Automatic simulation method for ethylene glycol regeneration and recovery system

A simulation method and recycling system technology, applied in the field of chemical process industry, can solve the problems of low design accuracy, low efficiency of ethylene glycol regeneration and recovery, and high cost, achieve high reusability and scalability, and save capital and operating costs. , the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to understand the content of the present invention more clearly, it will be described in detail with reference to the drawings and embodiments.

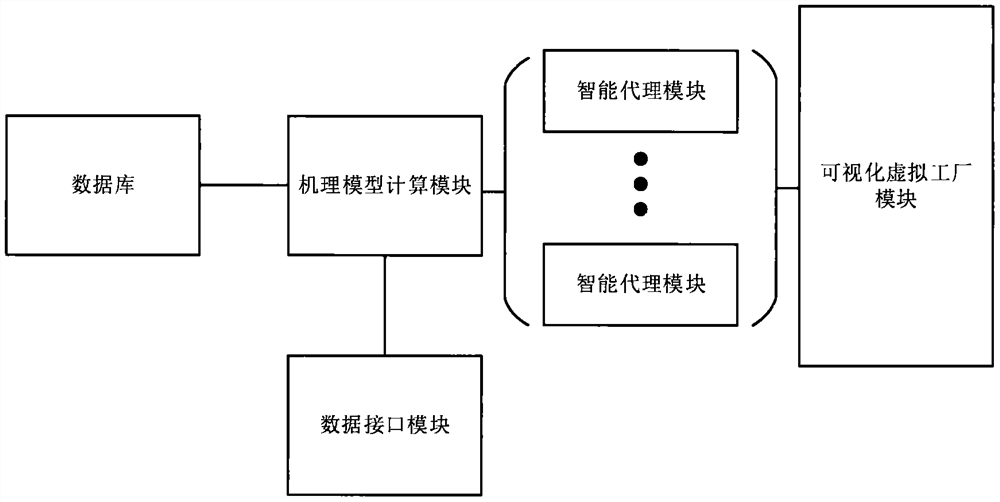

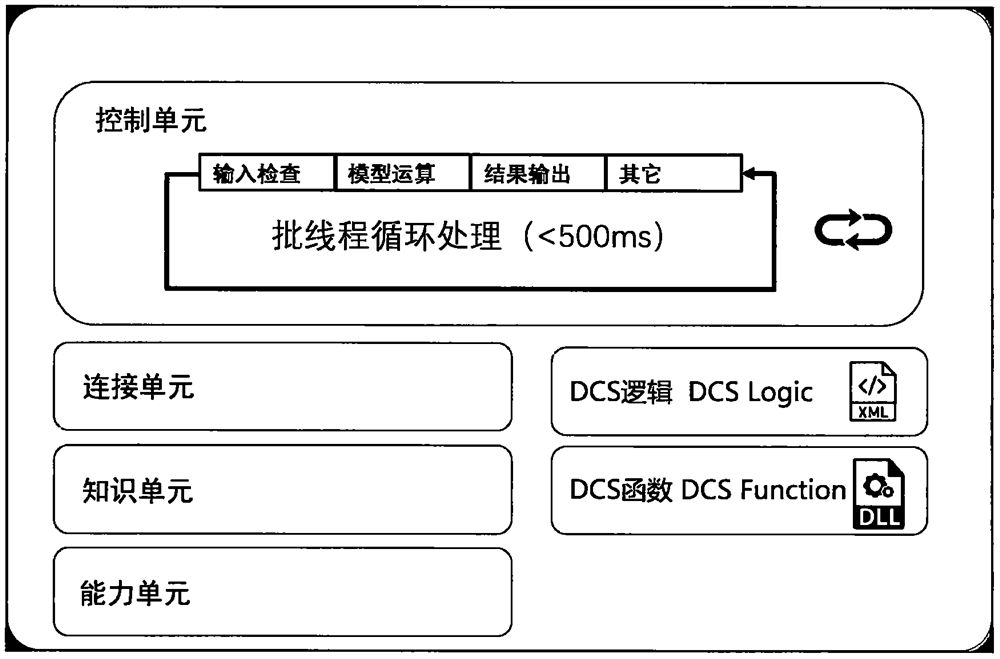

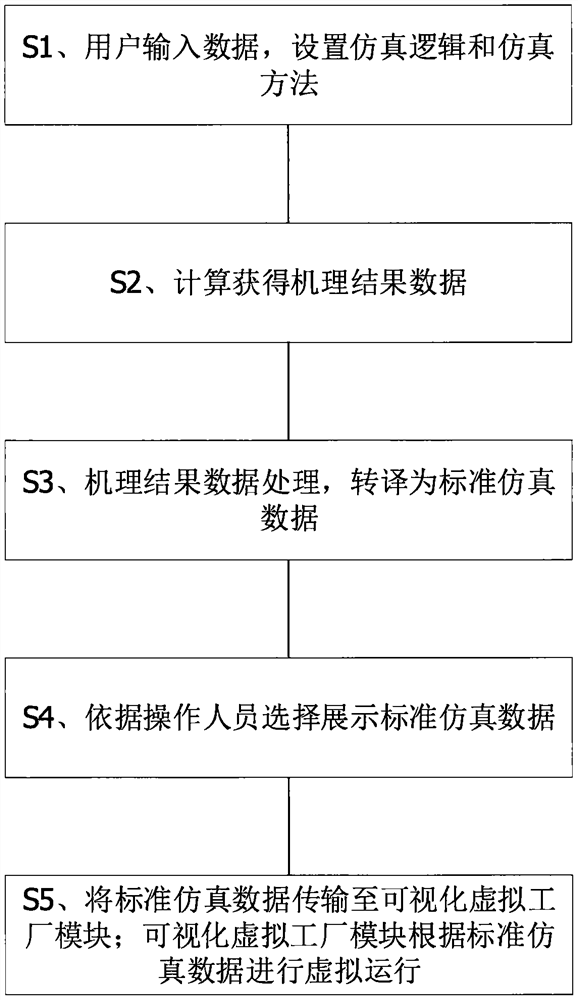

[0028] Such as figure 1 Shown is the schematic structural diagram of the ethylene glycol regeneration and recovery process simulation system of the present invention, including a database connected to each other, a mechanism model calculation module, a plurality of intelligent agent modules, and a data interface module; the database includes a physical property database, a thermodynamic algorithm library, and a unit An equipment model library and a numerical calculation method library; the mechanism model calculation module calculates the mechanism model according to the user input data received by the data interface module and calls the data in the database to obtain mechanism result data; the intelligent agent module includes a connection unit, SiLA translation unit, control unit, knowledge unit, capability unit, es...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com