Brush head and manufacturing method thereof

A manufacturing method and bristle technology, which can be applied to brushes, brush bodies, bristles, etc., can solve the problems of easy residual stains, reduced cleaning effect of bristles, and hair loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

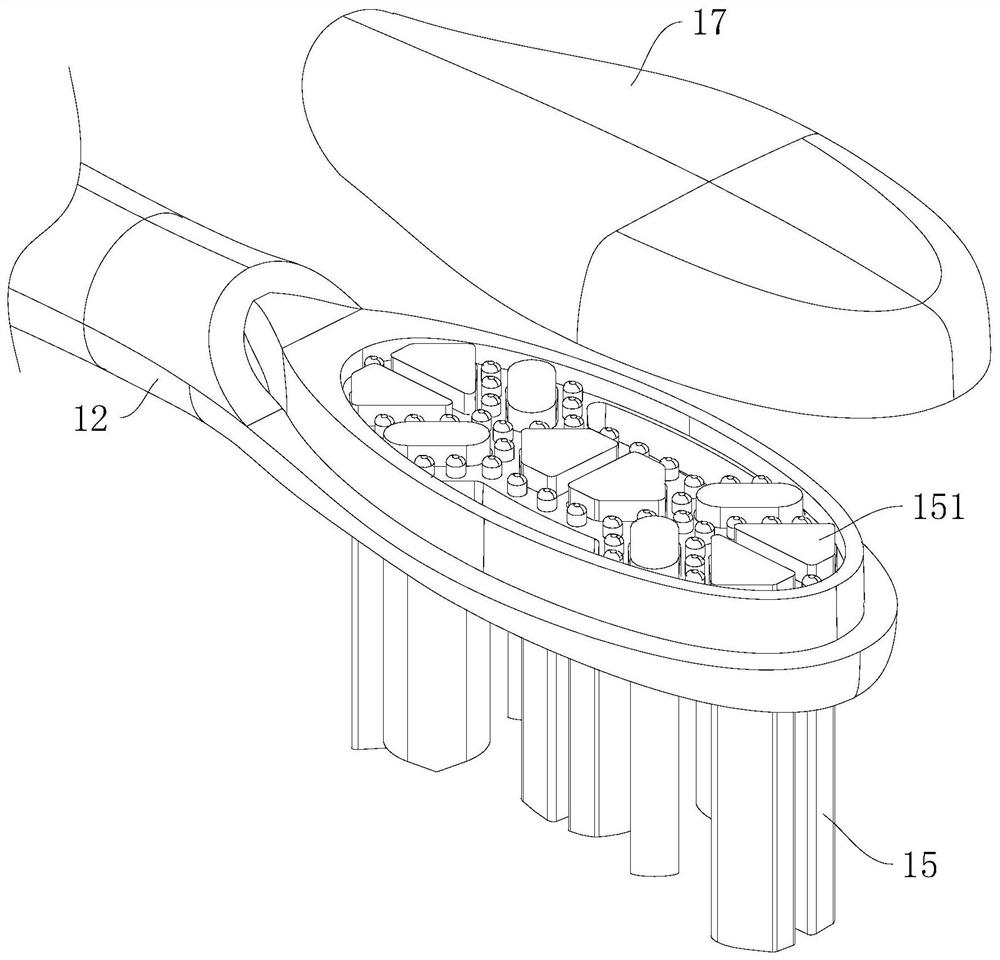

[0039] See figure 1 , figure 1 The brush head 10 provided for the first embodiment of the present invention is applied to the structure of the toothbrush 100.

[0040]The first embodiment of the present invention provides a brush head 10 having a non-residual stain, facilitating cleaning, and brush 15 is more stable. The brush head 10 can be applied to a toothbrush 100 and a cleaning brush, etc., of course, the brush head 10 can also be used independently.

[0041] Among them, the brush head 10 is applied to the toothbrush 100 as an example, the toothbrush 100 includes the above-described brush head 10 to improve the tidy of the toothbrush 100, of course, the toothbrush 100 can also include a brush rod 20, the brush head 10 is connected to the brush rod 20, the strip 20 is used to hold the user to facilitate use.

