Fabricated building construction device

A building construction and prefabricated technology, applied in the construction, building structure, processing of building materials, etc., can solve the problems of the extruded board not reaching 90 degrees, the collapse of the wall board, the equipment damage of the supporting device, etc. Practicality and applicability, the effect of reducing the impact force and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

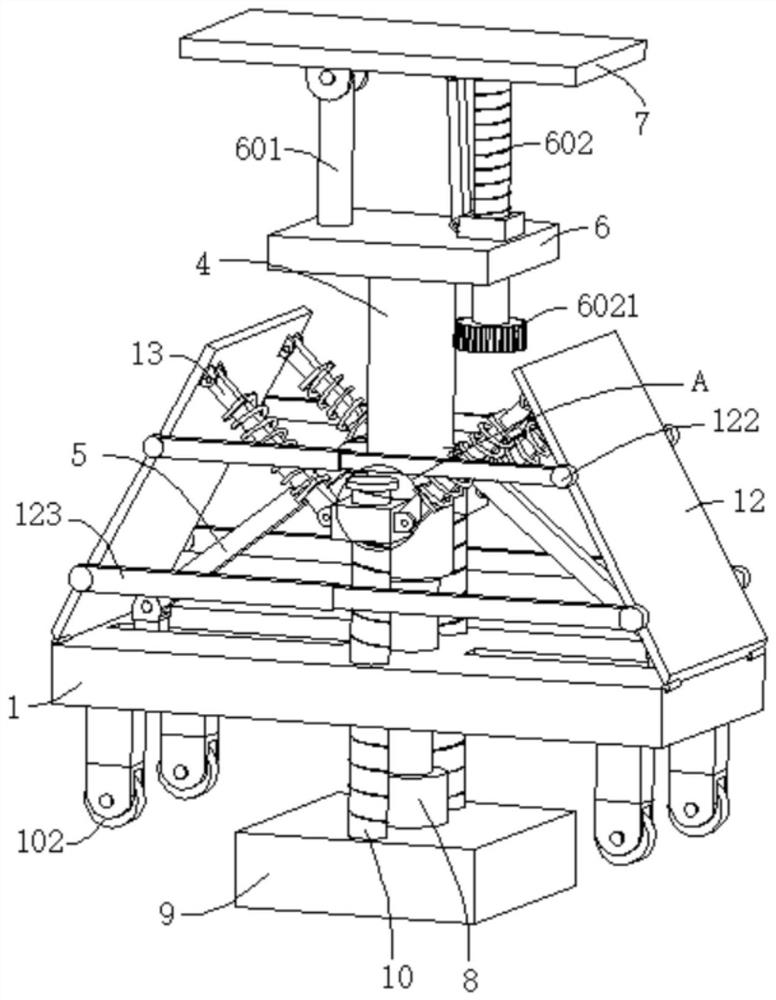

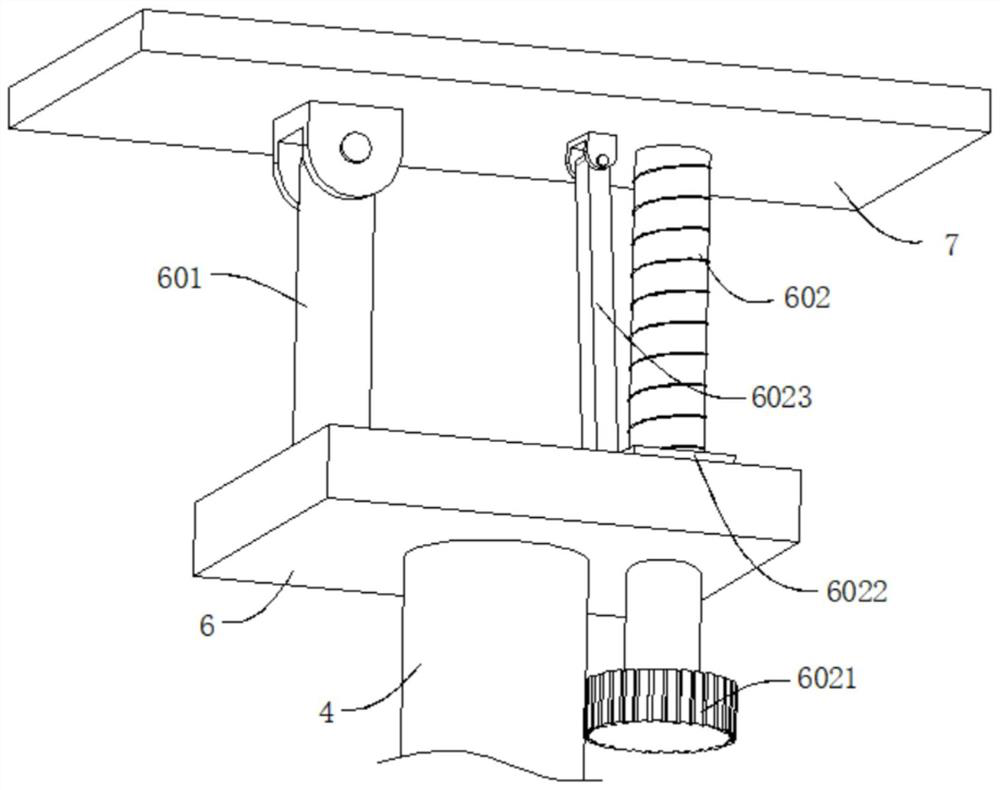

[0033] refer to Figure 1-6 , a prefabricated building construction device, comprising a working board 1, the bottom wall of the working board 1 is connected with a roller 102, a cavity is dug in the working board 1, a motor 2 is connected to the inner wall of the cavity, and the output end of the motor 2 passes through the working The plate 1 is also connected with a rotating shaft 201, the end of the rotating shaft 201 away from the motor 2 is connected with a first screw 3, the outer wall of the first screw 3 is threadedly connected with a threaded pipe 4, and the outer walls of both sides of the working plate 1 are dug with chute 101, the chute The inner wall of 101 is slidably connected with a slider 1011, the slider 1011 and the outer wall of the threaded pipe 4 are respectively connected with a first U-shaped plate 1012 and a second U-shaped plate 401, and the first U-shaped plate 1012 and the second U-shaped plate 401 are connected Connecting plate 5 is arranged, and t...

Embodiment 2

[0038] refer to figure 1 , a prefabricated building construction device, which is basically the same as Embodiment 1, furthermore, the bottom of the working board 1 is connected to a cylinder 8, and the end of the cylinder 8 away from the working board 1 is fixedly connected to a base 9.

