Ultralow temperature motor

An ultra-low temperature, motor housing technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as the effect of not reaching ultra-low temperature, poor working stability, affecting performance, etc., to achieve simple structure and stable work. Strong performance and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

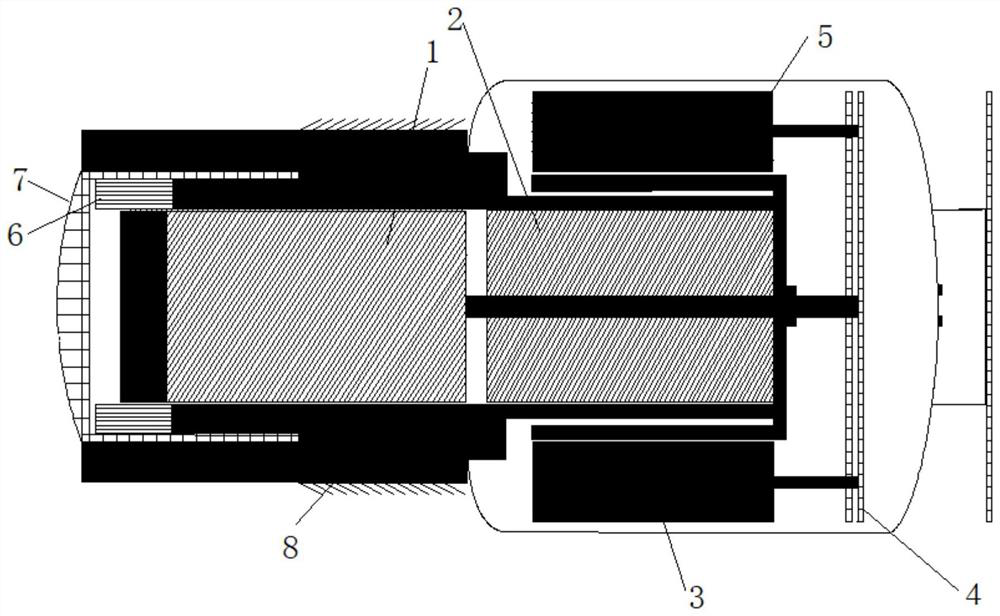

[0016] Such as figure 1 As shown: an ultra-low temperature motor, including a motor housing 7, a high-performance vertical motor 3, a displacement piston 2 and a compression piston 1 are arranged in the motor housing 7, and the motor housing at the cold end is filled with helium gas, and the straight height Performance The vertical motor 3 drives the displacement piston 2 and the compression piston 1 to move circularly along the axial direction; a neodymium-iron-boron magnet coil 5 is arranged inside the motor housing at the displacement piston. The NdFeB magnet coil 5 and the high-performance vertical motor 3 are respectively arranged at both ends of the motor shaft, and the NdFeB magnet coil 5 , the vertical motor 3 and the motor shaft are all fixedly connected with the leaf spring 4 . A honeycomb copper sheet 6 is arranged in the motor housing at the cold end. A heat-conducting annular copper sheet 8 is arranged outside the shell of the replacement piston. The heat-conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com