Anti-glare glass production device with safety protection and stabilization base

A technology for safety protection and production equipment, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problem of lack of protective structure outside the shell, and achieve the effect of improving crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

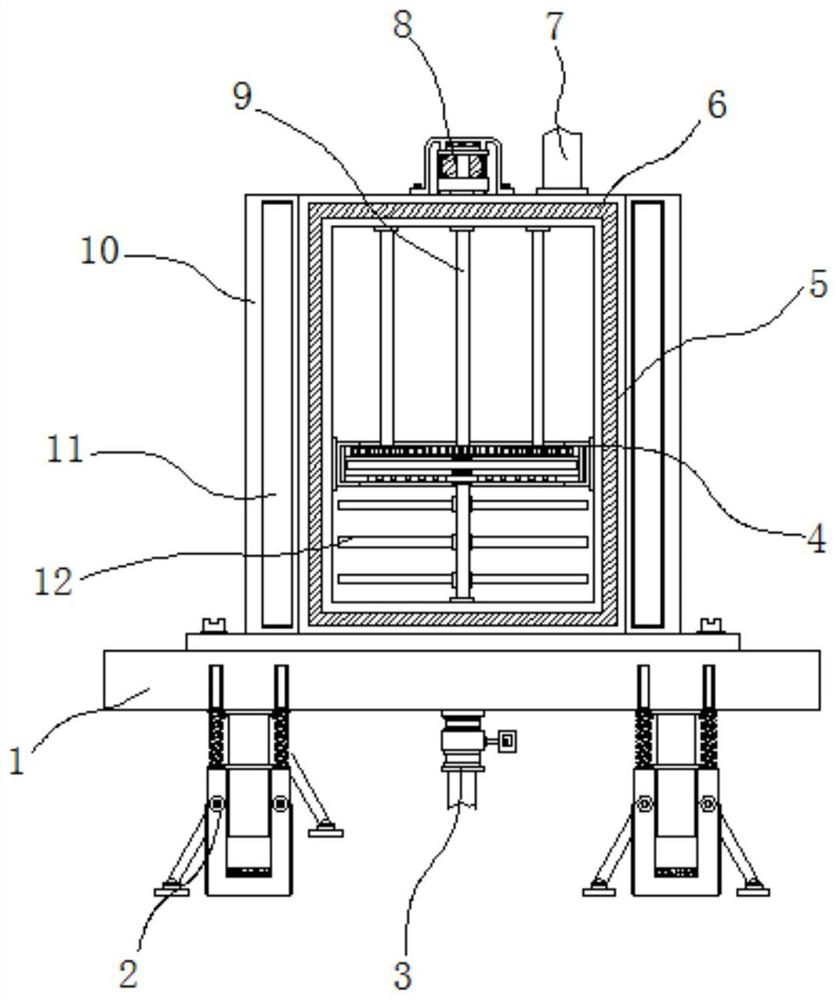

[0026] Example 1: See Figure 1-5 , an anti-glare glass production device with safety protection and a stable base, comprising a base 1, a discharge valve 3 and a housing 5, the four corners at the bottom of the base 1 are respectively fixedly connected with a support structure 2, the base The top end of the seat 1 is fixedly connected with the housing 5, and the bottom end of the housing 5 passes through the base 1 and is fixedly connected with the discharge valve 3. The inside of the outer side of the housing 5 is provided with a heating layer 6, and the top and bottom of the housing 5 are connected to each other. The middle position between the ends is movably connected with a transmission rod 9, and the top end of the transmission rod 9 passes through the housing 5 and is fixedly connected with a servo motor 8. The model of the servo motor 8 can be Y2-80M2-4, and the middle of the transmission rod 9 There is a pulverizing structure 4 between the position and the housing 5....

