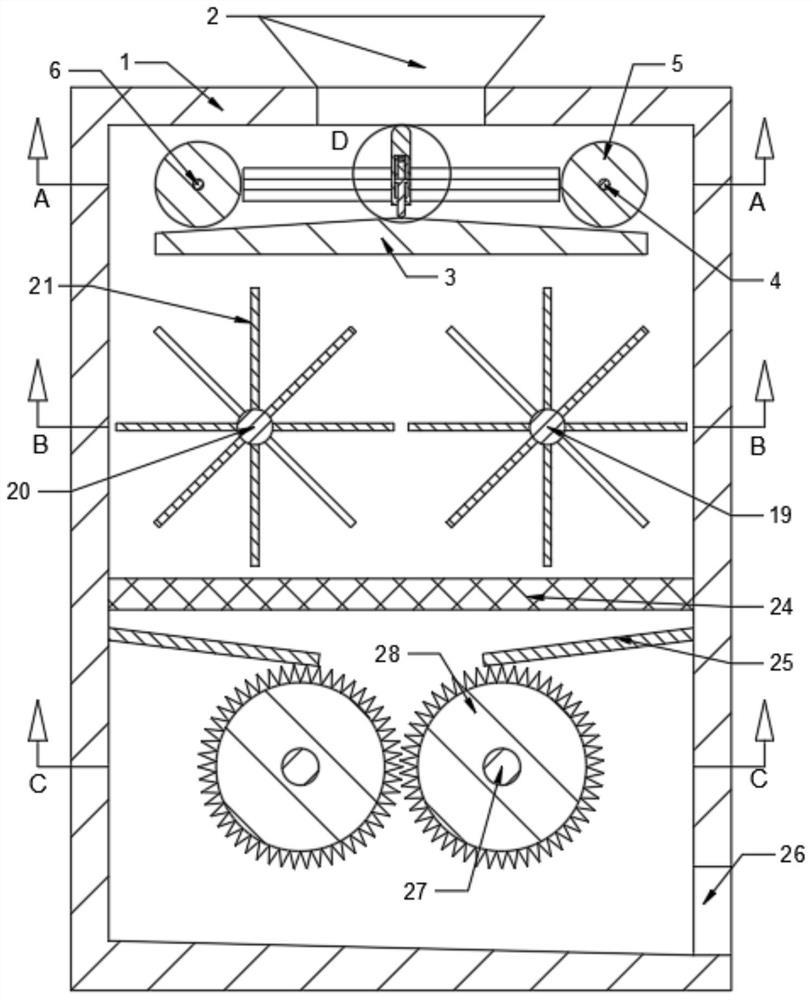

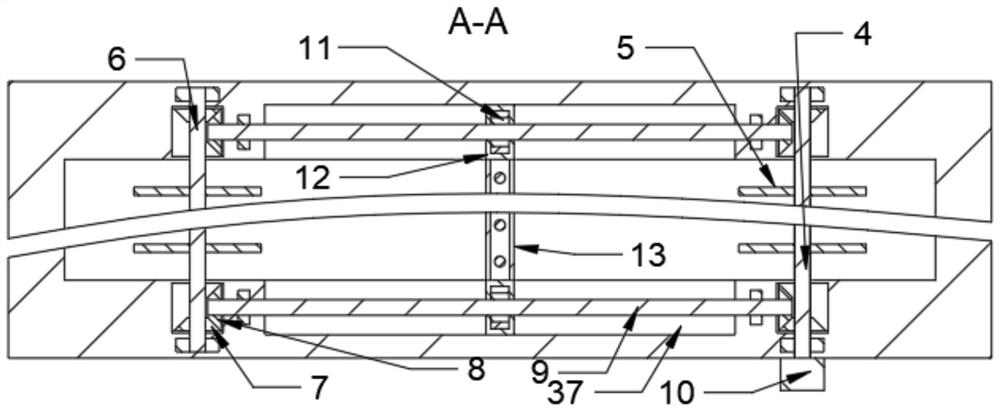

[0024] see figure 1 , figure 2 , Figure 5 with Image 6 , in the embodiment of the present invention, a kind of ore crushing equipment for metal smelting, comprising equipment body 1; the middle part of the equipment body 1 is provided with a crushing device; the upper part of the equipment body 1 is fixedly installed with a guide plate 3; Both sides above the guide plate 3 are symmetrically provided with a second rotating shaft 6 and a first rotating shaft 4, and the two ends of the second rotating shaft 6 and the first rotating shaft 4 are rotatably installed in the device body 1; the first rotating shaft 4 and the second rotating shaft Multiple groups of cutting discs 5 are evenly distributed and fixedly installed on 6; first bevel gears 7 are fixedly installed on both ends of the first rotating shaft 4 and the second rotating shaft 6; device; the upper middle part of the guide plate 3 is movable against a T-shaped plate 15; the upper part of the T-shaped plate 15 is s...

Embodiment 2