[0042] Further, the toothbrush 100 can also include a driving member 30, which can be mounted to the brush rod 20, and can be moved to the brush head 10, for example,...

no. 2 example

[0072] See Figure 6 , Figure 6 A flow diagram of a brush head manufacturing method provided in the second embodiment of the present invention.

[0073] The brush head manufacturing method is used to make the brush head 10 provided by the first embodiment of the present invention, and it is to be noted that the brush head manufacturing method provided in the present embodiment, the basic principles and the resulting technical effects are the same, and the above embodiments. For a brief description, this embodiment is not mentioned, and the corresponding content can be referred to in the above embodiment.

[0074] The brush head manufacturing method includes:

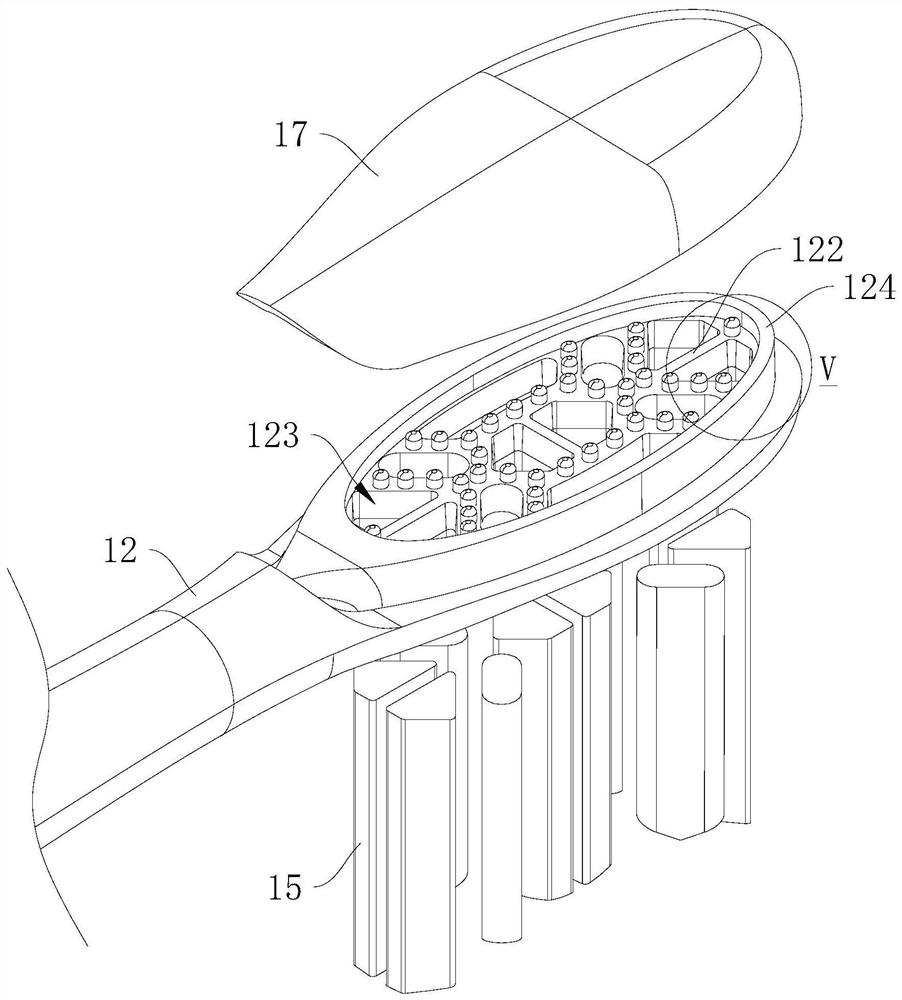

[0075] Step S101: Wearing bristles 15 in connection through holes 123, and partially protrudes over the fixing surface 122. A bristles 151 are formed in the fixing surface 122.

[0076] Step S102: The melt connects the fixing surface 122 and the bristles 151, and forms a molten coupling piece 152 covering the fixing surface 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com