A kind of box girder end face spraying device and spraying method

A spraying device and end face technology, which is applied in the field of box girder end face spraying devices, can solve problems such as low construction efficiency, heavy workload, and health hazards of personnel, and achieve the effects of improving operating efficiency, avoiding waste, and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

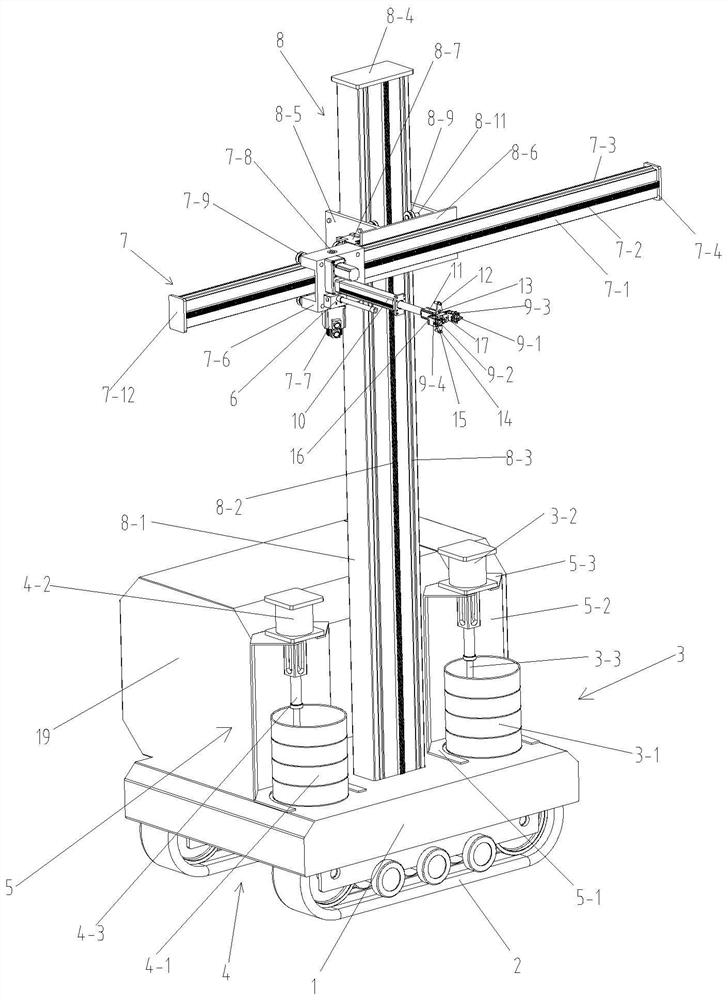

[0115] The control module includes a box, a controller 18 arranged in the box, and a wireless wireless connection with the controller 18.

