High-performance carbon nano/MXene composite fiber and preparation method thereof

A composite fiber, carbon nanotechnology, applied in fiber processing, conductive/antistatic filament manufacturing, wet spinning, etc., can solve the problems of high electrical conductivity, mechanical strength, and high metal content, achieve high electrical conductivity, and simple process operation. , the effect of high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

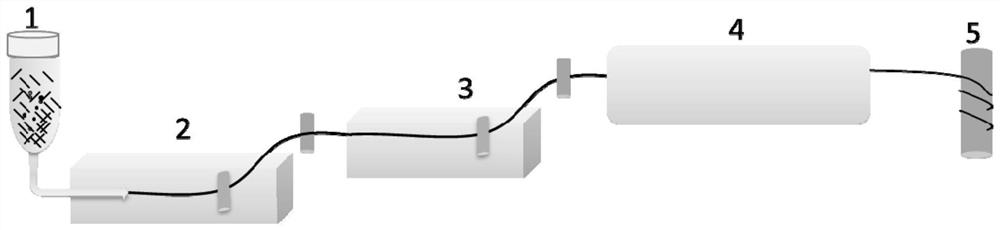

Method used

Image

Examples

Embodiment 1

[0048] Carbon nanotube / MXene composite fiber

[0049] Add 10 g of LiF into 200 mL of HCl solution with a concentration of 9 mol / L, stir at 35° C. for 30 min to fully dissolve it, and obtain an etching solution. Then, 10 g of Ti3AlC2 powder with a size of 2 μm was added to the etching solution, and stirred for 24 hours, so that Al was etched away. Finally, add deionized water to wash until the solution gradually changes from acidic to neutral (pH is 6), so as to obtain a two-dimensional lamellar MXene aqueous dispersion. The two-dimensional lamellar MXene aqueous dispersion is concentrated by suction filtration to make it The concentration is 25mg / mL.

[0050] Add 1 g of carbon nanotube powder (2 layers, 0.5 μm in length) to 200 mL of MXene dispersion so that the mass ratio of Ti3AlC2 to carbon nanotubes is 5:1. Then add sodium lauryl sulfate dispersing agent to make its concentration 0.5wt% of the obtained carbon nanotube / MXene dispersion slurry, and stir for 1 h to obtain c...

Embodiment 2

[0054] Carbon nanotube / MXene composite fiber

[0055] Add 10 g of LiF into 200 mL of HCl solution with a concentration of 9 mol / L, stir at 35° C. for 30 min to fully dissolve it, and obtain an etching solution. Then, 10 g of Ti2AlC powder with a size of 3 μm was added to the etching solution, and stirred for 24 hours, so that Al was etched away. Finally, add deionized water to wash until the solution gradually changes from acidic to neutral (pH is 6), so as to obtain a two-dimensional lamellar MXene aqueous dispersion. The two-dimensional lamellar MXene aqueous dispersion is concentrated by suction filtration to make it The concentration is 20mg / mL.

[0056] Add 1 g of carbon nanotube powder (the number of layers is a single layer and the length is 0.8 μm) to 400 mL of MXene dispersion, so that the mass ratio of Ti3AlC2 to carbon nanotubes is 8:1. Then add sodium dodecylbenzene sulfonate dispersing agent so that its concentration is 1.0wt% of the obtained carbon nanotube / MXe...

Embodiment 3

[0060] Graphene / MXene composite fiber

[0061] Add 10 g of LiF into 200 mL of HCl solution with a concentration of 9 mol / L, stir at 35° C. for 30 min to fully dissolve it, and obtain an etching solution. Then, 10 g of Ti3AlC2 powder with a size of 2 μm was added to the etching solution, and stirred for 24 hours, so that Al was etched away. Finally, add deionized water to wash until the solution gradually changes from acidic to neutral (pH is 6), so as to obtain a two-dimensional lamellar MXene aqueous dispersion. The two-dimensional lamellar MXene aqueous dispersion is concentrated by suction filtration to make it The concentration is 25mg / mL.

[0062] Add 1 g of graphene powder (2 layers, 0.3 μm in size) into 200 mL of MXene dispersion so that the mass ratio of Ti3AlC2 to graphene is 5:1. Then add sodium lauryl sulfate dispersion aid, make its concentration be 1.5wt% of the obtained carbon nanometer / MXene dispersion slurry, stir 1h, obtain graphene / MXene dispersion slurry. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com