Embodiment 2

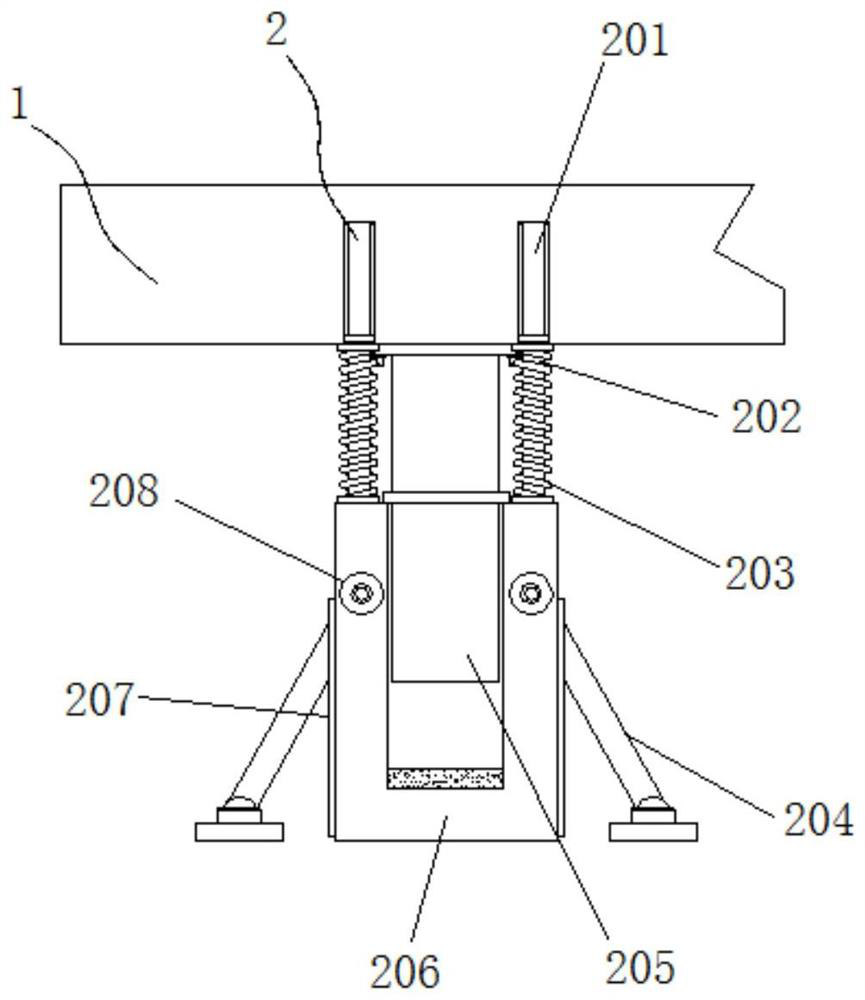

[0029] Embodiment 2: The support structure 2 is composed of a slot 201, an insertion rod 202, a buffer spring 203, a side bar 204, a pillar 205, a sleeve 206, a receiving groove 207 and a fastening bolt 208. The slots 201 are respectively arranged on the base 1 At the four corners of the bottom end, an insertion rod 202 is arranged inside the slot 201, and a sleeve 206 is fixedly connected between the bottom ends of the insertion rod 202, and four sets of buffer springs 203 are arranged between the sleeve 206 and the base 1 , the inside of the sleeve 206 and the base 1 are movably connected with a pillar 205, four sets of storage grooves 207 are arranged on the outside of the sleeve 206, and the inside of the storage groove 207 is provided with a side rod 204, and the connection between the side rod 204 and the sleeve 206 There are fastening bolts 208 in the movable connection;

[0030] The diameter of the insertion rod 202 is smaller than the inner diameter of the slot 201, a...

Embodiment 3

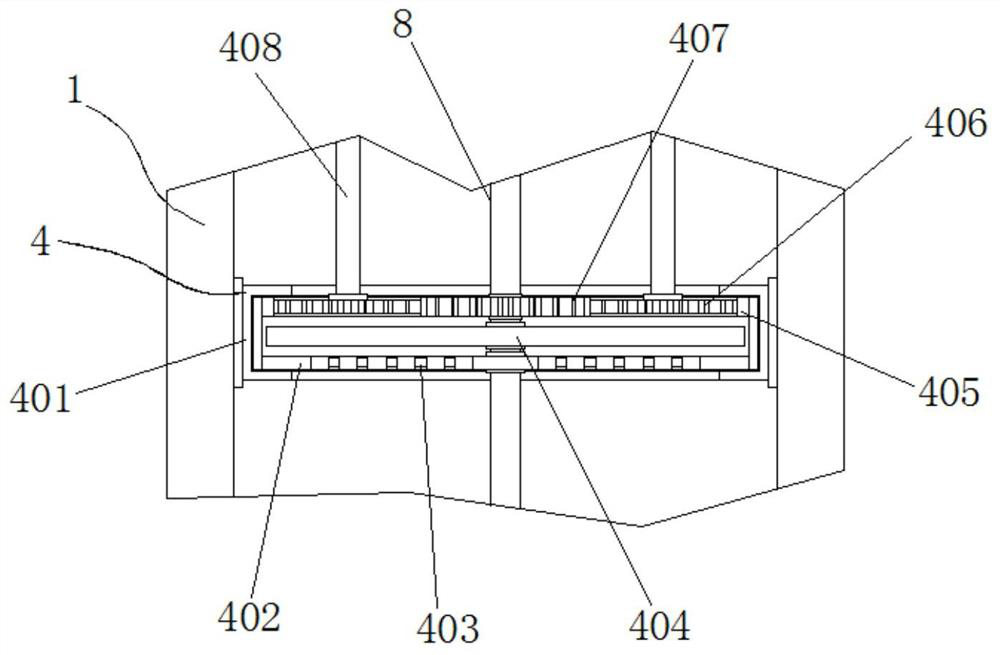

[0032]Embodiment 3: The crushing structure 4 is composed of a limiting groove 401, a turntable 402, a hole 403, a sweeping rod 404, a tooth block 405, a first gear 406, a second gear 407 and a connecting rod 408. The limiting groove 401 is fixedly connected to the shell At the middle position inside the body 5, the inside of the limiting groove 401 is movably connected with a turntable 402, and the bottom end of the turntable 402 is provided with a plurality of groups of holes 403, and the sweep rod 404 is fixedly connected at the middle position of the transmission rod 9, and the top end of the turntable 402 is There are multiple sets of gear blocks 405 fixedly connected inside the housing 5, the connecting rods 408 are respectively fixedly connected to the two sides of the top inside the housing 5, the bottom end of the connecting rods 408 is fixedly connected to the first gear 406, and one side of the first gear 406 A second gear 407 is movably connected between them;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com