[0039] Since the device is supporting the assembly of the wallboard, the rollers 102 at the bottom may move, resulting in a poor support effect of the device. By setting the cylinder 8, the cylinder 8 is controlled to work, so that the output power rod of the cylinder 8 pushes the working plate 1 and The distance between the bases 9 becomes large, so that the bases 9 contact the ground, and the rollers 102 move up with the working plate 1 and leave the ground, so as to prevent the device from shaking arbitrarily when supporting work, and improve the stability of the device.

Embodiment 3

[0041] refer to figure 1 , figure 2 , Figure 5 , Image 6 and Figure 7 , a prefabricated building construction device, which is basically the same as Embodiments 1 and 2, furthermore, the outer walls on both sides of the base 9 are connected with baffles 12 through hinges, and a supporting mechanism is connected between the baffles 12 and the base 9 .

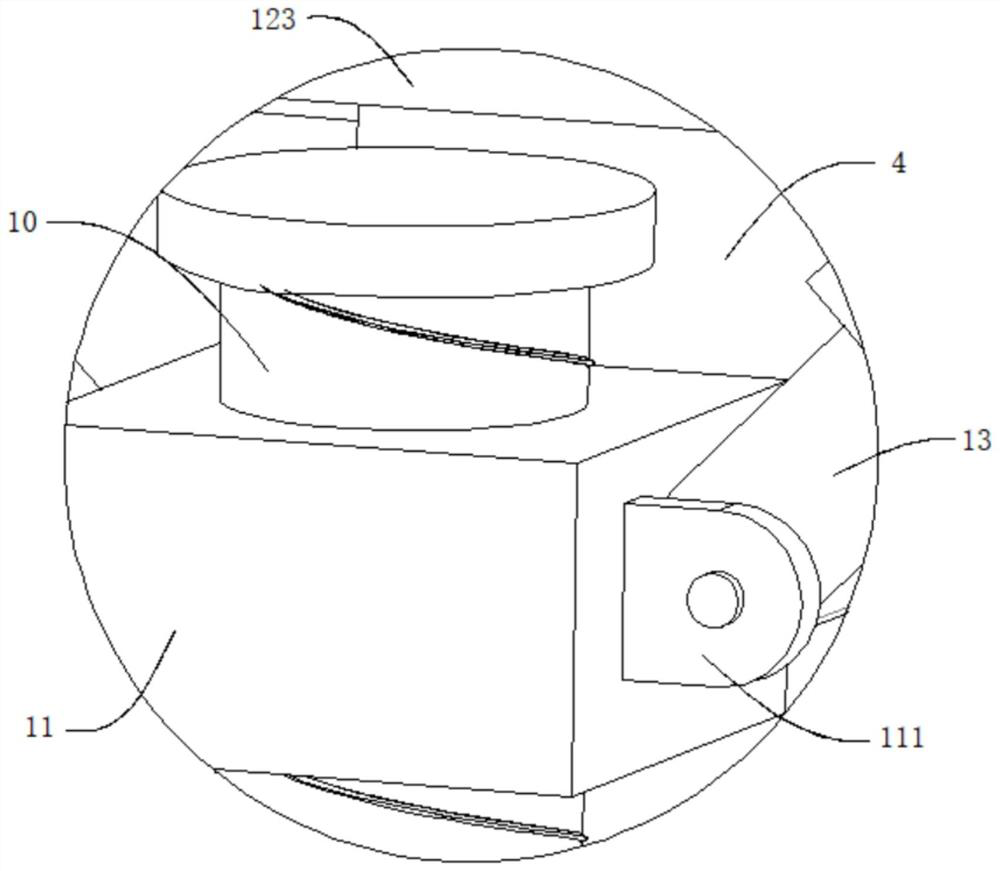

[0042] The support mechanism includes a third screw rod 10, which is rotatably connected in the base 9 through bearings, and the third screw rod 10 is threadedly connected with the working plate 1, and the outer wall of the third screw rod 10 is threadedly connected with a second sleeve 11, and the second sleeve A support plate 13 is connected between the cylinder 11 and the baffle plate 12 .

[0043] Both ends of the support plate 13 are respectively movably connected with a third U-shaped plate 111 and a fourth U-shaped plate 121, the third U-shaped plate 111 is fixedly connected to the outer wall of the second sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com