Packaging equipment for thick-film chip resistor

A chip resistor and packaging equipment technology, which is applied in the manufacture of encapsulated/cased resistors, etc., can solve the problem of inability to package two chip resistors, and achieve the effect of improving reliability and avoiding mutual friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

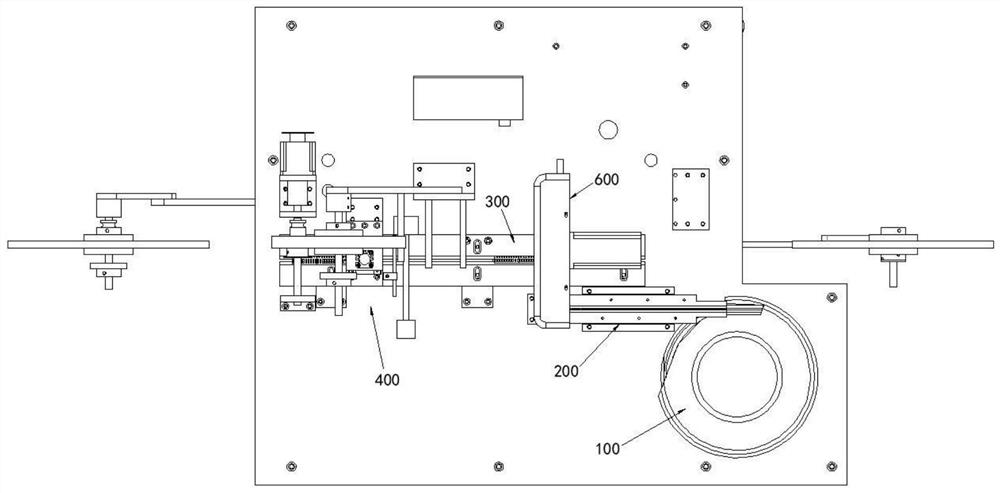

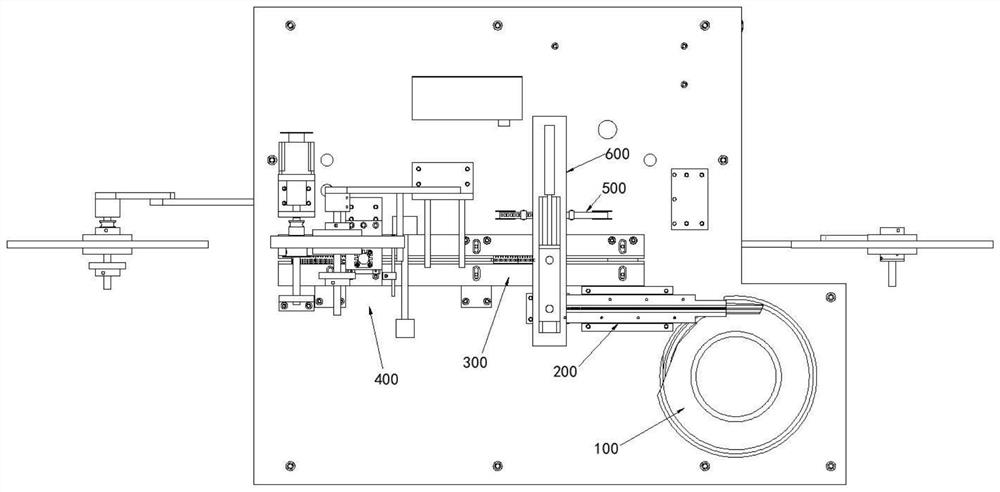

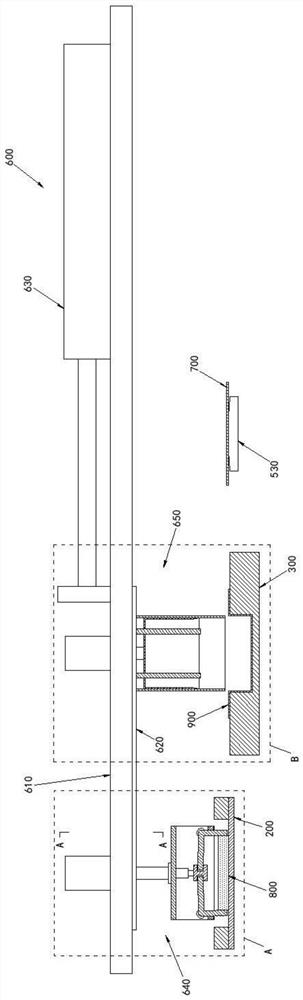

[0041] Such as Figure 2 to Figure 7 As shown, the packaging equipment for thick film chip resistors in this embodiment includes a vibration plate 100, a resistance track 200, a carrier track 300, a packaging mechanism 400, a film conveying assembly 500 and a manipulator 600;

[0042] The vibrating plate 100 is connected to the resistance track 200, the resistance track 200 and the film conveying assembly 500 are respectively located on both sides of the carrier track 300, the resistance track 200 is parallel to the carrier track 300, and the packaging mechanism 400 is installed on the carrier track 300; in this embodiment The vibrating plate 100, resistance track 200, carrier tape track 300 and packaging mechanism 400 involved are consistent with the prior art;

[0043] Such as Figure 8 with Figure 9 As shown, the film conveying assembly 500 includes a driving roller 510, a driven roller 520, a backing plate 530 and two sets of guide rollers 540, the film roll is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com