BIM-based air duct system prefabricating method

A technology of air ducts and pipe fittings, applied in the field of BIM-based air duct system prefabrication, which can solve problems such as construction errors, positioning errors, and low utilization rate of prefabricated air duct systems in civil engineering, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

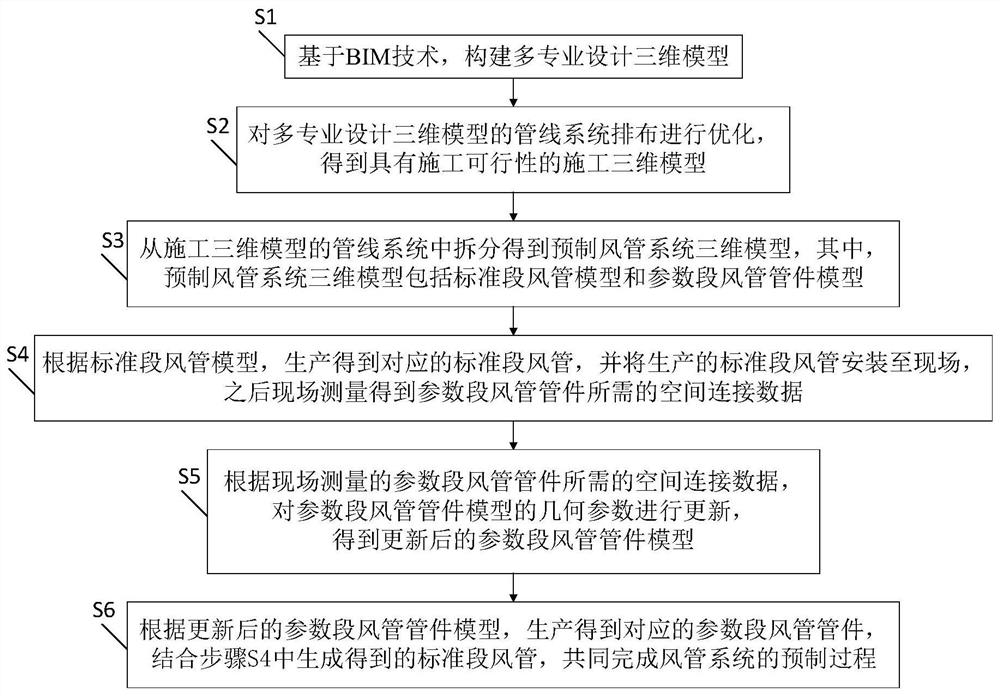

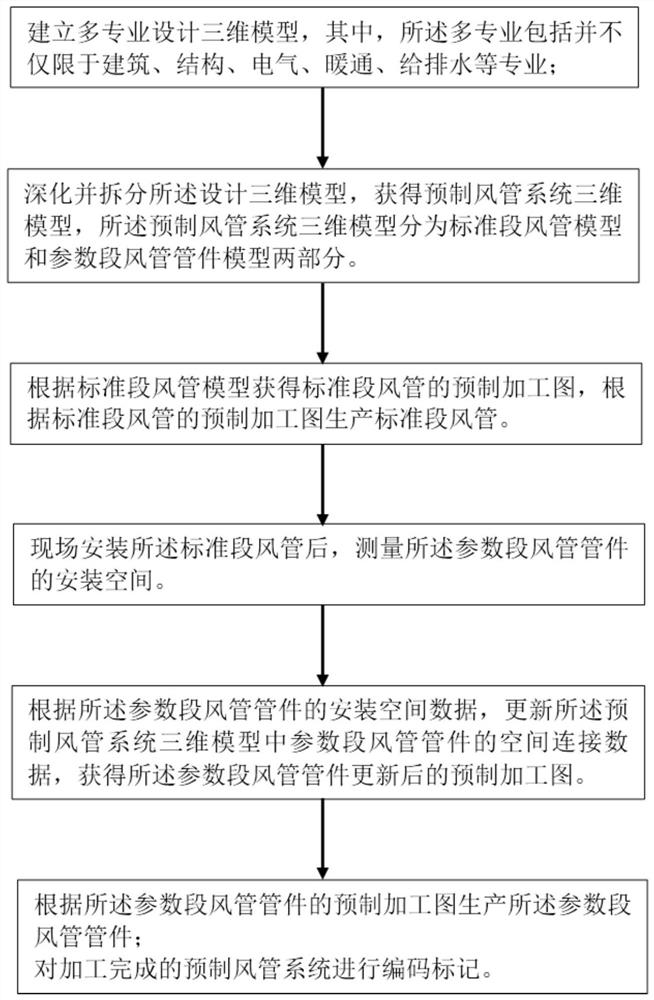

[0039] Such as figure 1 As shown, a BIM-based air duct system prefabrication method includes the following steps:

[0040] S1. Based on BIM technology, construct a 3D model for multi-discipline design. The 3D model for multi-discipline design includes but not limited to 3D model for architectural design, 3D model for structural design, 3D model for electrical design, 3D model for HVAC design, and 3D model of drainage professional design;

[0041] S2. Optimize the pipeline system layout of the multi-disciplinary design 3D model, and obtain a construction 3D model with construction feasibility. Specifically, according to the principle of comprehensive layout of electromechanical pipelines, the installation process of pipeline equipment and the feasibility of operation and maintenance, multi-disciplinary Design the pipeline system layout of the 3D model and optimize it, or optimize the pipeline system layout of the multi-disciplinary design 3D model according to the results of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com