Preparation method of simulated leather grain surface layer nanofiber biomimetic membrane

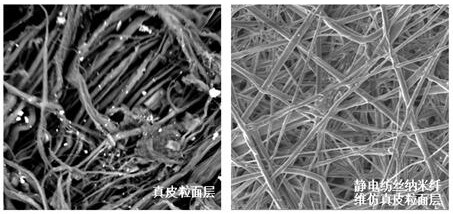

A technology of nanofiber and grain layer, applied in fiber treatment, coating, non-woven fabrics, etc., can solve the problem that the physical and chemical properties of the second layer leather are not as good as the top layer leather, and achieve good air permeability and water vapor permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

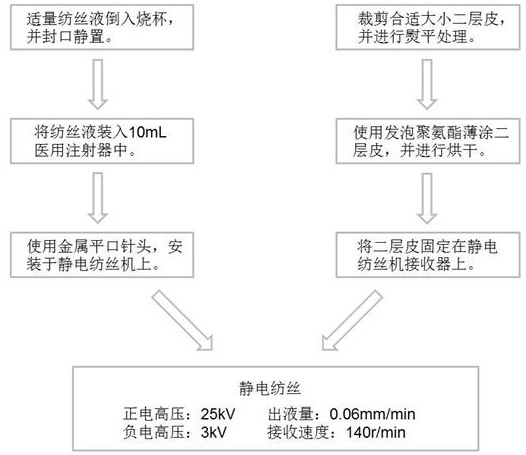

[0029] Take solvent-based polyurethane (6008D, Asahikawa Chemical Co., Ltd.) as an example for spinning solution. Put the polyurethane in a 10mL needle-free medical syringe, install a metal flat needle and connect it to a positive high voltage. Fix the two-layer leather with foam coating on the electrospinning receiver with scotch tape, and connect the negative high voltage. Start the electrospinning machine, and spin under the condition of ambient temperature of 30°C, humidity of about 40%, injection speed of 0.06mm / min, receiving speed of 140r / min and ventilation.

Embodiment 2

[0031] Dilute twice with solvent-based polyurethane (6008D, Asahikawa Chemical Co., Ltd.) as the spinning solution. Put the polyurethane in a 10mL needle-free medical syringe, install a metal flat needle and connect it to a positive high voltage. Fix the two-layer leather with foam coating on the electrospinning receiver with scotch tape, and connect the negative high voltage. Start the electrospinning machine, and spin under the condition of ambient temperature of 40°C, humidity of about 40%, injection speed of 0.06mm / min, receiving speed of 50r / min and ventilation.

Embodiment 3

[0033] Take solvent-based polyurethane (6030K, Asahikawa Chemical Co., Ltd.) as an example for spinning solution. Put the polyurethane in a 10mL needle-free medical syringe, install a metal flat needle and connect it to a positive high voltage. Fix the two-layer leather with foam coating on the electrospinning receiver with scotch tape, and connect the negative high voltage. Start the electrospinning machine, and spin under the condition of ambient temperature of 30°C, humidity of about 40%, injection speed of 0.06mm / min, receiving speed of 140r / min and ventilation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com