Method and system for determining segmented double-combustion quick-charge explosive combustion surface of solid rocket engine

A technology for solid rockets and deterministic methods, applied in special data processing applications, geometric CAD, design optimization/simulation, etc., can solve problems such as poor versatility and large amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

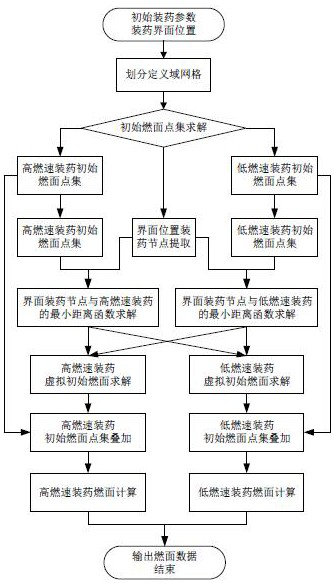

[0100] refer to figure 2 , a method for determining the combustion surface of solid rocket motor charge with segmented dual combustion rates, including:

[0101] In step S1, the three-dimensional configuration of the initial charge of the engine and the axial position Z of the interface between high and low burning rates are given.

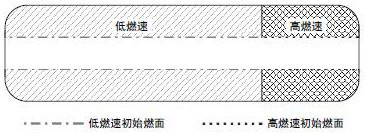

[0102] In the three-dimensional configuration of the initial charge of the engine, the part where the axial position coordinate is smaller than Z is the low burning rate charge area , the part where the axial position coordinate is larger than Z is the high burning rate charge area .

[0103] Step S2, divide the cube containing the initial three-dimensional configuration of the entire engine into a grid in Cartesian coordinates, and determine the attributes of each grid. If the grid only contains the three-dimensional configuration of the initial charge, then the grid is Charge node, if the mesh does not contain the initial three-dimensional...

Embodiment 3

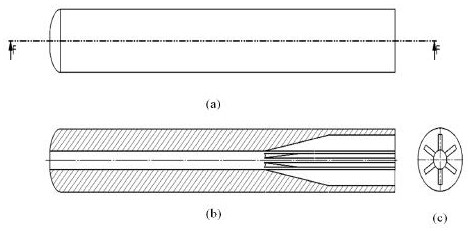

[0121] In this embodiment, the given three-dimensional configuration of the initial charge of the engine is as image 3 As shown, the interface between high and low burning rate is in the cylindrical section, Z=0.5, the burning rate ratio of high and low burning rate charges λ= 2.

[0122] When the interface between high and low burning rate is in the cylindrical section, the combustion of high burning rate charge will lead to exposure of the side of low burning rate charge, which will affect the change law of burning surface of low burning rate charge. When adopting the method for determining the burning surface of solid rocket motor segmented double-burning-velocity charges provided in Embodiment 1 of the present invention, there is always ,therefore , indicating that the low burning rate has no effect on the high burning rate, so the corresponding part can be omitted in the solution process, and only the influence of the high burning rate charge combustion on the low b...

Embodiment 4

[0127] In this embodiment, the given three-dimensional configuration of the initial charge of the engine is as image 3 As shown, the high- and low-burning-velocity interface is in the equal-section wing slot section, Z=1.2, and the burning-velocity ratio of high- and low-burning-velocity charges λ= 2.

[0128] When the interface between high and low burning rates is in the wing slot section of equal cross-section, there is no analytical solution, and the solid rocket motor segmented dual burning rate device provided by the present invention can be determined by checking whether the combustion process at the interface is matched or not. The effectiveness of the method for determining the combustion surface of the drug was verified. Similar to the high- and low-burning-velocity interface in the cylindrical segment, when the high- and low-burning-velocity interface is in the equal-section wing slot, there is still ,therefore , that is, the low burning rate has no effect on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com