High-rise building construction system and mounting and using method thereof

A technology of high-rise buildings and subsystems, applied in the field of high-rise building construction systems and their installation and use, can solve problems such as construction site confusion, worker shortage, and difficulty in unified scheduling, and achieve the goals of improving work efficiency, reducing operators, and improving the working environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0179] This embodiment provides a high-rise building construction system used for high-rise building construction.

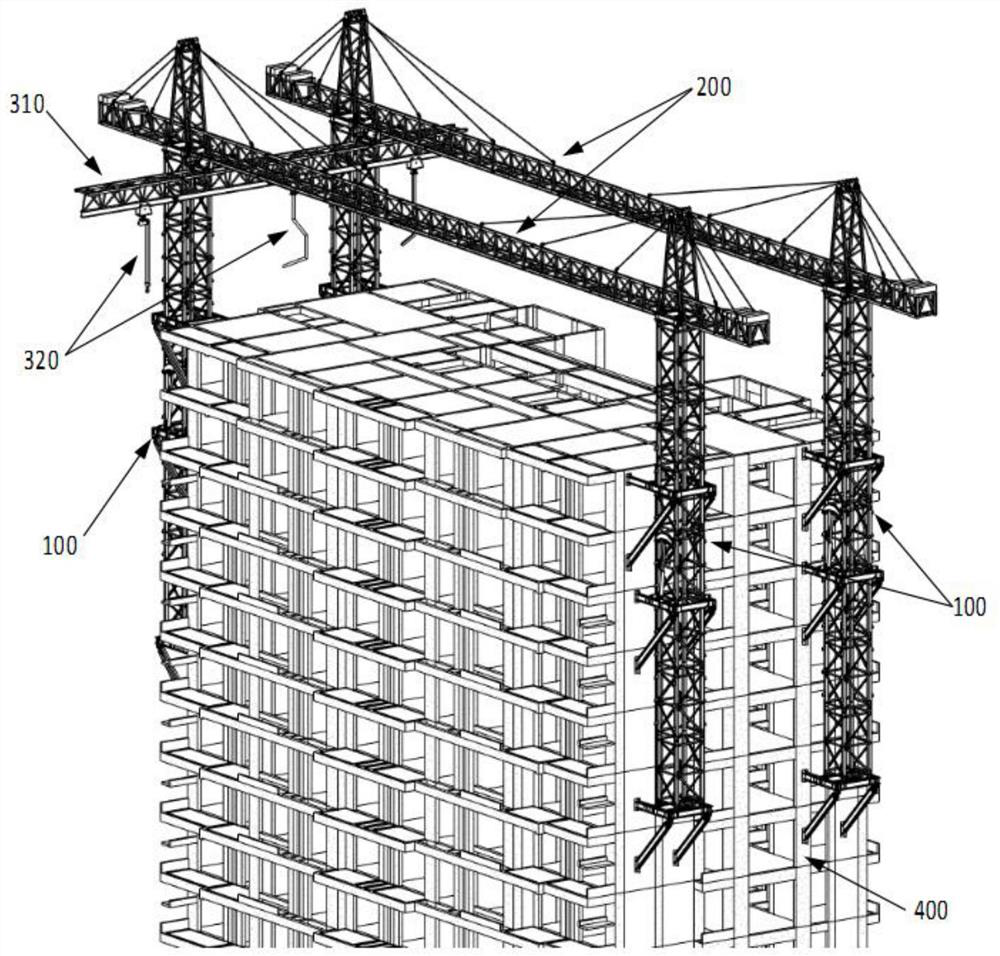

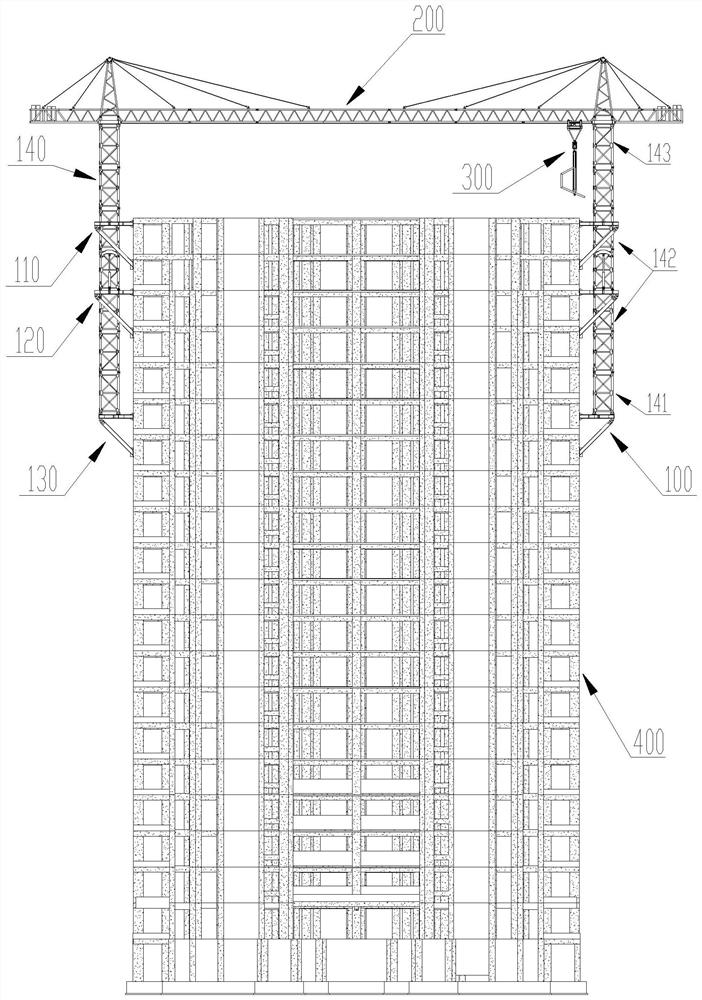

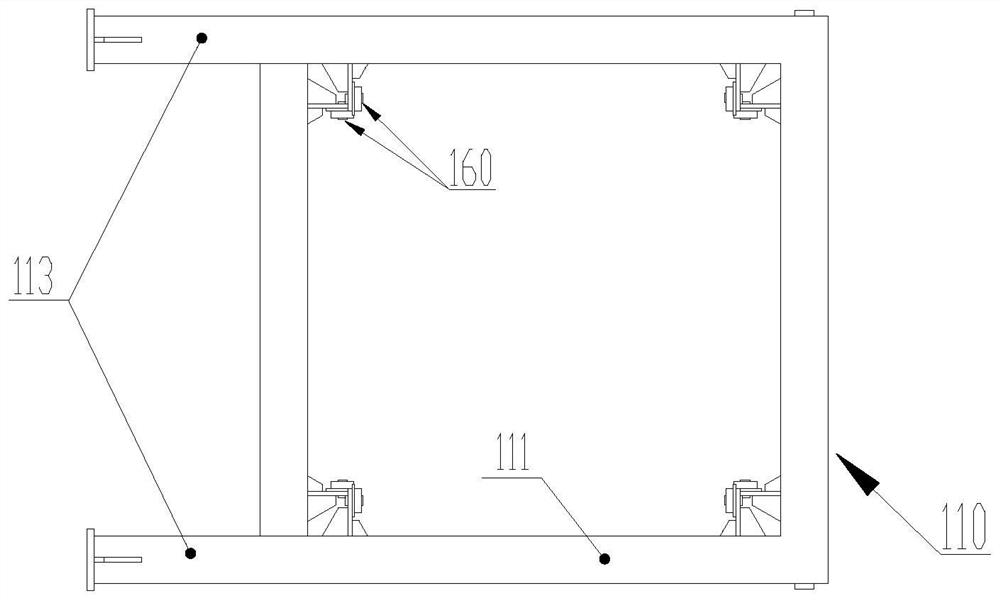

[0180] Such as figure 1 A schematic diagram of a three-dimensional structure of a high-rise building construction system in use provided by an embodiment of the present invention, figure 2 The schematic diagram of the planar structure of a kind of high-rise building construction system provided by the embodiment of the present invention is as follows:

[0181] A high-rise building construction system comprising:

[0182] Self-climbing support subsystem, fixed track truss subsystem and mobile truss operation subsystem;

[0183] The self-climbing support subsystem includes at least four independent self-climbing support structures 100;

[0184] The self-climbing support structure 100 is respectively installed on the supporting base (not shown in the figure) supporting the self-climbing support structure or on the main structure wall 400 of a high-rise building...

Embodiment 2

[0255] This embodiment provides a method for installing and using a high-rise building construction system used for high-rise building construction.

[0256] In this embodiment, the high-rise building construction system includes a self-climbing support subsystem, a fixed track truss subsystem and a mobile truss operation subsystem, and the self-climbing support subsystem includes a self-climbing support structure. The self-climbing support structure includes a load-bearing structure, the fixed track truss subsystem includes a fixed track truss structure, and the mobile truss operation subsystem includes a mobile truss and an operating device.

[0257] The installation and use method of the high-rise building construction system provided in this embodiment includes the installation and use of the self-climbing support structure in the first stage and the second stage, as well as the installation and use of the fixed track truss subsystem and the mobile truss operation subsystem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com