System and method for improving power plant operation on-duty monitoring efficiency

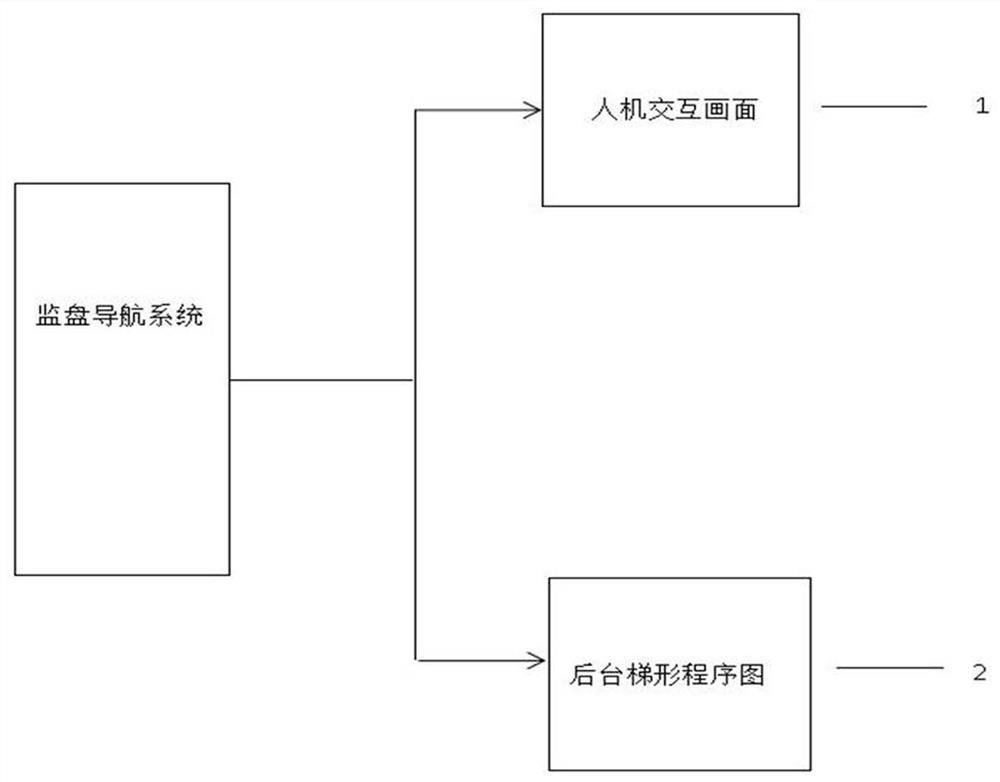

A technology for power plants and monitoring systems, applied in the field of power systems, can solve problems such as the inability to quickly grasp the key points of monitoring, the inability to effectively control the dynamic monitoring efficiency of the on-duty personnel, and the inability of the on-duty personnel to ensure the monitoring efficiency for a long time. The effect of improving the quality of supervision, improving the quality of supervision, and standardizing the work of supervision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

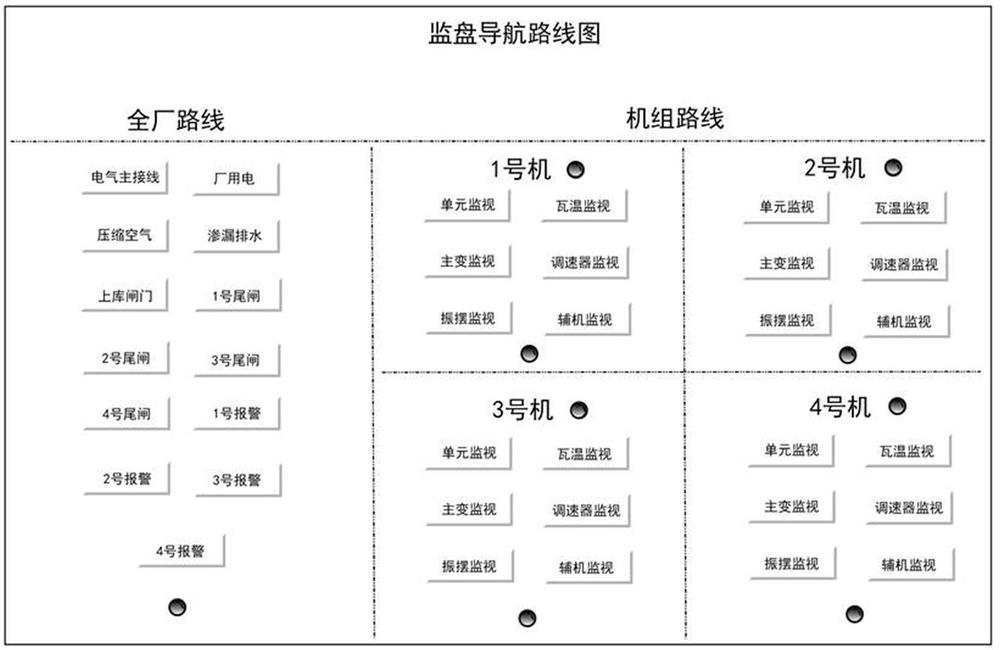

[0031] Such as figure 2 As shown, first click the Shift button, wait for the button to appear red and then follow the figure 2 The state inspection route of the public equipment in the whole plant conducts inspection and inspection of each screen. If all the route screens are inspected and the inspection button is clicked, it means that the inspection of the state of the public equipment in the whole plant is completed.

[0032] For the running units, the monitoring system will broadcast voice prompts every 40 minutes, and the monitoring system message will display "unit * is running, please perform screen inspection". When inspecting the status of the unit's operating equipment, such as figure 2 The equipment status inspection route of the medium unit is inspected.

Embodiment 2

[0034] Managers can regularly inquire and check the monitoring record report of the personnel on duty to confirm the quality of the monitoring of the corresponding shift personnel, including the number of route inspections, the duration of screen stay, etc., so that managers can correct problems in a timely manner.

Embodiment 3

[0036] Such as image 3 and 5 As shown, according to the requirements of the monitoring and navigation system, a plant-wide equipment inspection is required before and after each shift. Therefore, after the shift button DUMMY_DI[20] is pressed, if the specified 13 screen inspection points are all ON, it will output the operation status of the whole factory equipment. DUMMY_DI[18] is completed. When DUMMY_DI[18] is activated, the inspection points of 13 screens will be cleared immediately. At the same time, DUMMY_DI[18] will automatically reset after 60 seconds. If the succession button is OFF , all intermediate signal points are cleared, that is, the equipment status inspection of the whole plant is completed, and the inspection indicator light is red.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com