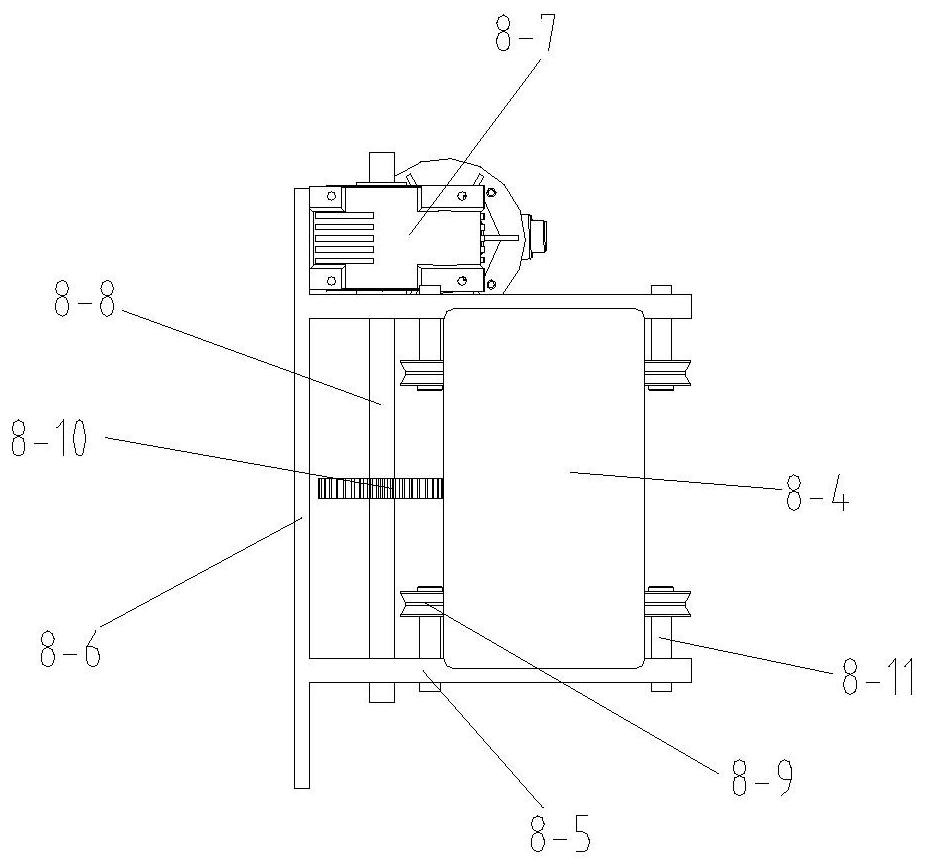

[0117] The output shaft of the lift motor 8-7 is connected with a lift drive shaft 8-8, and the lift drive shaft 8-8 is provided with

[0118] In this embodiment, the lift seat is provided with a lift guide member, and the lift guide member includes a

[0121] As shown in Figure 4, in this embodiment, an air compressor 19 is provided on the vehicle body 1;

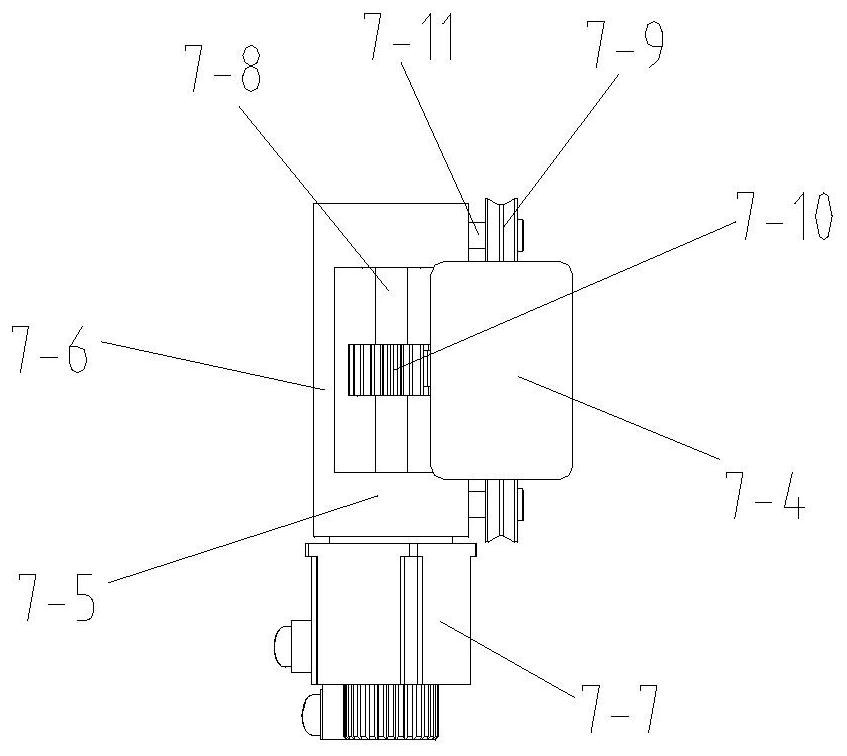

[0122] The sprinkler mechanism comprises a mounting plate 16, a first sprinkler seat 9-3 and a second sprinkler seat arranged on the mounting plate 16

[0124] In this embodiment, it should be noted that the box body is arranged on the vehicle body 1 .

[0127] In the present embodiment, the feeding mechanism is provided, in order to transport the waterproof coating to the nozzle mechanism through the feeding mechanism,

[0133] In this embodiment, the vertical plate 8-5 is provided with a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com