Method for producing POY varieties by FDY equipment

A technology of equipment and varieties, applied in the field of spinning, can solve the problem of low POY full winding rate, etc., and achieve the effect of reducing the stretching ratio, reducing stretching, and high full winding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

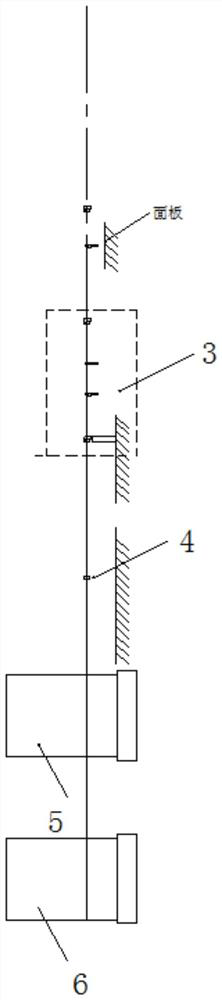

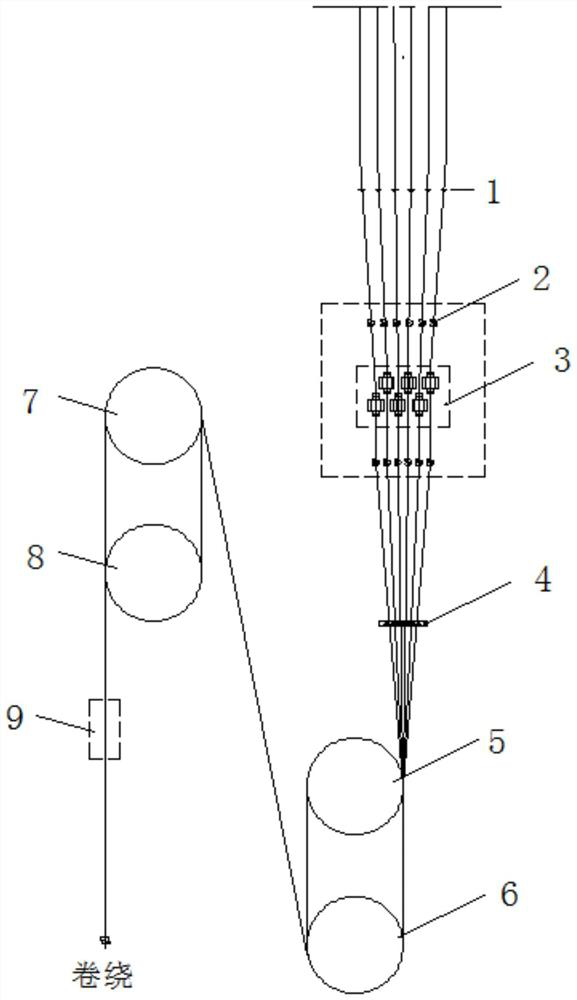

[0033] A method for FDY equipment to produce POY varieties, the process flow of the FDY equipment is to pass the tow downwards through the wire guide 1, the first wire guide hook 2, the pre-networker 3, the splitting rod 4, the first The drafting roller 5, the second drafting roller 6, the third drafting roller 7, the fourth drafting roller 8 and the main network device 9 are wound and formed by a winding device to obtain the finished product of FDY. The first drafting The speed of roll 5 and second draft roll 6 is 3400m / min, and the speed of described third draft roll 7 and the 4th draft roll 8 is 4300m / min; Described FDY equipment produces POY kind method, including the following steps:

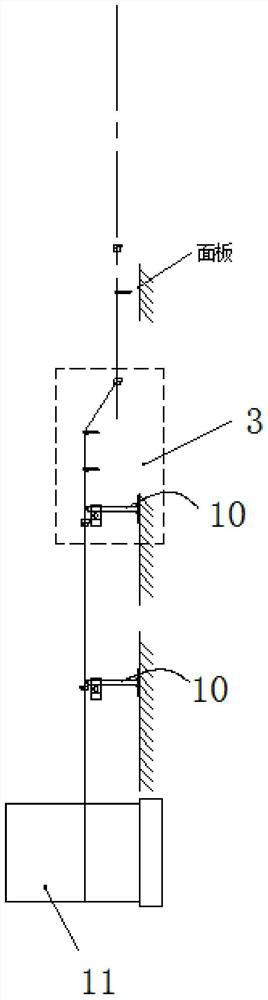

[0034] 1. A base 10 is provided on the FDY equipment corresponding to the position of the pre-netting device 3 and the splitting rod 4, and the described pre-netting device 3 and the splitting rod 4 are respectively located on the base 10 and located on the first guide wire hook The center...

Embodiment 2

[0038] A method for FDY equipment to produce POY varieties, the process flow of the FDY equipment is to pass the tow downwards through the wire guide 1, the first wire guide hook 2, the pre-networker 3, the splitting rod 4, the first The drafting roller 5, the second drafting roller 6, the third drafting roller 7, the fourth drafting roller 8 and the main network device 9 are wound and formed by a winding device to obtain the finished product of FDY. The first drafting The speed of roll 5 and second draft roll 6 is 3500m / min, and the speed of described third draft roll 7 and the 4th draft roll 8 is 4400m / min; Described FDY equipment produces POY kind method, including the following steps:

[0039] 1. A base 10 is provided on the FDY equipment corresponding to the position of the pre-netting device 3 and the splitting rod 4, and the described pre-netting device 3 and the splitting rod 4 are respectively located on the base 10 and located on the first guide wire hook The center...

Embodiment 3

[0043] A method for FDY equipment to produce POY varieties, the process flow of the FDY equipment is to pass the tow downwards through the wire guide 1, the first wire guide hook 2, the pre-networker 3, the splitting rod 4, the first The drafting roller 5, the second drafting roller 6, the third drafting roller 7, the fourth drafting roller 8 and the main network device 9 are wound and formed by a winding device to obtain the finished product of FDY. The first drafting The speed of roll 5 and the second draft roll 6 is 3600m / min, and the speed of the third draft roll 7 and the fourth draft roll 8 is 4500m / min; the FDY equipment produces POY varieties method, including the following steps:

[0044] 1. A base 10 is provided on the FDY equipment corresponding to the position of the pre-netting device 3 and the splitting rod 4, and the described pre-netting device 3 and the splitting rod 4 are respectively located on the base 10 and located on the first guide wire hook The center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com