Control method for preventing concrete segregation during large-height-difference downward concrete conveying

A control method and concrete technology, which can be used in earth drilling, underground chambers, non-rotational vibration suppression, etc., can solve the problems of low transportation efficiency and easy pipe blockage, and achieve controllable discharge speed, air removal, and convenient The effect of leveling and heightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A control method for preventing concrete segregation by conveying concrete downwards with a large height difference, the method is realized by the following steps:

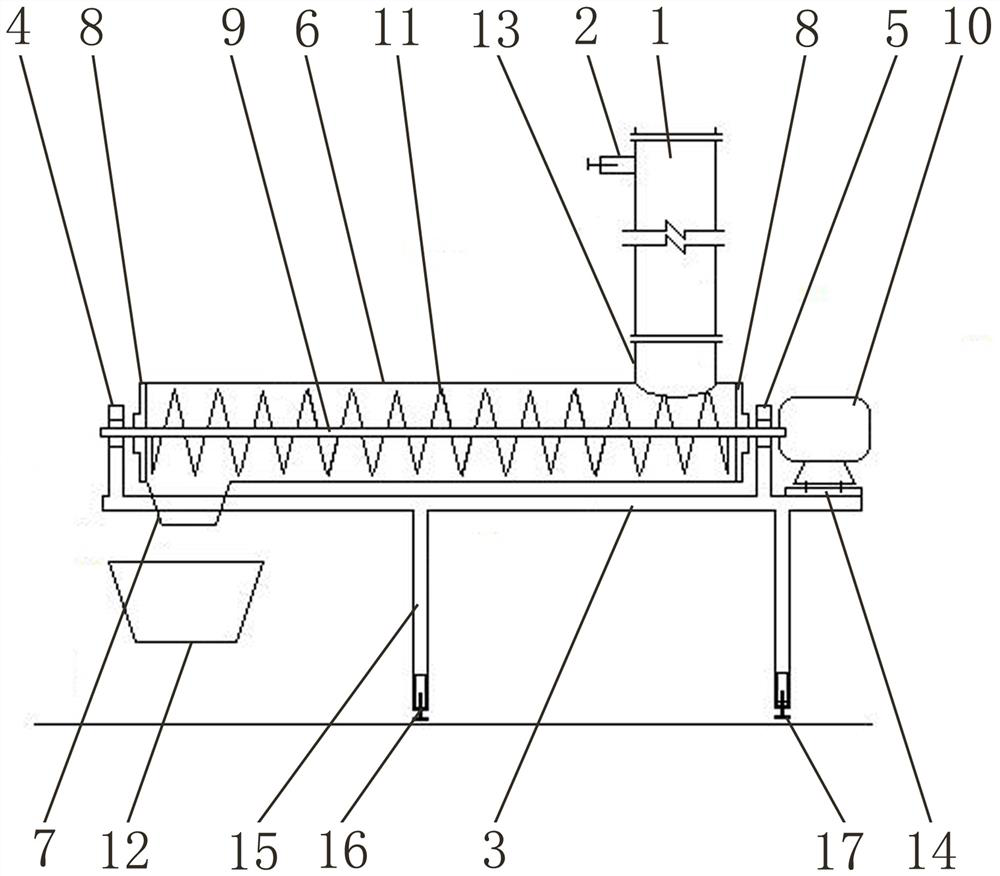

[0029] S1: Assembly of the control device: first install the vertical duct 1, the upper side wall of the vertical duct 1 is provided with an exhaust valve 2, and the lower part is provided with a support platform 3; The left support plate 4 and the right support plate 5, and between the left support plate 4 and the right support plate 5, a horizontal conduit 6 is horizontally installed, and the lower left side wall of the horizontal conduit 6 is fixed with a The discharge hopper 7 and the upper right side wall are provided with a feed port connected to the vertical conduit 1; both ends of the horizontal conduit 6 are fixed with a cover plate 8, and the inner cavity is provided with a rotating shaft passing through the two cover plates 8 9. The side wall of the rotating shaft 9 is fixed with a helical blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com