Oat beverage with low glucose content and preparation method of oat beverage

A low-glucose and glucose technology, applied in the field of vegetable protein processing, can solve problems such as unfavorable processing, and achieve the effects of guaranteed quality, pure flavor and low glycemic index.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the oatmeal beverage of the present invention may comprise the following steps:

[0033] S1. Cleaning of oatmeal: Naturally ripened or matured oatmeal grains are cleaned and drained for later use without any treatment;

[0034] S2. Oat cooking: cook oat grains: water=1:6.5-8 at 60-70°C for 5-20 minutes to kill the oxidase in oats; based on 1000 parts by weight of finished product, the raw materials include 80-130 parts by weight oat grains of 80-160 parts by weight, or oat flour of 80-160 parts by weight.

[0035] S3. Refining oats; refining the oat grains after softening; preferably, homogenizing the oat pulp;

[0036] S4 Enzymolysis of oat pulp: first heat oat pulp to 60-65°C, add liquefaction enzyme and glucoamylase for 30-60 minutes, for example, 45-50 minutes; add glucose invertase and xylose for enzymolysis, enzymolysis The time is 5-15 minutes, such as 10 minutes;

[0037] The combined ratio of liquefaction enzyme, glucoamylase, gluco...

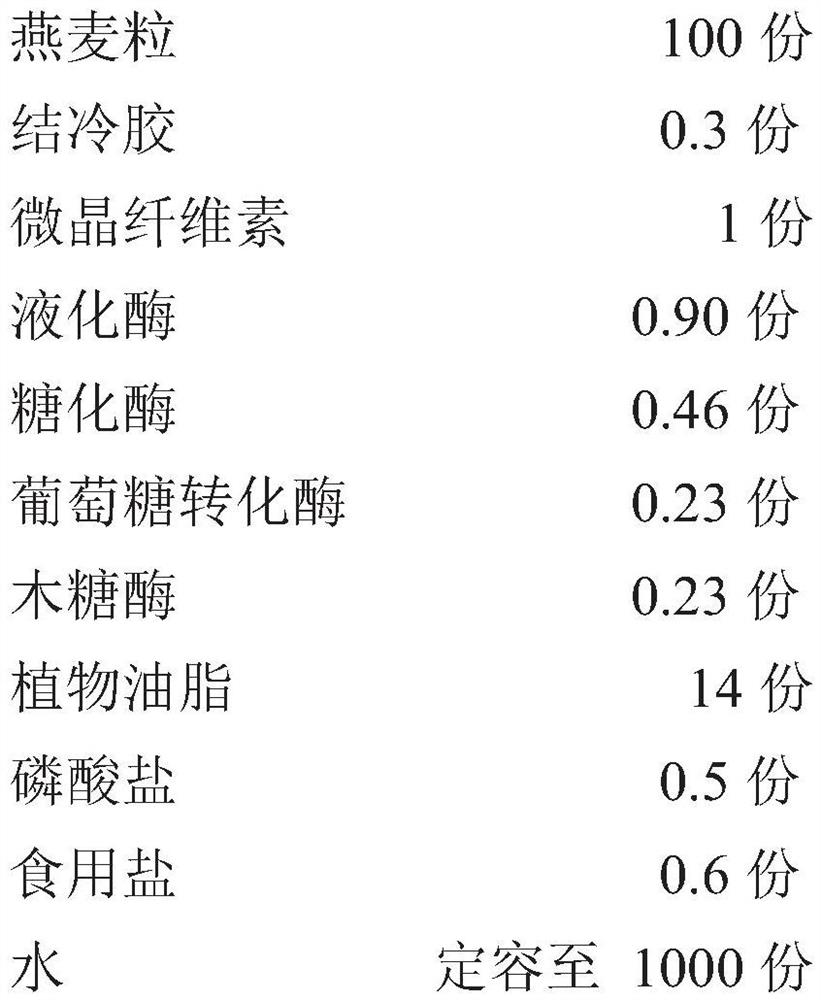

Embodiment 1

[0053] Based on 1000 kg of finished product, the raw materials include;

[0054]

[0055] The preparation method comprises the following steps:

