Automatic shelling and screening device for shelled medicinal materials

A screening device and technology for medicinal materials, applied in solid separation, separation of solids from solids with air flow, grain processing, etc., can solve the problems of cumbersome separation of medicinal materials and broken shells, troublesome manual shelling, damage to internal medicinal materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

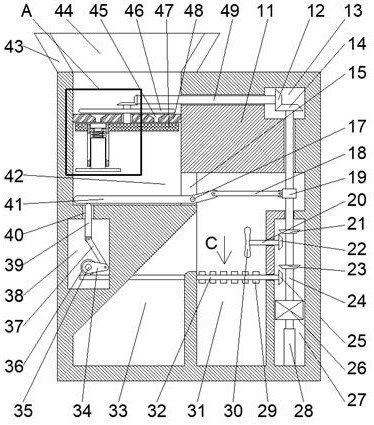

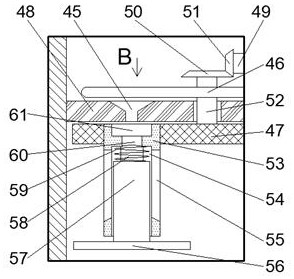

[0014] Combine below Figure 1-4 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

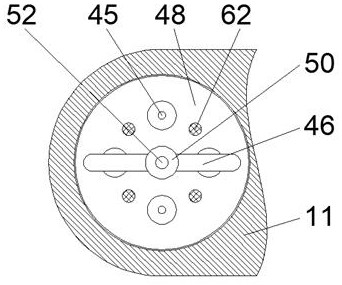

[0015]An automatic shelling and screening device for medicinal materials with shells according to the present invention comprises a shelling box 11, a shelling chamber 42 with an upward opening is arranged in the shelling box 11, and a middle plate 48, the upper and lower rotation of the center of the middle plate 48 is connected with a shelling shaft 52; , the lower end of the stirring rod 46 abuts against the upper end of the middle plate 48, with the shelling shaft 52 as the center, an annular array distribution on the middle plate 48 is provided with drain grooves 45 through up and down, and the middle plate 48 upper circular arrays are distributed with magnets 62, the lower end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com