Immersion type cooling equipment

A cooling equipment, immersion technology, which is applied to the structural parts of electrical equipment, cooling/ventilation/heating renovation, electrical components, etc. , to achieve the effect of improving heat dissipation and liquid return efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

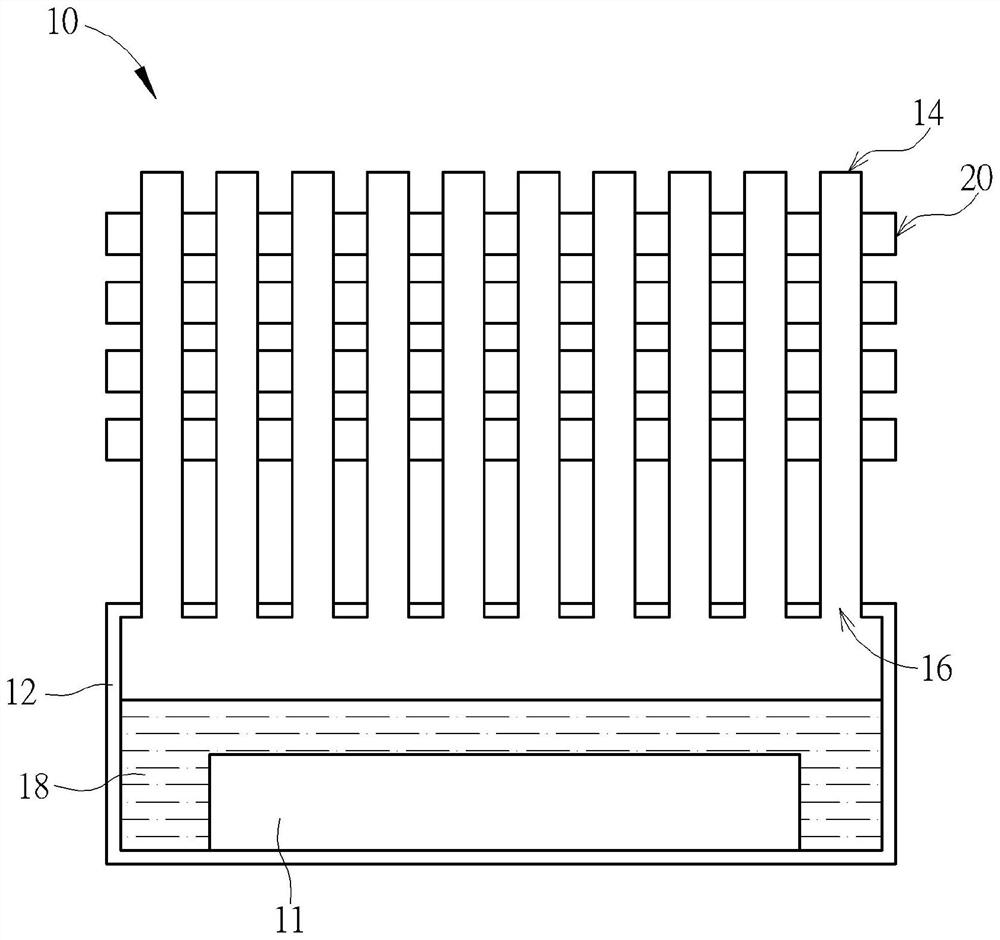

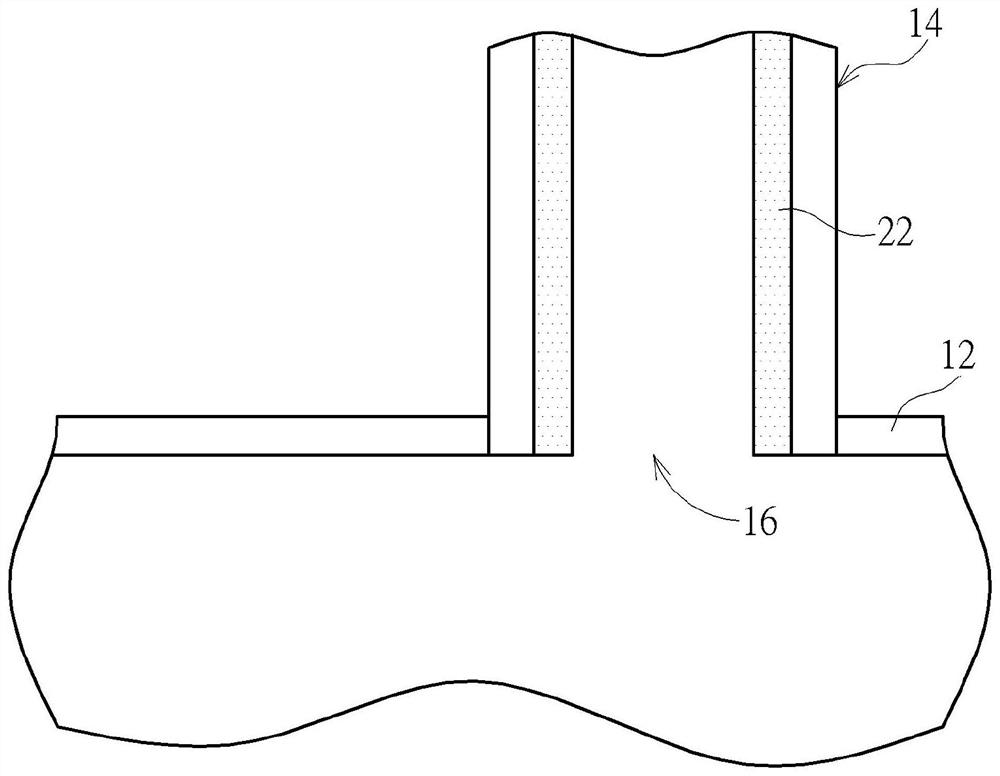

[0011] see figure 1 , which is a schematic cross-sectional view of an immersion cooling device 10 proposed according to an embodiment of the present invention. The immersion cooling device 10 is used to cool a heating element 11 (such as a blade server, disk array, etc.) heat dissipation, such as figure 1 As shown, the immersion cooling device 10 includes a heating element 11 , a cooling liquid tank 12 and a plurality of metal pipes 14 . The coolant tank 12 can be a coolant storage tank chamber commonly used in immersion cooling equipment (its related tank chamber design is common in the prior art, so it will not be repeated here) and has a plurality of upper exhaust ports 16 , the cooling liquid tank 12 can be used to store a cooling liquid 18 and accommodate the heating element 11, so that the heating element 11 can be immersed in the cooling liquid 18, wherein the cooling liquid 18 can be an inert dielectric liquid commonly used for immersion cooling (such as mineral oil,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com