Garment punching device with collecting function and using method thereof

A technology for punching equipment and clothing, applied in metal processing, etc., can solve the problems of not being able to guarantee the quality of clothing, affecting the accuracy of punching, affecting processing efficiency, etc., and achieve the effects of saving manpower for cleaning, ensuring quality, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

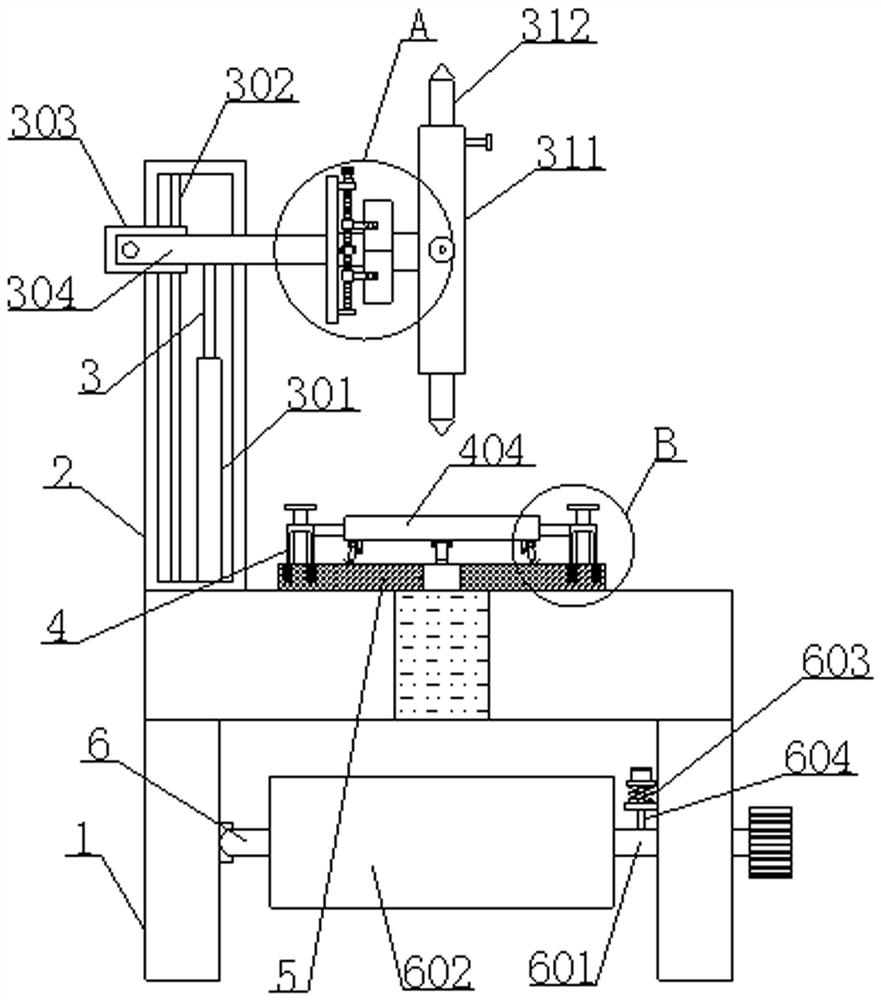

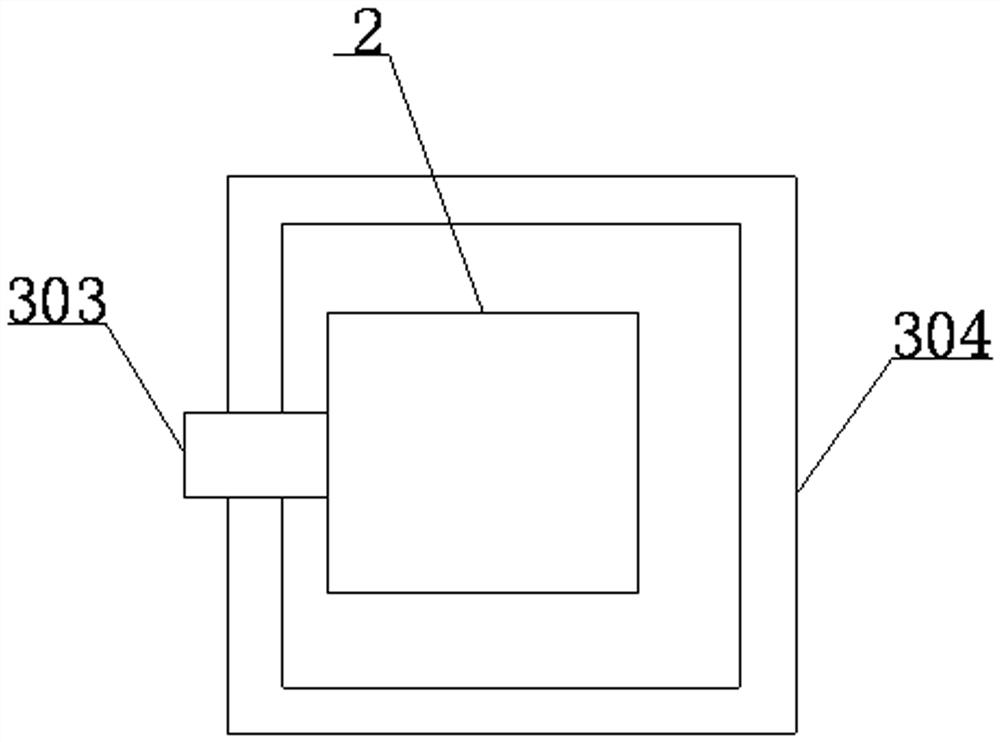

[0035] see Figure 1-7 , the present invention provides a technical solution: a clothing punching device with a collection function, including a base 1, a casing 2, a punching assembly 3, a forming assembly 4, a bottom plate 5 and a waste collection mechanism 6, and the top of the base 1 is fixedly installed There is a shell 2, the right side of the shell 2 is provided with a punching assembly 3, the top of the base 1 is fixedly installed with a base plate 5, the top of the base plate 5 is provided with a molding assembly 4, and the bottom of the base 1 is provided with a waste collection mechanism 6.

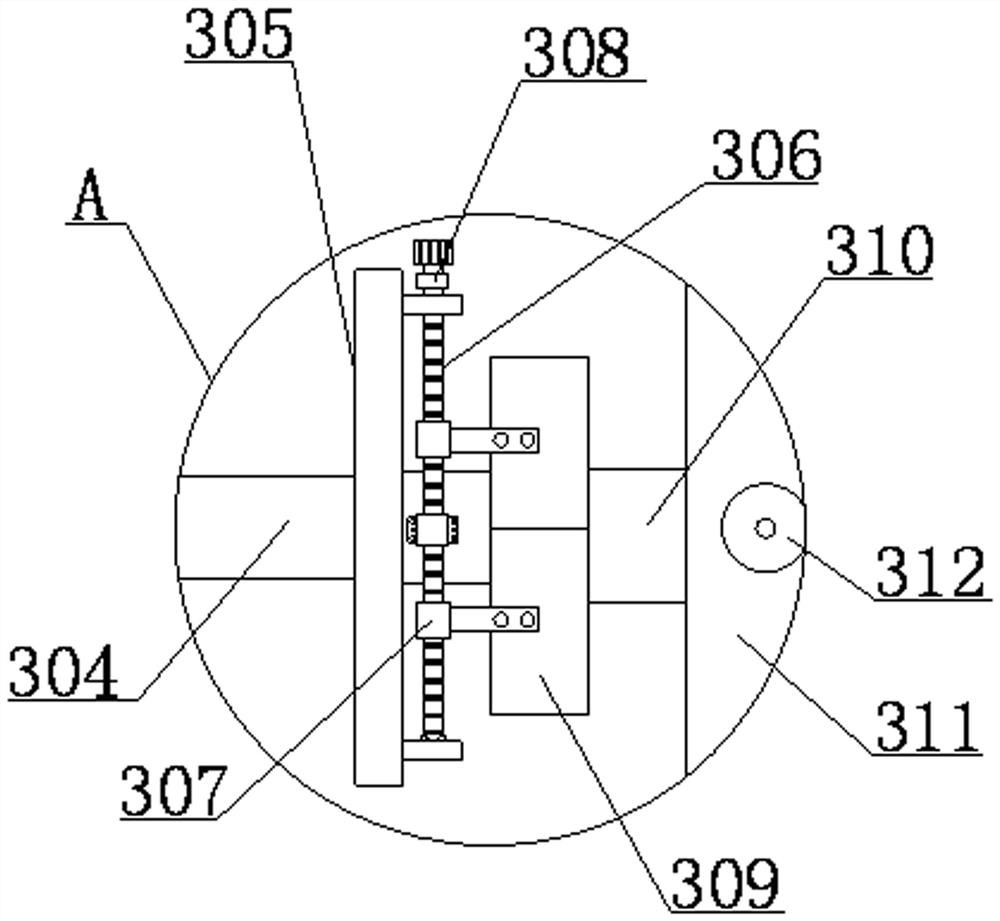

