Reverse construction method for pipe-jacking bricked working well

A construction method and technology for working wells, which can be applied to artificial islands, water conservancy projects, infrastructure projects, etc., and can solve problems such as uneconomical construction techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

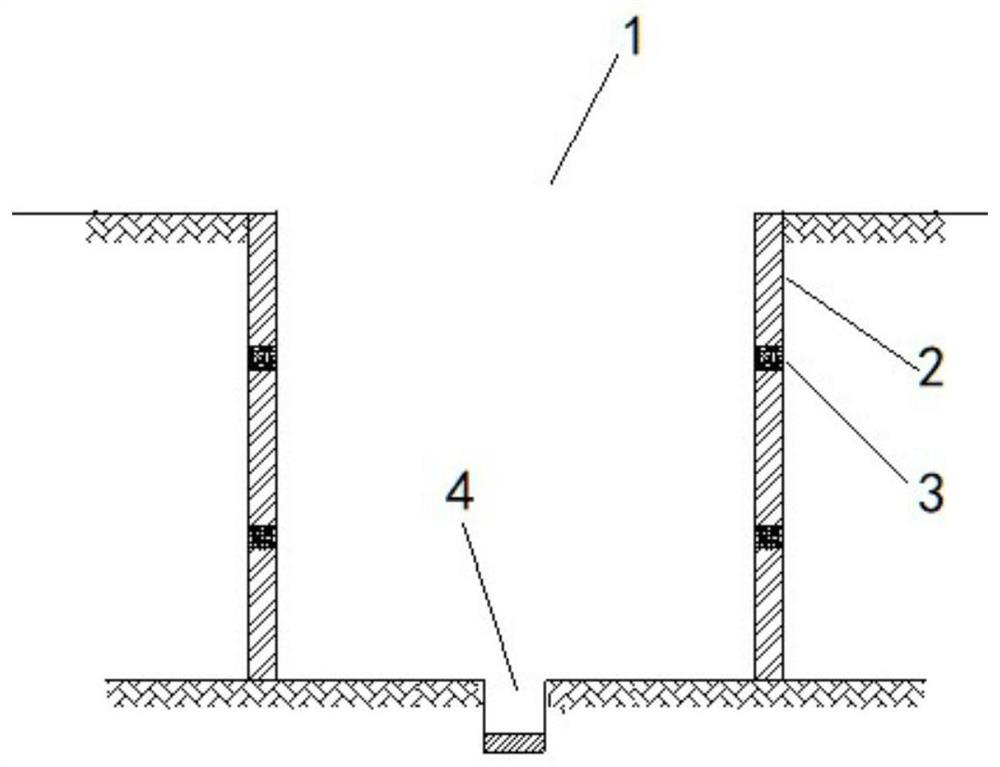

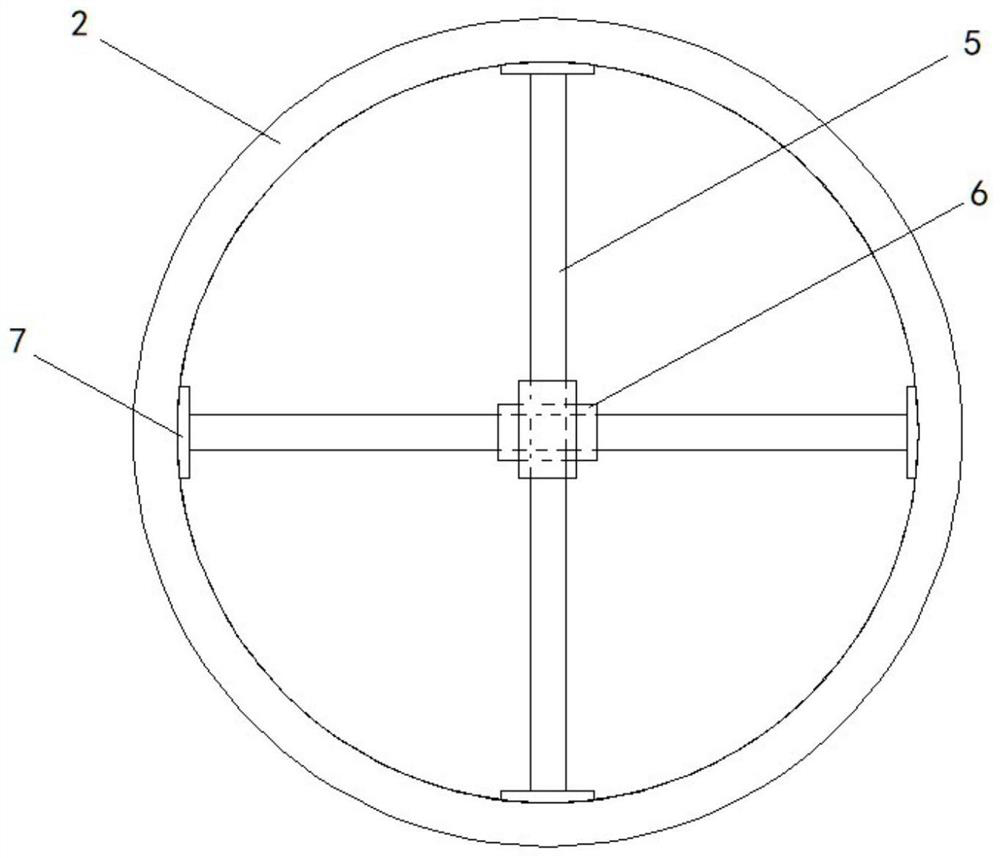

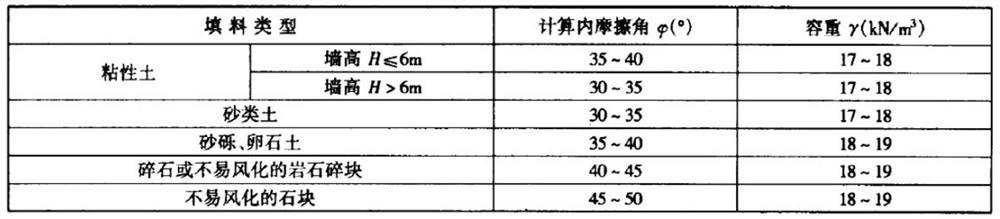

[0033]A top-down construction method for a pipe jacking brick working well. The steps include: 1) determining the thickness of the shaft wall; 2) measuring, laying out and positioning; 3) earthwork excavation; 4) well chamber masonry; 5) well bottom construction 6) Pouring the side walls of the well and 7) Backfilling the well.

[0034]This example uses a pipe jacking construction work well project used in a town’s sewage treatment project as an example to illustrate the method.

[0035]The construction process of this example:

[0036]Determine the thickness of the shaft wall → measurement, laying out, positioning → first layer of earthwork → first layer of reinforced concrete ring beam pouring, shaft wall masonry → control of shaft diameter → second layer of earthwork → second layer of reinforced concrete Ring beam pouring, shaft wall masonry→……→control well chamber diameter→last layer of earthwork→last layer of reinforced concrete ring beam pouring, shaft wall masonry→water pump drainage→...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com