Device for measuring deformation quantity of electrostrictive material based on Fabry-Perot cavity

A technology of electrostrictive materials and measuring devices, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of poor measurement stability, low measurement efficiency, small measurement range, etc., and achieve high precision, strong anti-interference ability, Make simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

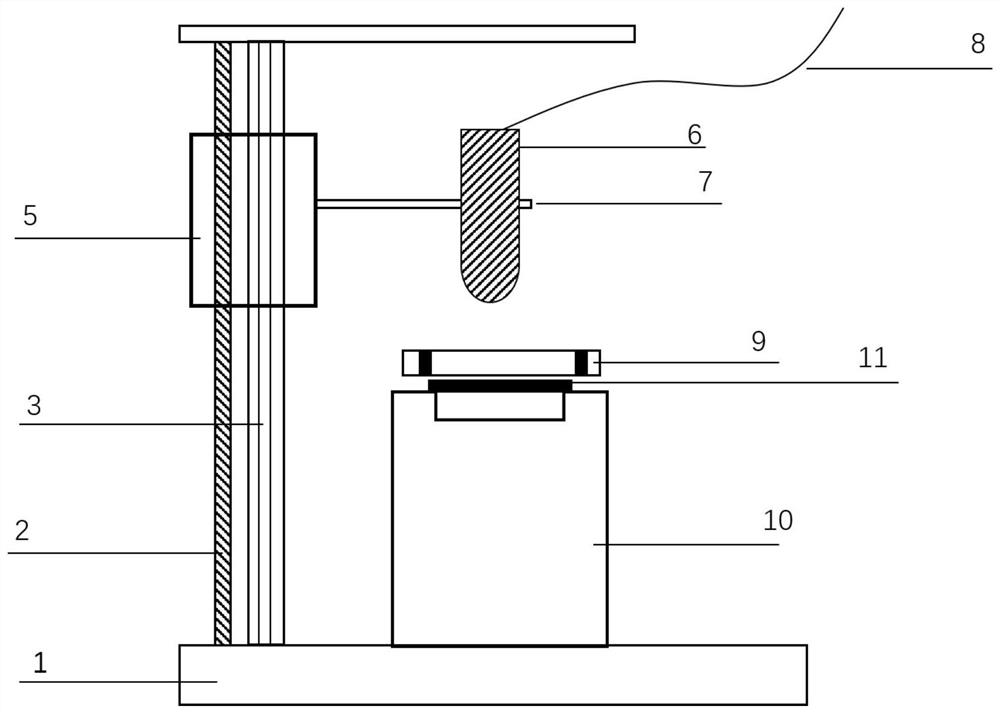

[0023] Such as Figure 1-2 As shown, a measuring device based on the deformation of the electrostrictive material in the Fappel cavity, including a base 1, a ball screw 2, a guide rail 3, a lifting controller 4, a slider 5, an optical probe 6, a fixing device 7, and an external lead Optical fiber 8, material fixture 9, material test bench 10, piezoelectric film 11; among them, the ball screw 2 and the guide rail 3 are vertically fixed on the base 1 respectively, and the two are connected by the slider 5; the fixed ball screw 2 passes through The stepping motor is connected with the lifting controller 4 to control the up and down movement of the slider 5; a material testing platform 10 is arranged on the base 1; a material fixture 9 is arranged above the material testing platform 10, and the material fixture 9 can be placed on the material testing p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com