Asphalt concrete pavement uniform paving and thickness detecting device and using method

A technology for asphalt concrete and thickness detection, which is applied in the direction of measuring devices, roads, roads, etc., can solve the problems that the paving thickness cannot be well controlled and adjusted, the paving height cannot be accurately obtained, and it cannot adapt to large areas. Paving thickness, improving paving efficiency, and controlling the effect of paving thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

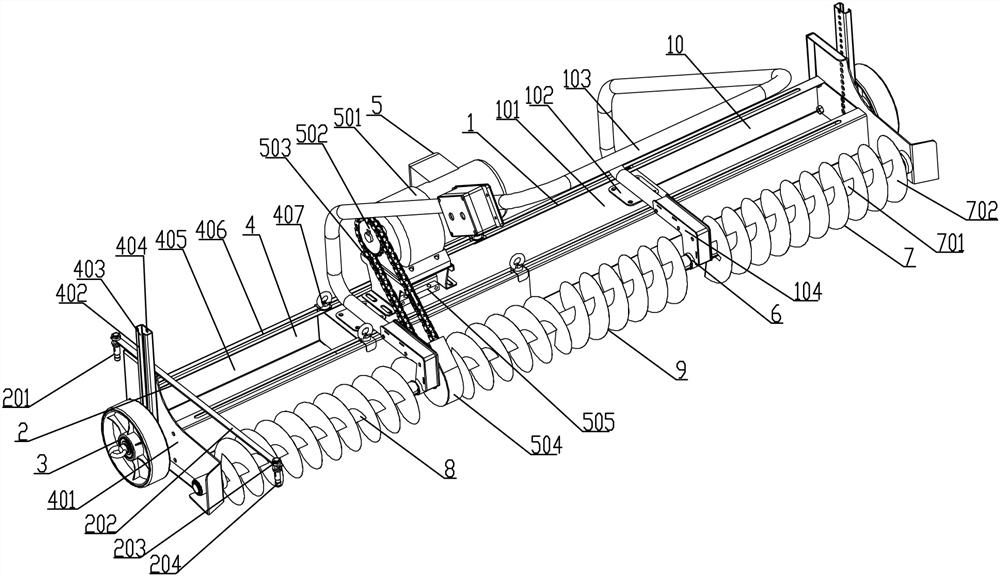

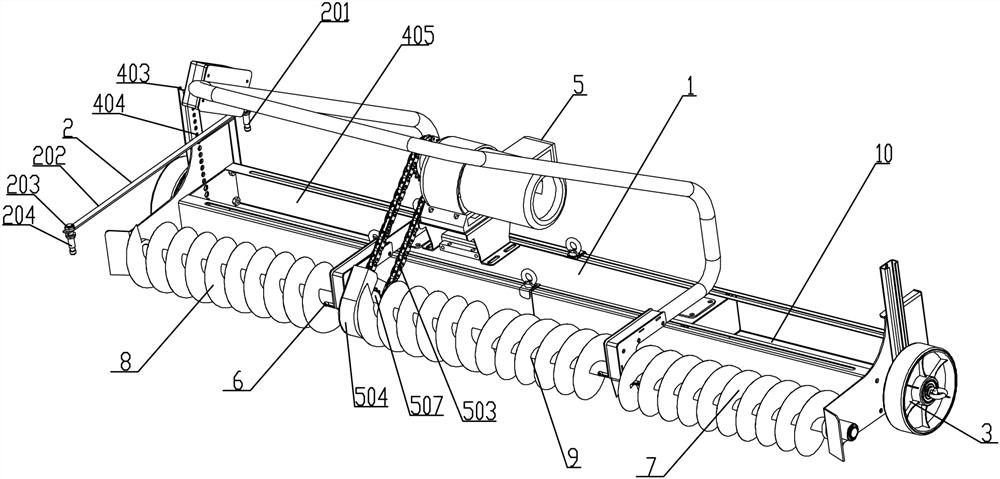

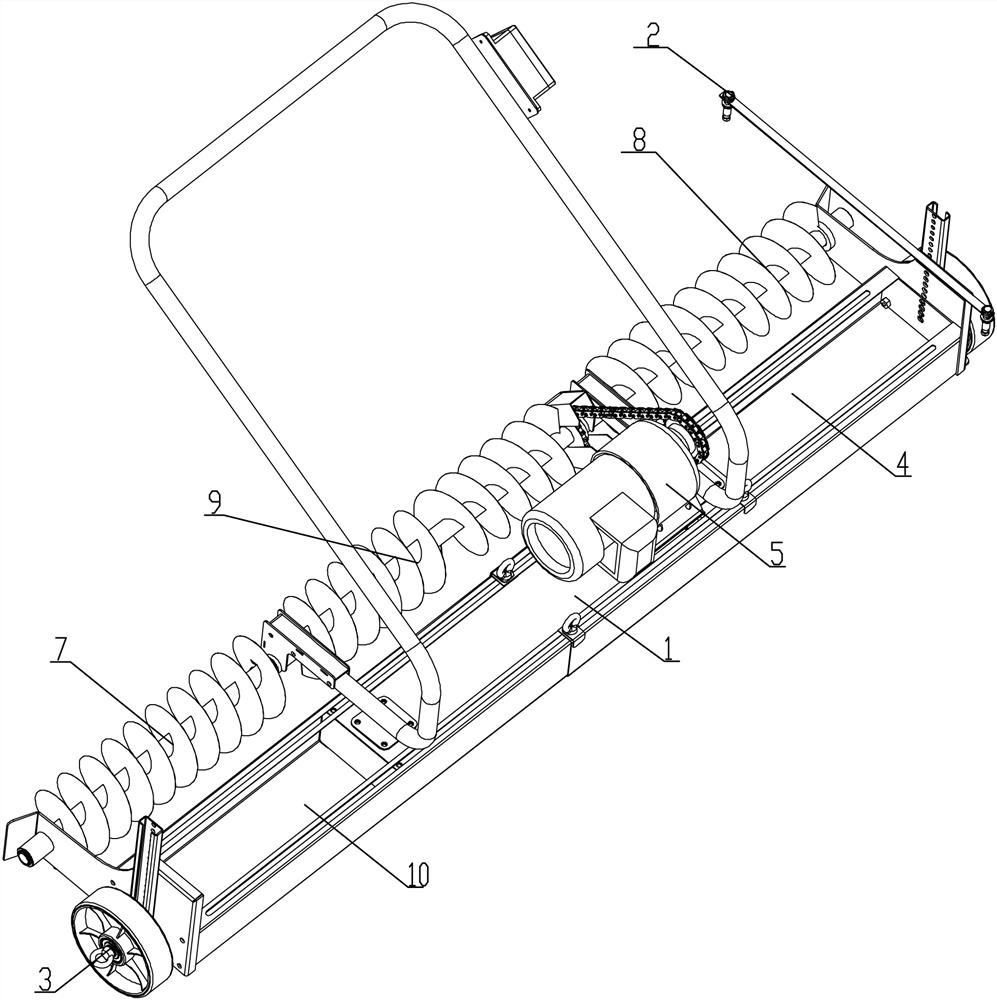

[0048] see Figure 1-9 , asphalt concrete pavement uniform paving and thickness detection device, it includes a main frame structure 1, the two sides of the main frame structure 1 are symmetrically installed with a first box structure 4 and a second box structure 10; in the first box The outer sides of the structure 4 and the second box structure 10 are respectively equipped with walking wheels 3 whose height is easy to adjust through the quick locking mechanism 11; the first box structure 4 is equipped with a thickness detection device 2 for real-time detection of paving thickness A middle hinge cage structure 9 is installed between the main frame structures 1 through a mandrel drive assembly 6, and a first outer hinge cage structure 8 and a second outer hinge cage structure 7 are respectively connected to both sides of the middle hinge cage structure 9 The other end of the first outer hinge cage structure 8 is rotatably supported on the first box structure 4, and the other e...

Embodiment 2

[0058] The method for using the asphalt concrete pavement uniform paving and thickness detection device comprises the following steps:

[0059] Step 1: During the paving process of the asphalt concrete pavement, by dragging the crossbar 103 and adopting the installation method of manually pushing or fixing it at the rear of the engineering vehicle, the whole device is driven to move along the paved road surface;

[0060] Step 2: During walking, start the hinge cage power device 5, drive the middle hinge cage structure 9 through the hinge cage power device 5, and synchronously drive the first outer hinge cage structure 8 and the second outer hinge cage structure 9 through the middle hinge cage structure 9 Structure 7, leveling the asphalt concrete that needs to be leveled through the hinge cage structure;

[0061] Step 3: During the leveling process, the height M of the road surface to be paved is detected in real time by the second height sensor 204, and the height H of the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com