Flapping rotor device with ascending shaft wing vertically operating and descending shaft wing horizontally operating

A flapping-rotor, horizontal technology, applied in the field of aircraft, can solve the problems of high cost, poor stability, difficult manufacturing and design, etc., and achieve the effects of reasonable design, convenient control and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention are described in detail below.

[0039] The invention discloses a flapping rotor device for vertical operation of upward shaft wings and downward horizontal operation, comprising:

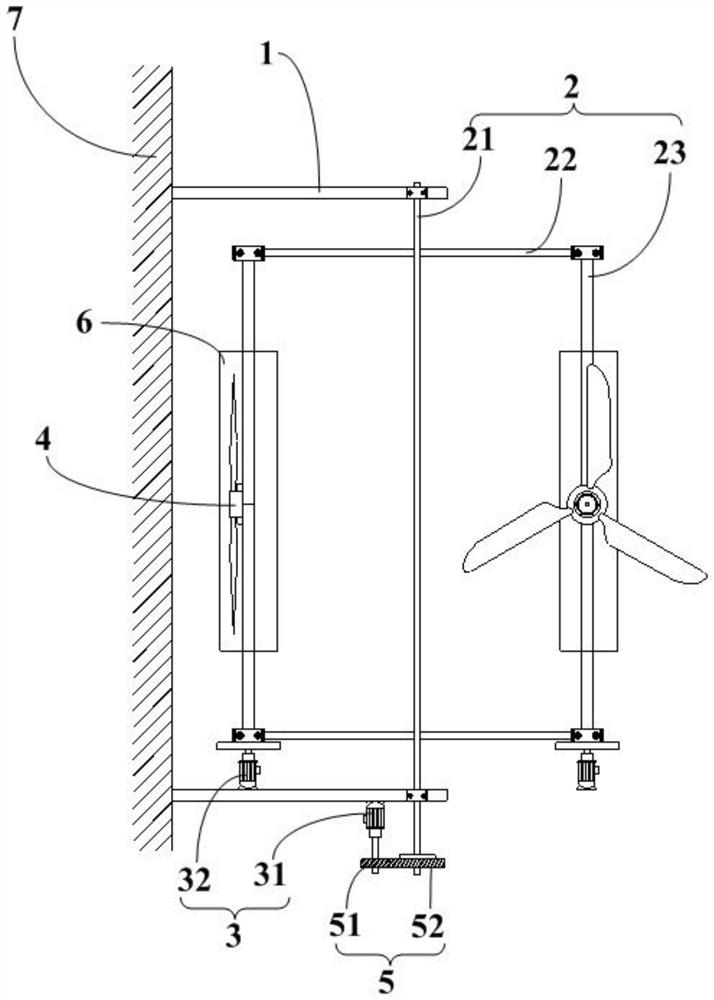

[0040] Support assembly 1, the support assembly 1 is arranged on the side wall of the fuselage 7, and is fixedly connected with the fuselage 7;