[0036] The punching assembly 3 includes a cylinder 301, a limit rod 302, a moving block 303, a connecting plate 304, a mounting plate 305, a driving screw 306, a connecting block 307, a driving wheel 308, a clip 309, a rotating rod 310, a cutter head 311, a cutter 312, fixed plate 313 and fixed screw rod 314, the inside of shell 2 is fixedly installed with cylinder 301, and the...

Embodiment 2

[0048] The inside of the cutter head 311 is fixedly equipped with a fixed plate 313, and the inside of the fixed plate 313 is movably connected with a fixed screw rod 314, and the cutter 312 is fixedly installed in the inside of the cutter head 311 by the fixed screw rod 314. When the cutter 312 needs to be installed and When disassembling, it is only necessary to rotate the fixing screw 314 to disengage from the cutter 312, and the cutter 312 can be taken out, and the operation is simple.

[0049] A method for using a garment punching device with a collection function, the steps are as follows:

[0050] 1. Place the position where the clothing needs to be punched on the surface of the bottom plate 5, and it is directly below the cutter 312. Turn the drive screw 306 to drive the clip 309 to separate. The tool 312 then reversely rotates the drive screw 306 to drive the clip 309 to fix the rotating rod 310 .

[0051] 2. Then the cylinder 301 drives the cutter 312 to descend to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com