Cutting and receiving system of a laser cutting machine

A laser cutting machine and cutting system technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of uneven transmission, insufficient rigidity, deviation of finished product shape and size, etc., and achieve stable transmission and cutting quality. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

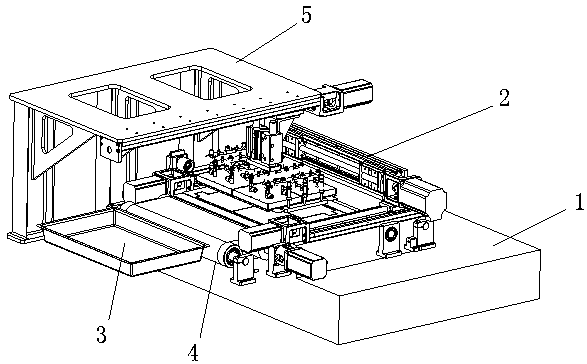

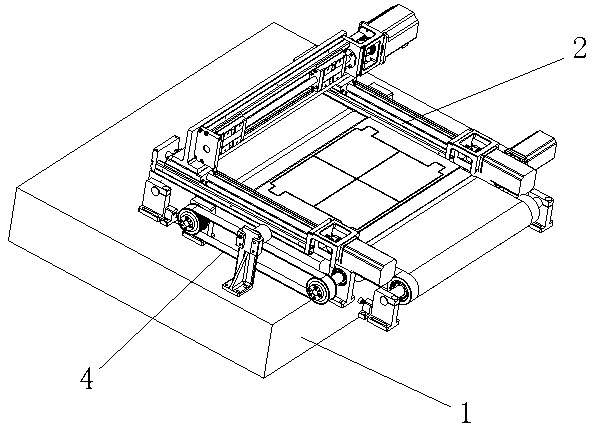

[0028] As shown in the figure, the cutting and receiving system of the laser cutting machine of this embodiment includes a base 1 provided with a cutting system 2, and a finished product tray 3 is provided on the side of the base 1, and the base 1 is placed on the side of the cutting system 2. A conveying unit 4 is provided below, and a reclaiming system 5 is provided above the cutting system 2. The cutting and receiving system of the laser cutting machine also includes a controller for controlling the conveying unit 4, the cutting system 2 and the reclaiming system 5 The key point is that the base 1 is also provided with a proximity switch for detecting whether there is a raw material tape in the cutting area; the controller is connected to the proximity switch (the controller and the proximity switch are not shown in the figure).

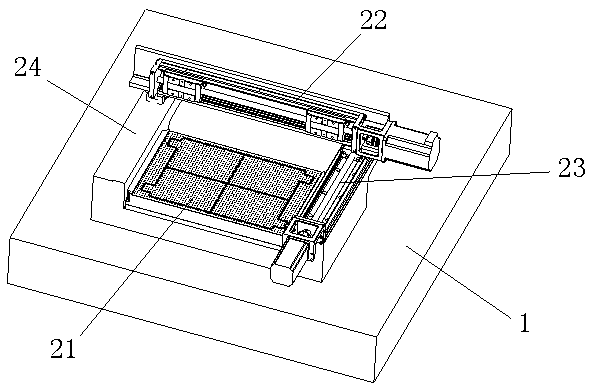

[0029] Specifically, the cutting system 2 includes a support, a moving cutting assembly mounted on the support 24, and an adsorption assembly 21. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com