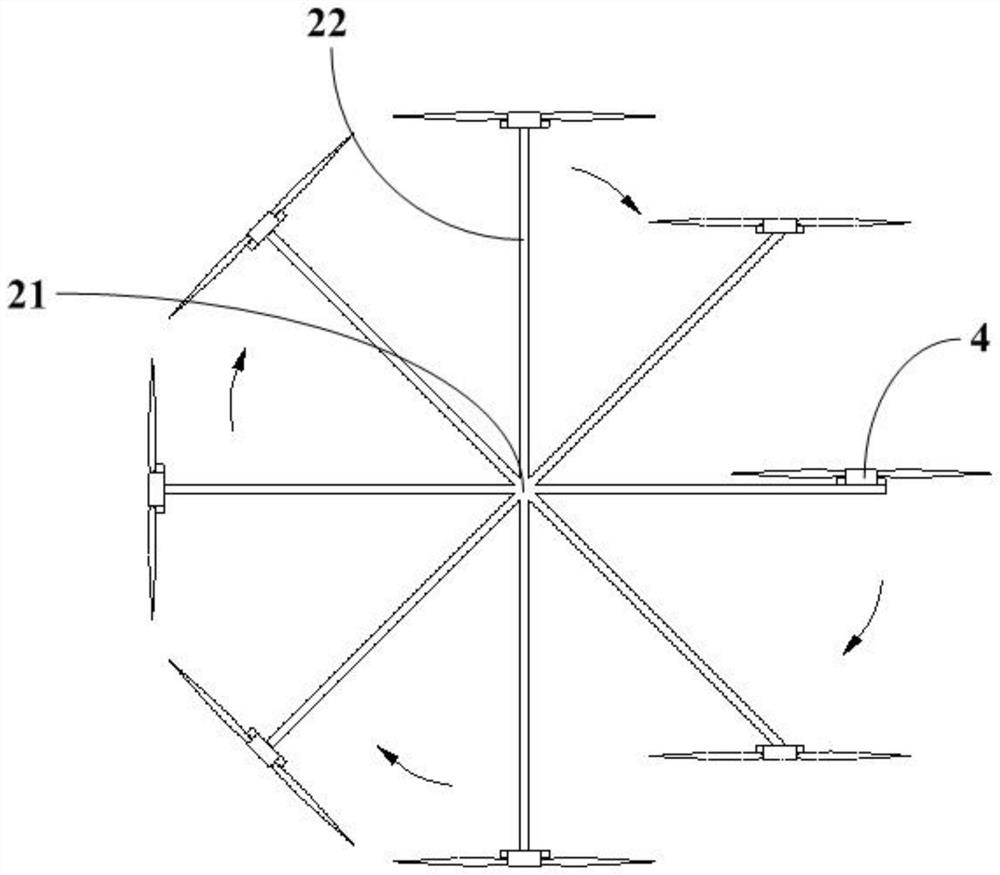

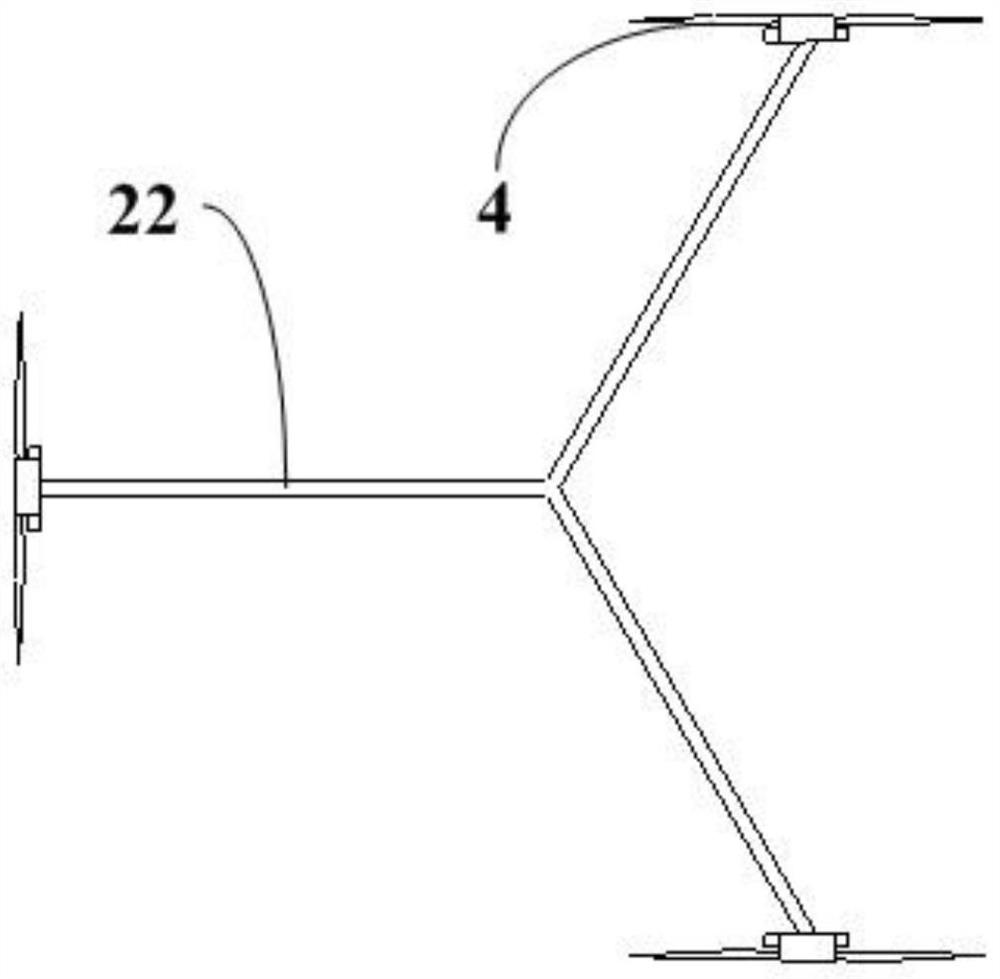

[0041] Rotation assembly 2, the rotation assembly 2 includes a revolution main shaft 21, a rotating arm 22 and an autorotation main shaft 23, the revolution main shaft 21 passes through the support assembly 1 and is rotatably connected with the support assembly 1; The rotation main shaft 23 passes through the other end of the rotating arm 22 and is perpendicular and rotatably connected to the rotating arm 22, and the revolution main shaft 21 and the axis of the rotation main shaft 23 are arranged in parallel;

[0042] Drive assembly 3, the drive assembly 3 includes a first drive motor 31 and a second drive moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com