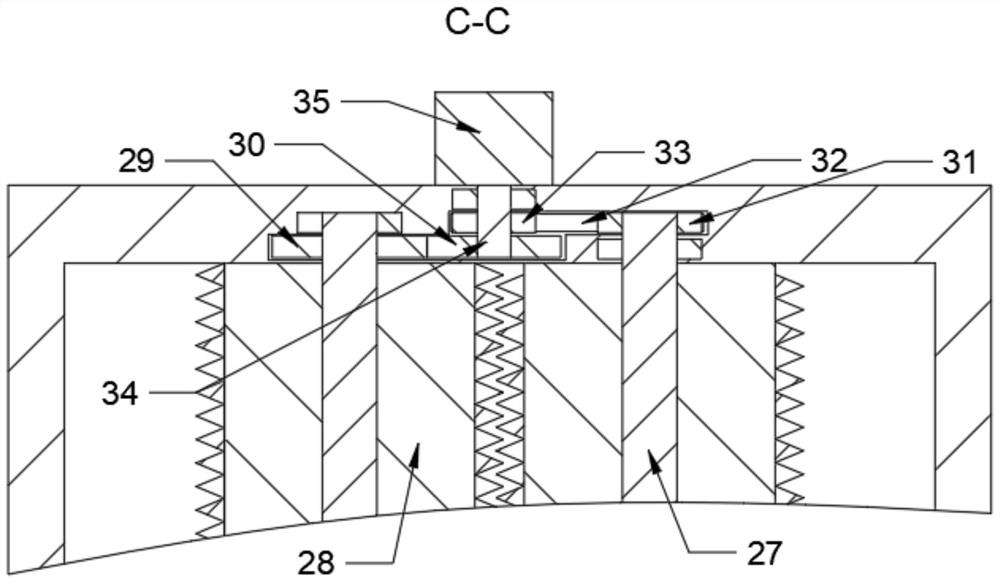

[0030] refer to figure 1 with Figure 4 , the grinding device includes a fifth shaft 27, a drum 28, a first gear 29, a second gear 30, a third gear 31, a second chain 32, a fourth gear 33, a sixth shaft 34 and a third motor 35; The fifth rotating shaft 27 is symmetrically rotated and mounted on both sides of the lower part of the device body 1; the fifth rotating shaft 27 is fixedly sleeved with a roller 28; the roller 28 is provided with teeth, and the teeth on the two groups of rollers 28 are mutually meshing; one end of the fifth rotating shaft 27 is respectively fixedly installed with a first gear 29 and a third gear 31; the first gear 29 is transmission meshed with a second gear 30; 34; the sixth rotating shaft 34 is rotatably installed in the lower part of one side of the device body 1; the end of the sixth rotating shaft 34 far away from the second gear 30 is connected with a third motor 35, and the third motor 35 is fixedly installed On the outside of the device body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com