Ultra-wide high-lift synchronous steering insecticide spraying machine rack

A medicine sprayer and frame technology, which is applied to the device for catching or killing insects, application, animal husbandry, etc., can solve the problems of limited lifting height of hydraulic cylinders, inconvenient agricultural production, and difficulty in maintaining balance, so as to improve the use efficiency, The effect of reducing damage to crops and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

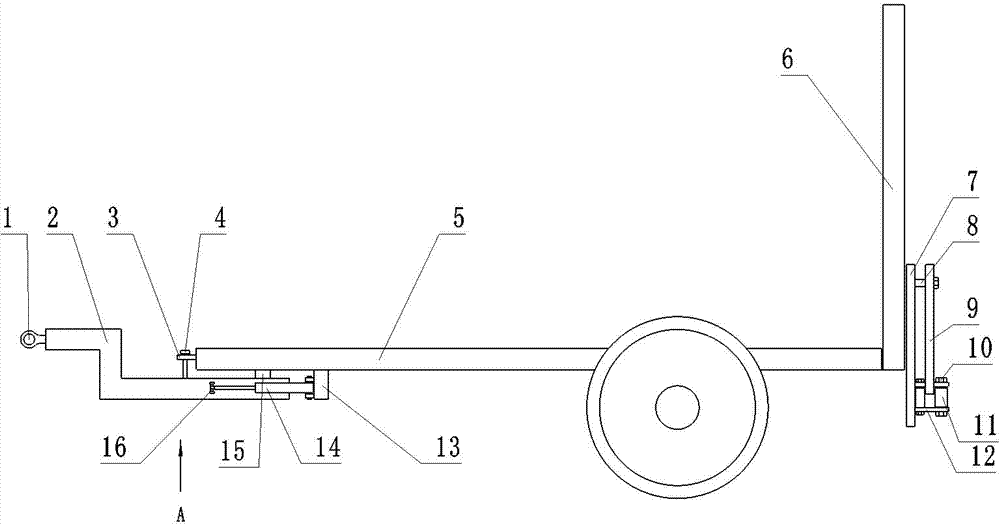

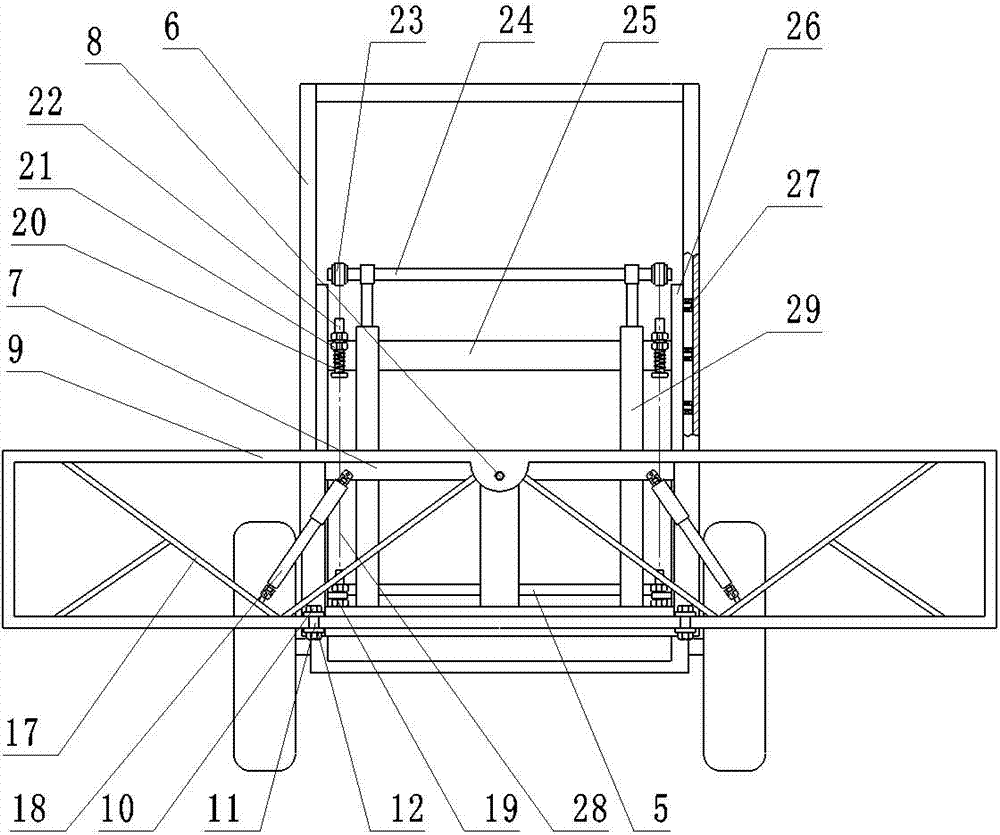

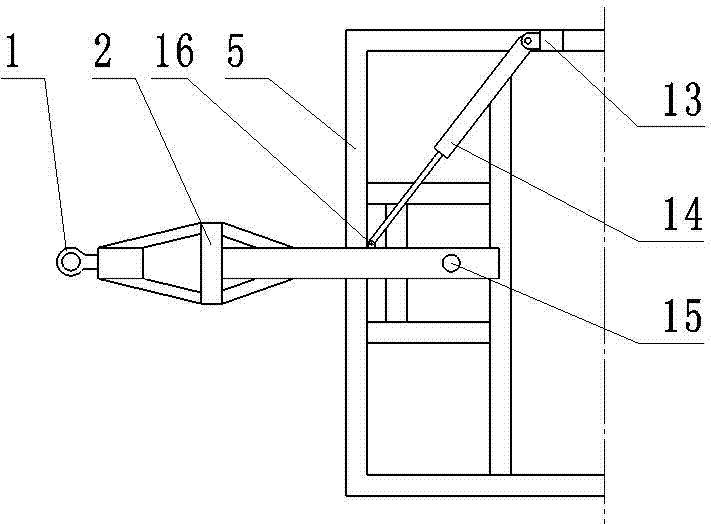

[0020] Example 1: refer to Figure 1 to Figure 5 , is the structural representation of embodiment 1 of the present invention, and the front end of frame body 5 is connected with L-shaped draw frame 2 through draw frame twisted shaft 15, and the front end of L-shaped draw frame 2 is provided with the traction ring 1 that connects tractor, on machine The side of the frame body 5 is provided with a steering cylinder seat 13 connected to the steering cylinder 14, and the other end of the steering cylinder 14 is connected to the side of the L-shaped traction frame 2 through the steering cylinder hinge shaft 16, and the steering cylinder 14 communicates with the steering cylinder of the tractor front wheel. , when the tractor is turning, the wheels on the frame body 5 can be turned synchronously with the front wheels of the tractor, so that the turning radius of the entire sprayer is the smallest, and the purpose of the sprayer to minimize damage to crops when turning is realized. ...

Embodiment 2

[0021] Example 2: refer to Figure 6 , is a schematic diagram of the structure of Embodiment 2 of the present invention. Compared with Embodiment 1, the difference between Embodiment 2 and Embodiment 1 is that in Embodiment 2, in order to better buffer the swing of the spray frame 9 from left to right, in the position limit The top of the plate 12 is provided with a hinge 30, one end of the balance oil cylinder 31 is hinged with the hinge 30, and the other end passes through the hole 33 arranged in the middle of the bottom end of the bracket 7, and springs are arranged on the balance oil cylinder 31 on both sides of the hole 33. The stopper 34 is provided with a balance spring 32 between the hole 33 and the spring stopper 34, which can further buffer the left and right swing of the spray rack 9, and can also adjust the balance oil cylinder 31 when the sprayer loses balance in uneven farmland. Balance the extra wide spray rack 9.

Embodiment 3

[0022] Example 3: refer to Figure 7 , is a structural schematic diagram of Embodiment 3 of the present invention. Compared with Embodiment 2, the difference between Embodiment 3 and Embodiment 2 is that two shock absorbers 18 are arranged on each side in Embodiment 3, which can be more Good buffer spray frame 9 swings left and right.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com