[0056] 1. Oat grain processing:

[0057] Wash the fresh oat grains with water, and drain the water;

[0058] According to the ratio of oat grains: water = 1:7, oat grain water is made, the temperature is raised to 65-68 ° C, and boiled for 5 minutes;

[0059] 2. Refining oat grains; fully refine the oat grains; use three-stage grinding equipment for refining treatment; according to the pH value, you can use edible baking soda to adjust the pH value of the oat pulp to 6.2;

[0060] 3. Enzymatic hydrolysis of oat pulp: raise the temperature of oat pulp to 60-65°C, when the viscosity of oat pulp reaches the maximum value, add medium-temperature amylase, glucoamylase, glucose invertase, and xylose to hydrolyze for 50 minutes;

[0061] 4. Enzyme activity inactivation; raise the temperature of the enzymolysis solution to 90-95°C for ...

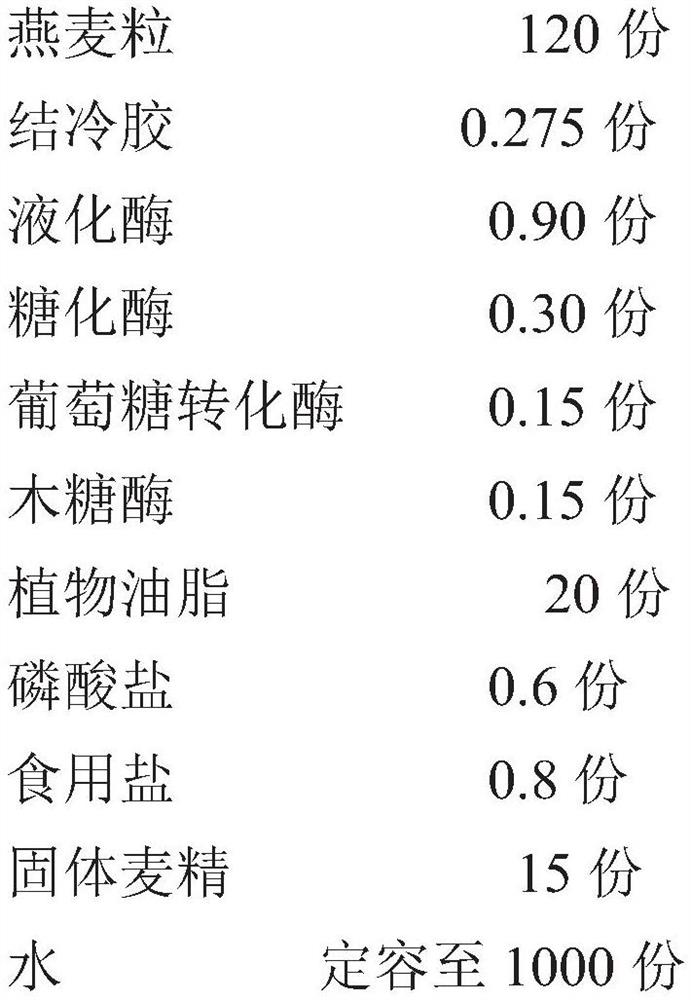

Embodiment 2

[0070] Based on 1000 kg of finished product, the raw materials include;

[0071]

[0072] The preparation method comprises the following steps:

[0073] 1. Oat grain processing:

[0074] Wash the fresh oat grains with water, and drain the water;

[0075] According to the ratio of oat grains: water = 1°C7, make oat grain water, raise the temperature to 65-68°C, and cook for 5 minutes;

[0076] 2. Refining oat grains; fully refining oat grains; using three-stage grinding equipment for refining treatment; using edible baking soda to adjust the pH value of oat pulp to 7.2;

[0077] 3. Enzymatic hydrolysis of oat pulp: raise the temperature of oat pulp to 60-65°C, when the viscosity of oat pulp reaches the maximum value, add liquefaction enzyme and glucoamylase for enzymatic hydrolysis for 40 minutes; solution for 10 minutes;

[0078] 4. Enzyme activity inactivation; raise the temperature of the enzymolysis solution to 90-95°C for 15 minutes;

[0079] 5. Separation and slag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com