Metal cutting tool convenient to disassemble and assemble

A technology for metal cutting and easy disassembly and assembly. It is applied in the direction of metal processing equipment, metal processing machinery parts, milling cutters, etc. It can solve the problems of cumbersome disassembly and assembly, and achieve the effects of short disassembly and assembly time, simple structure and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

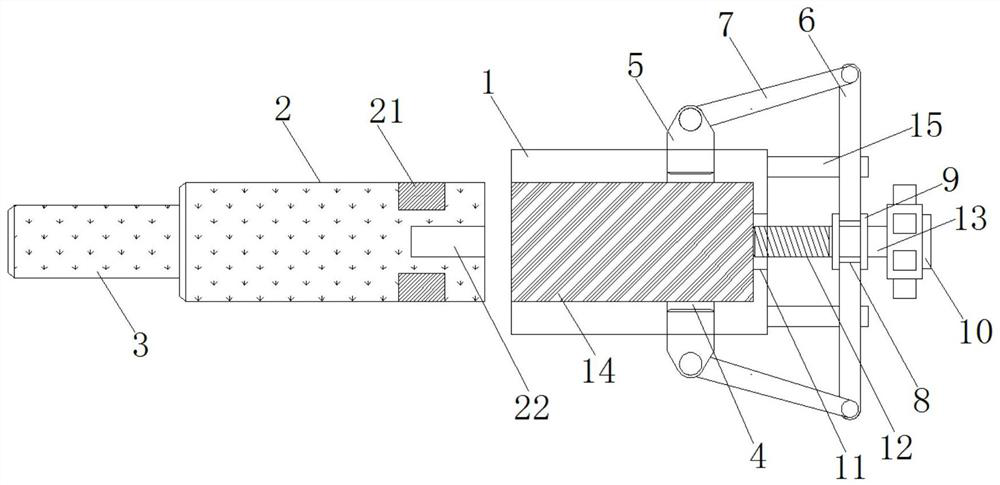

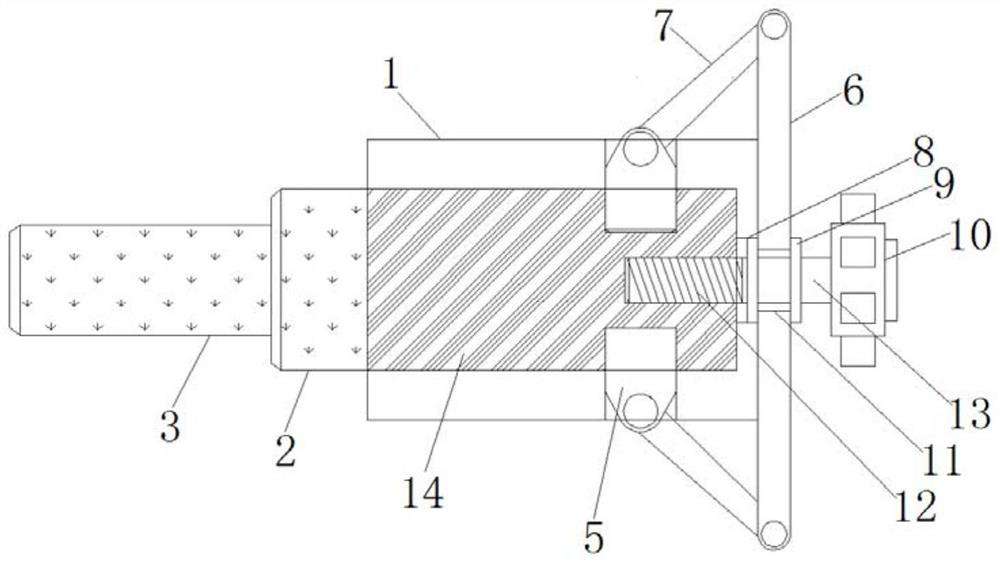

[0017] Embodiment 1, during installation, the knife handle 2 is inserted into the installation groove 14, and the locking groove 21 is located on one side of the slider 5. After the handle 10 is rotated, the rotating rod 13 and the screw rod 12 rotate simultaneously, and the screw rod 12 is screwed into the screw hole 22, the rotating rod 13 rotates in the through hole 8. Since the screw rod 12 is displaced when it rotates, the rotating rod 13 rigidly connected with it also moves at the same time, and the baffle plate 9 pushes the push plate 6 when moving with the rotating rod 13. Slide on the guide rod 15, the connecting rod 7 on both sides is forced to rotate, and the other end pushes the slider 5 to slide in the middle. When the screw rod 12 is fully tightened, the slider 5 just slides to the inside of the locking groove 21, and the knife The handle 2 is clamped tightly, and at this time the push plate 6 is tightly attached to the end of the mounting seat 1, as figure 2 As...

Embodiment 2

[0018] Embodiment 2, when dismounting, the personnel rotates the handle 10 in the opposite direction, the screw rod 12 gradually selects the inside of the screw hole 22, the baffle plate 9 on the other side pulls the push plate 6 to reset, and the limit block acts to limit the stroke of the push plate 6 Purpose, when the push plate 6 is in contact with the limit block, the slider 5 is pulled out from the inside of the locking groove 21, and the handle 2 can be removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com