Intelligent vertical-compressing brick tea making machine

A tea pressing and brick machine technology, which is applied in tea processing before extraction, packaging, food forming, etc., can solve the problems of long cleaning time, difficult cleaning, and long production cycle, so as to achieve diversified functions and save labor costs , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

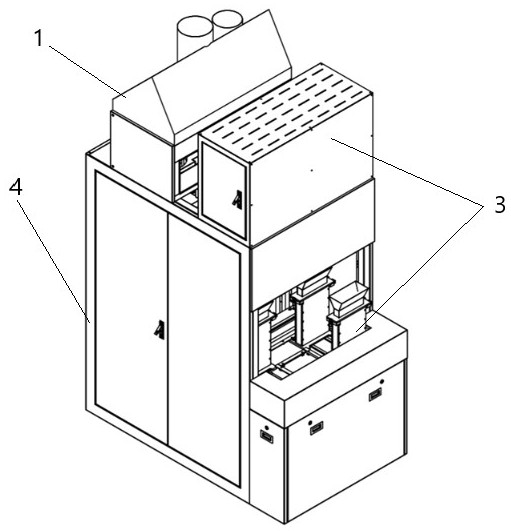

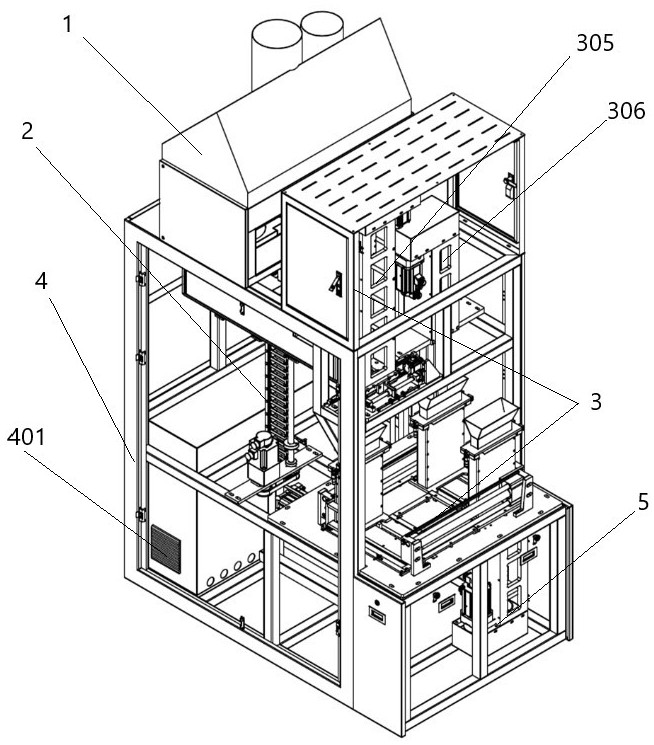

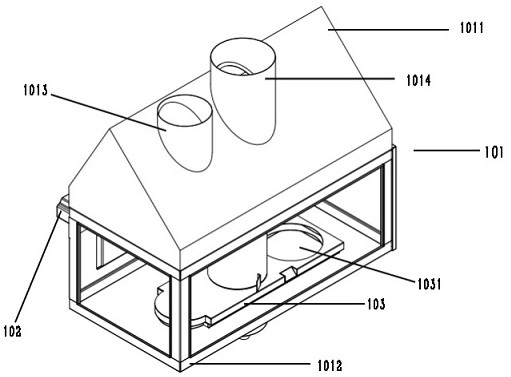

[0070] see figure 1 and figure 2 , the intelligent vertical tea brick pressing machine provided by the present invention includes a frame body 4 and a tea steaming mechanism 1 , a tea delivery mechanism 2 and a tea brick pressing mechanism 3 arranged on the frame body 4 . The tea delivery mechanism 2 is located at the bottom of the tea steaming mechanism 1 and communicates with the tea steaming mechanism 1 , and the tea delivery mechanism 2 communicates with the tea brick pressing mechanism 3 . The frame body 4 is provided with a loose tea inlet and a tea brick outlet; the loose tea inlet is connected with the tea steaming mechanism 1; the frame body 4 is also provided with a steam generating mechanism;

[0071] see figure 1 and figure 2 , in this embodiment, the frame body 4 includes a frame and a panel installed on the frame. The frame body 4 is a sealed cylindrical body structure as a whole, and an electric control box 401 is arranged at the inner bottom of the frame ...

Embodiment 2

[0084] see Figure 7-10 , on the basis of Embodiment 1, the tea delivery mechanism 2 includes a housing, a screw delivery assembly and a delivery drive assembly 211; the delivery drive assembly 211 is placed on the housing; connected.

[0085] see Figure 11 , in this embodiment, the screw conveying assembly includes a screw shaft 212 and an auger screw blade 213 arranged on the screw shaft 212; the screw shaft 212 is connected with the conveying drive assembly 211; Auger screw blade; the screw shaft is connected with the conveying drive assembly;

[0086] In this embodiment, the helix angle of the auger helical blade 213 is 10°; the pitch of the auger helical blade 213 is 60 mm; the diameter of the auger helical blade 213 is 150 mm; the diameter of the screw shaft 212 is 100 mm.

[0087]The above is the optimal method for the size of the screw conveyor components, but the helix angle of the auger screw blade can also choose other sizes in the range of 8°~15°; the pitch of ...

Embodiment 3

[0099] see figure 1 , figure 2 and Figure 13 , On the basis of Example 2, the tea brick pressing mechanism 3 includes a pre-press 305, a final press 306, a circulation platform 301, a pressing mold 304, a circulation power assembly and a demoulding mechanism 5; the pre-press 305 and the final press 306 All are placed on the top of the frame body 4; the pressing mold 304 is placed on the circulation platform 301 and is located below the pre-press 305 and the final press 306; the demoulding mechanism 5 is located below the circulation platform 301, and the demoulding mechanism 5 passes through the circulation platform 301 is connected with the pressing mold 304; the circulation platform 301 is connected; the circulation power assembly is placed under the circulation platform 301 and connected with the circulation platform 301, driving the pressing mold 304 on the circulation platform 301 to move, the circulation power assembly is connected with the electric control box 401, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com